Method for determining number of required screws of circular-cross-section rubber strip in compressed state

A determination method and technology of rubber strips, applied in the testing of mechanical parts, testing of fluid tightness, testing of machine/structural parts, etc. inappropriate type

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0060] In order to make the purpose, technical solutions and advantages of the present invention clearer, the implementation manners of the present invention will be further described in detail in conjunction with the accompanying drawings.

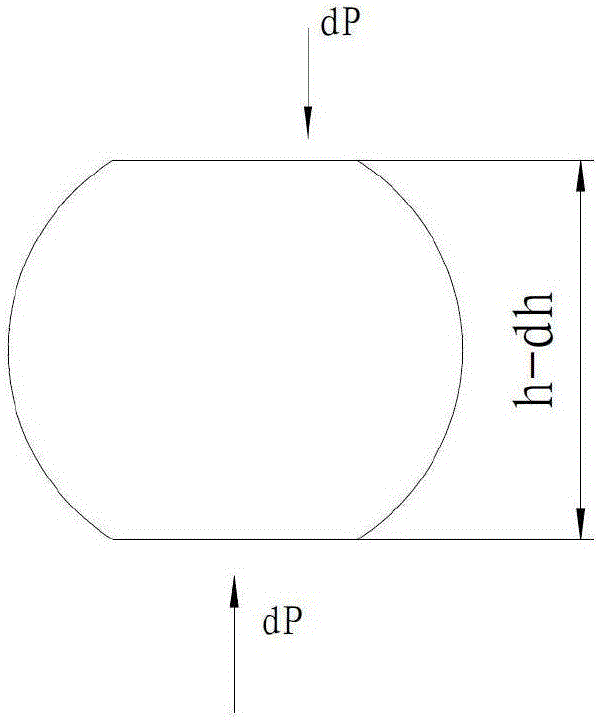

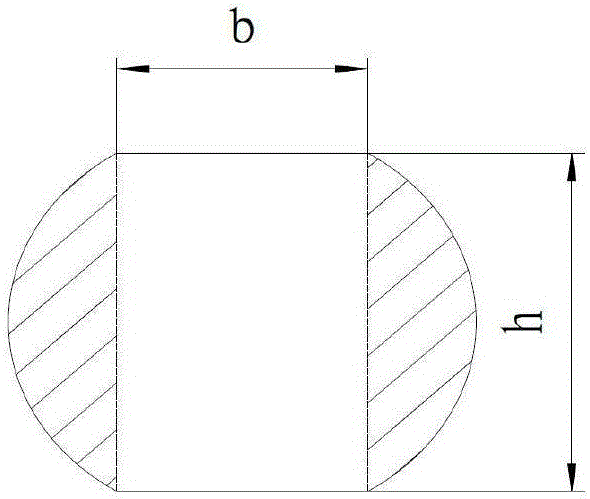

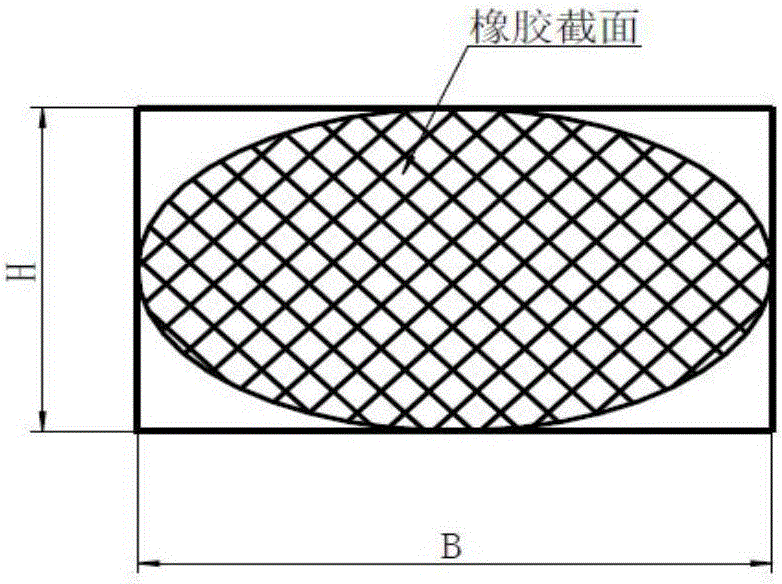

[0061] Step 1: convert the hardness of the circular cross-section rubber strip into the elastic modulus of the circular cross-section rubber strip; the process of the circular cross-section rubber strip being compressed and deformed is elastic deformation (without considering plastic deformation), and the suffered pressure is about The continuous function of the height of the circular section rubber strip; due to the particularity of the rubber material, it is much easier to measure its hardness than to measure its elastic modulus, so the manuals of various rubbers generally only mark the hardness of the rubber, which is often used in practical applications To elastic modulus, therefore need to know the relation of elastic modulus and hard...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com