Test device for hydraulic multi-way valve of tractor and test method thereof

A test device and multi-way valve technology, applied in the direction of fluid pressure actuation device, fluid pressure actuation system test, mechanical equipment, etc., can solve problems such as poor cleanliness, damage to the matching sealing surface, difficulty in valve stem reset, etc., to achieve Reasonable design, high yield rate, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Below in conjunction with accompanying drawing, the present invention is described in further detail:

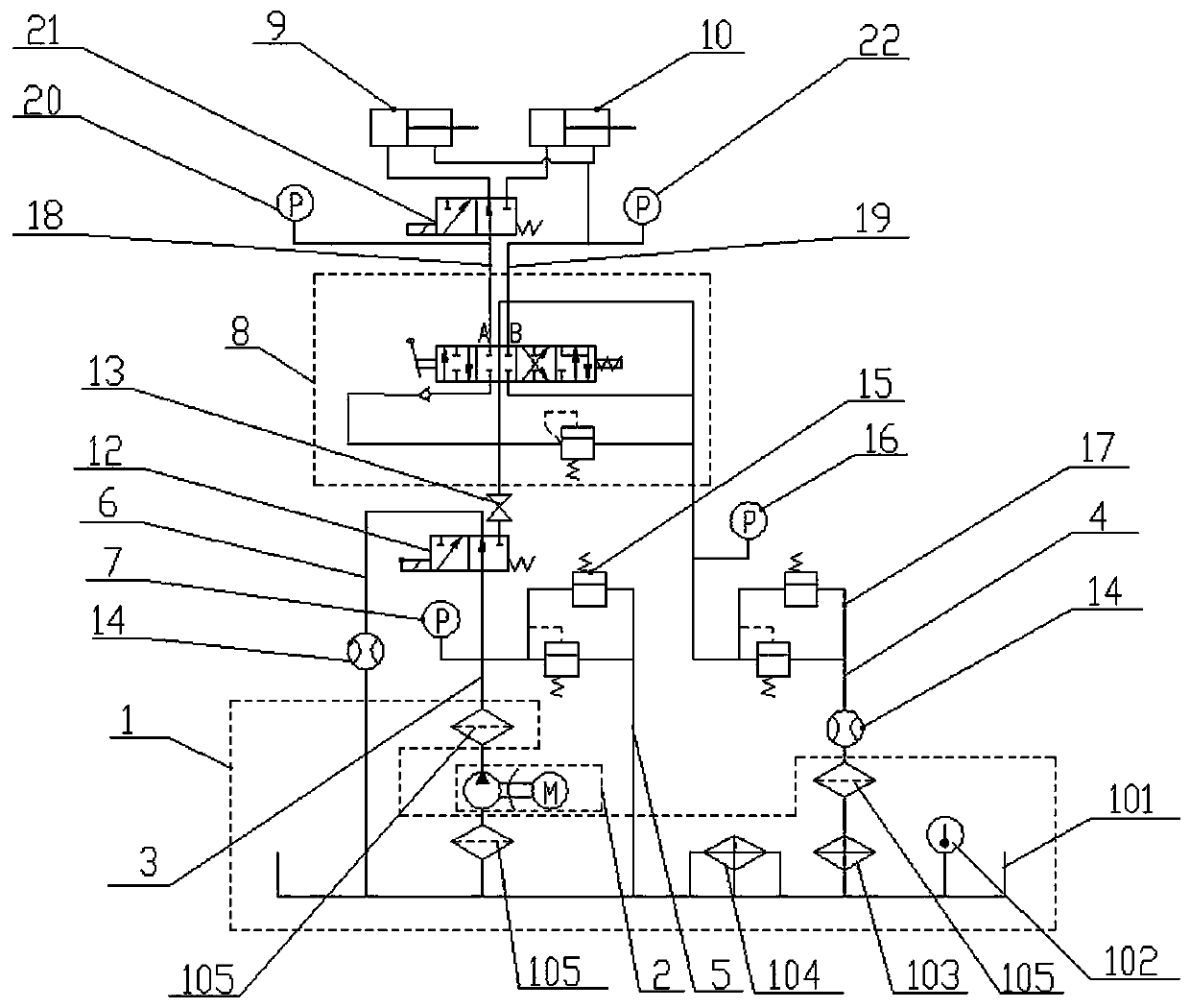

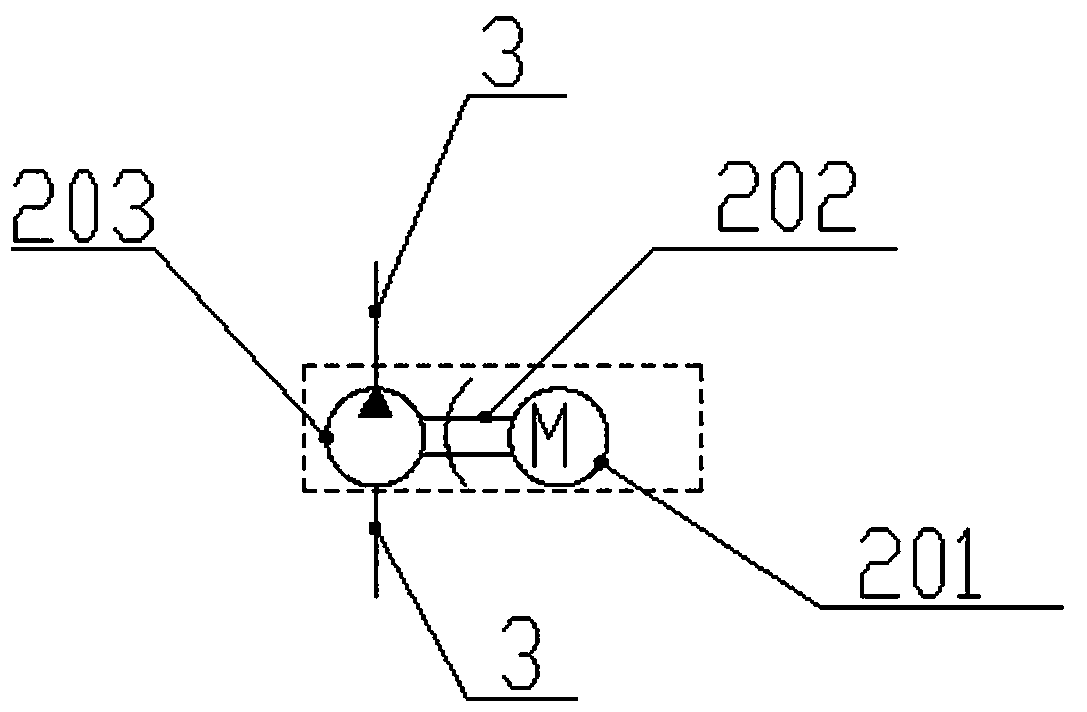

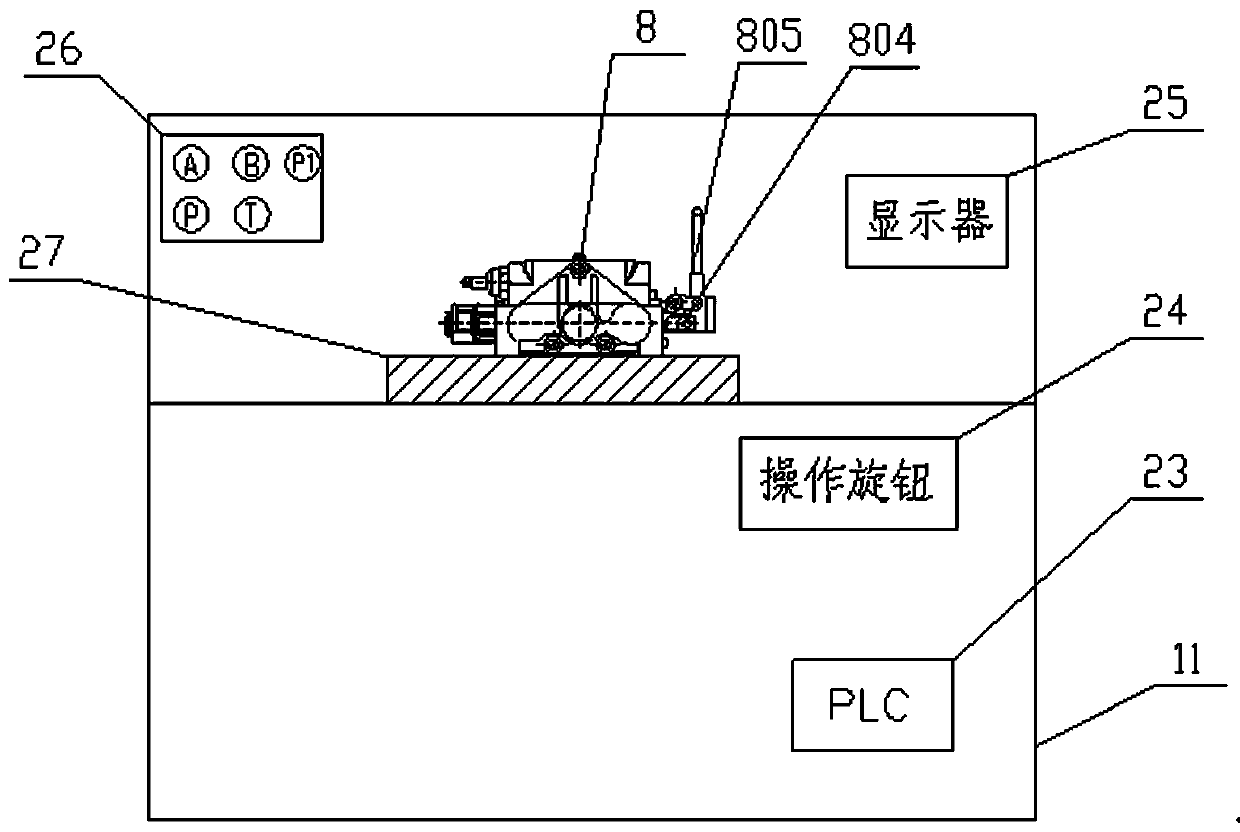

[0031] As shown in the figure, a tractor hydraulic multi-way valve test device includes a fuel tank assembly 1, a power assembly 2, a PLC control assembly, a multi-way valve to be tested 8, a simulated load cylinder 9, a lifter 10 and a box-type base 11. , the multi-way valve 8 to be tested and the PLC control assembly are all arranged on the box-type base 11, the fuel tank assembly 1 and the box-type base 11 are installed on the ground; the power assembly 2 is installed on the fuel tank assembly 1; The three-way solenoid valve I12 and the two-position three-way solenoid valve II21 are respectively connected between the power assembly 2 and the multi-way valve 8 to be tested, and between the multi-way valve 8 to be tested and the simulated load cylinder 9 and the lifter 10; the thermometer 102 is installed In the hydraulic oil tank 101; the flow meter 14 is installed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com