Battery module

A battery module and end plate technology, which is applied to battery pack components, circuits, electrical components, etc., can solve the problems of reduced installation efficiency, poor flatness of the upper end surface, and increased difficulty in locking bolts and bases, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present application will be further described in detail below through specific embodiments in conjunction with the drawings.

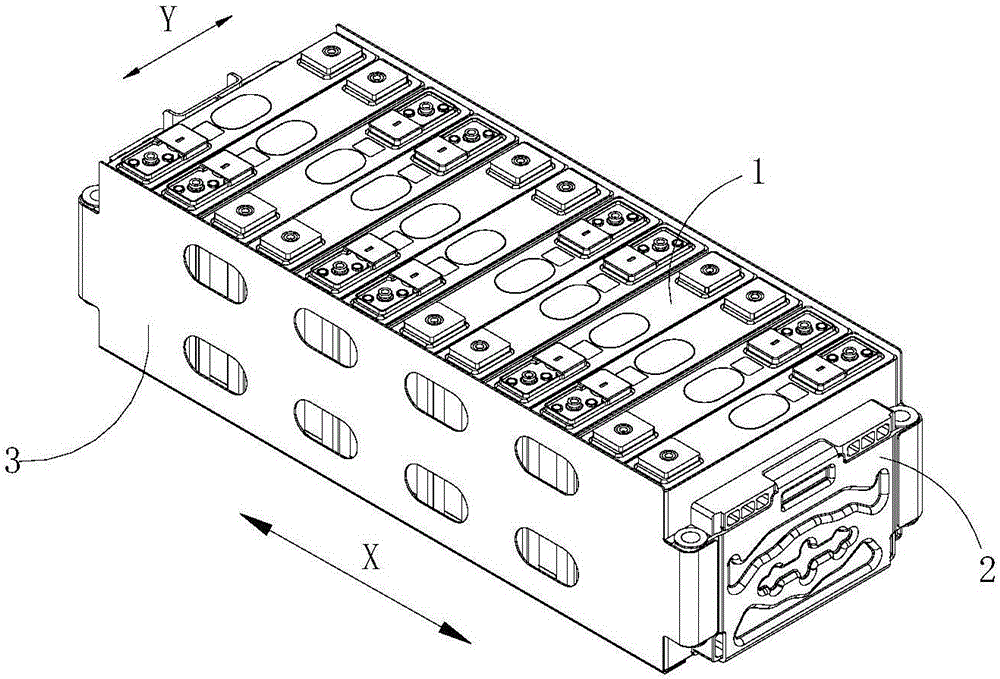

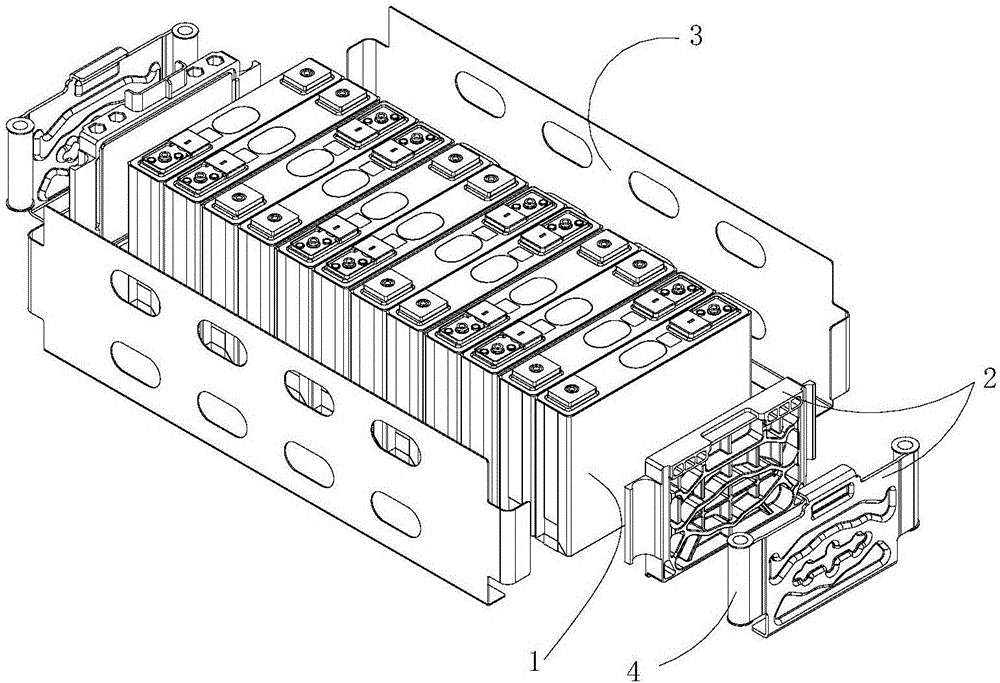

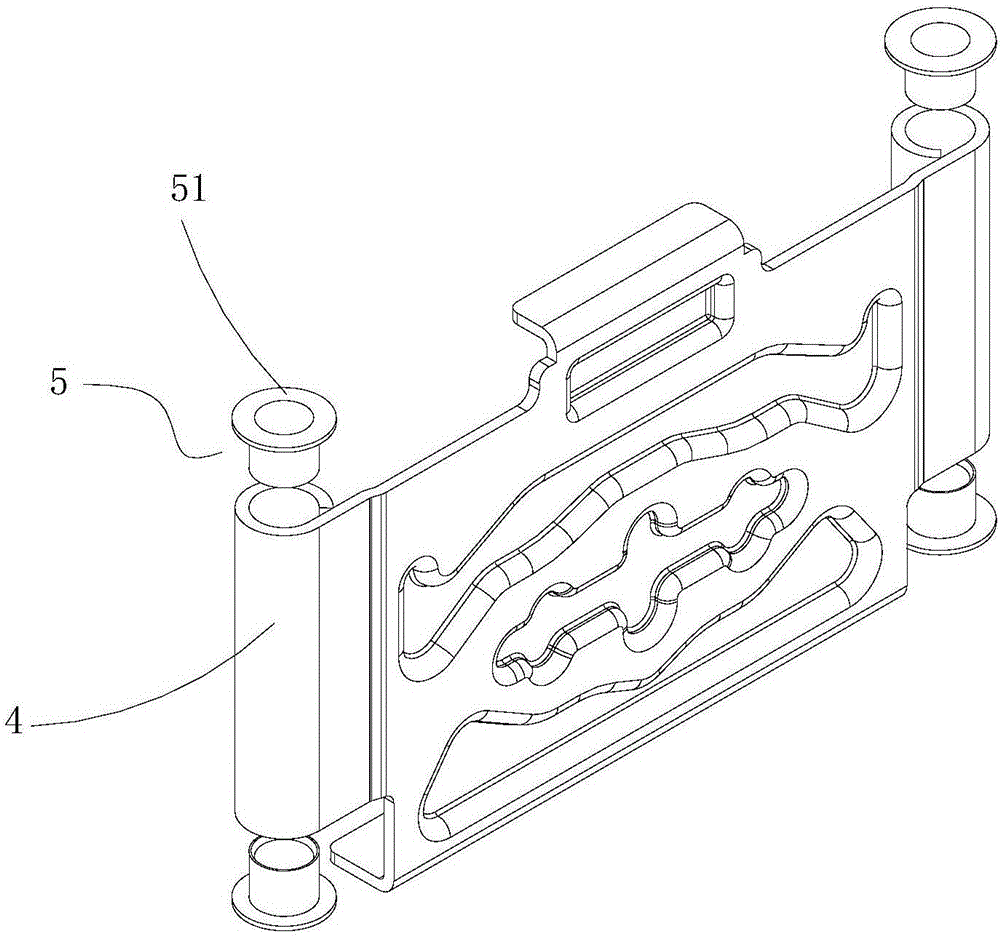

[0047] Such as Figure 1-2 As shown, the embodiment of the present application provides a battery module including a base (not shown in the figure), a plurality of battery units 1, a pair of end plates 2, a pair of side plates 3, and a plurality of sleeve members.

[0048] A plurality of battery cells 1 are located on the base and stacked along the thickness direction of the battery cell 1 according to the requirements of the series and parallel connection of the battery module, and the width faces are closely attached; a pair of end plates 2 are respectively located in the thickness direction of the plurality of battery cells 1 ( figure 1 In the X direction), and adjacent to the outermost battery cell 1 of the plurality of battery cells 1, and along the width direction of the battery cell 1 ( figure 1 In the Y direction) extends; a pair of side p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com