Industrial robot performance measurement method

A technology of industrial robots and measurement methods, applied in measurement devices, instruments, etc., can solve the problems of long measurement time, complicated operation process, and low measurement accuracy, and achieve the effect of short measurement time, high measurement accuracy, and high technical level requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

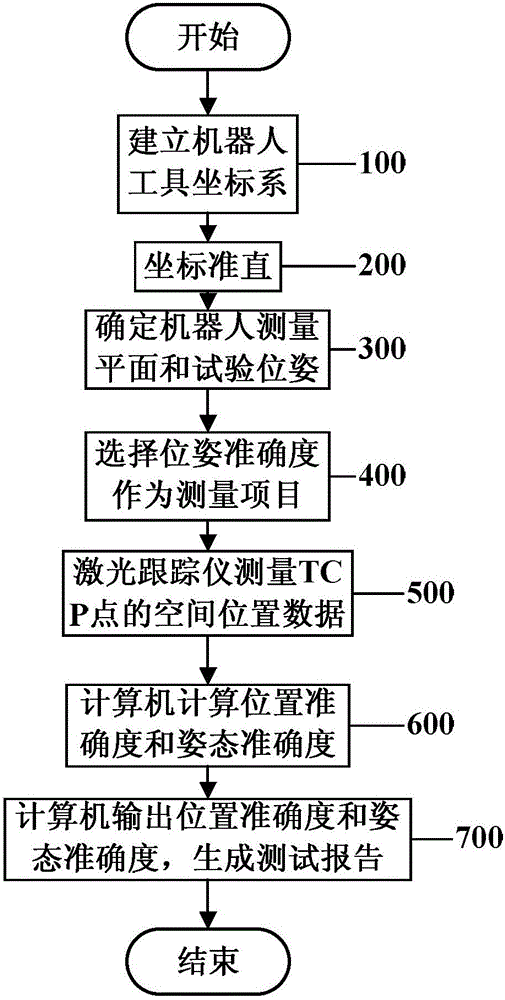

[0048] Such as figure 1 The illustrated embodiment is a method for measuring the performance of an industrial robot, comprising a laser tracker, a computer and a teach pendant located on the robot, and the computer is electrically connected to the laser tracker and the teach pendant respectively; comprises the following steps:

[0049] Step 100, establish robot tool coordinate system

[0050] Fix 5 laser target balls on the fixture at the end of the robot, select one of the target balls as the TCP point, and move the robot to 10 positions in the motion space that are not on the same straight line in turn, and the posture of the robot at each position is adjusted. Variety;

[0051] Laser tracker measures 10 sets of position data of TCP points m(i)=(xm(i), ym(i), zm(i)), i=1, 2,...,10;

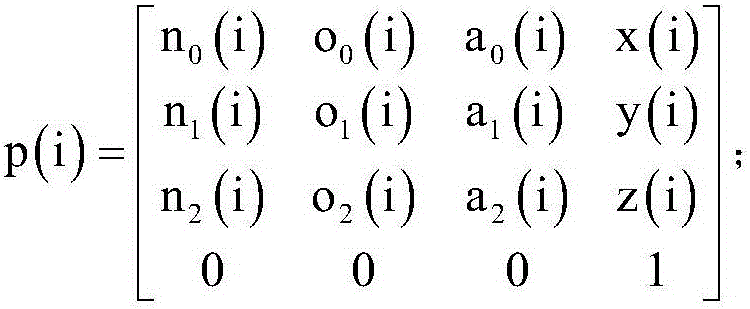

[0052] The computer reads 10 sets of pose data at the end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com