Panel door lock structure

A door lock structure and panel lock technology, which is applied in building locks, building structures, buildings, etc., can solve the problems of not being able to install the lock cylinder cover, reduce production efficiency, time-consuming and process-consuming, and achieve the improvement of production management level and Production efficiency, convenient matching effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

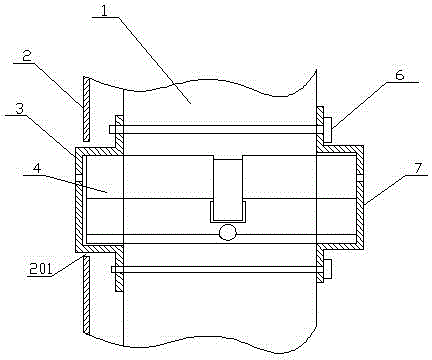

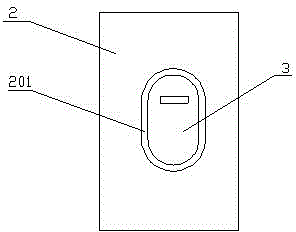

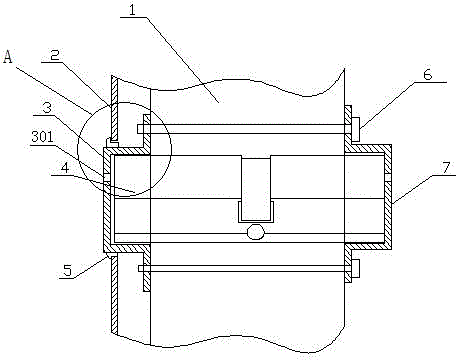

[0015] See image 3 —— Figure 5 , a panel door lock structure, including a panel 2 with a keyhole, a lock cylinder cover 3 with a keyhole 301 and a decorative ring 5, the lock cylinder cover 3 is arranged in the lockhole of the panel 2, and the decoration The ring 5 is sleeved on the lock cylinder cover 3. The decorative ring 5 includes an annular body 501 and an annular cover plate 502 extending radially outward from one end of the body 5. The size of the inner ring of the body 5 is the same as that of the The external dimensions of the lock cylinder cover 3 are consistent, the radial width L of the cover plate 502 is 2.5mm-5mm, and the cover plate 502 of the decorative ring 5 closes the gap between the lock cylinder cover 3 and the panel lock hole. 201 covered.

[0016] When the present invention is installed, the lock cylinder 4 is installed in the door leaf 1, and the front and rear lock cylinder protective covers 3 and 7 are fixed on the front and rear sides of the doo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com