Multifunctional combined printing device

A printing device and multi-functional technology, applied in the direction of additive processing, etc., can solve problems such as the inability to manufacture full-color 3D products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0074] Some typical embodiments embodying the features and advantages of the present invention will be described in detail in the description in the following paragraphs. It should be understood that the present invention can have various changes in different aspects without departing from the scope of the present invention, and that the description and illustrations therein are illustrative in nature and not restrictive this invention.

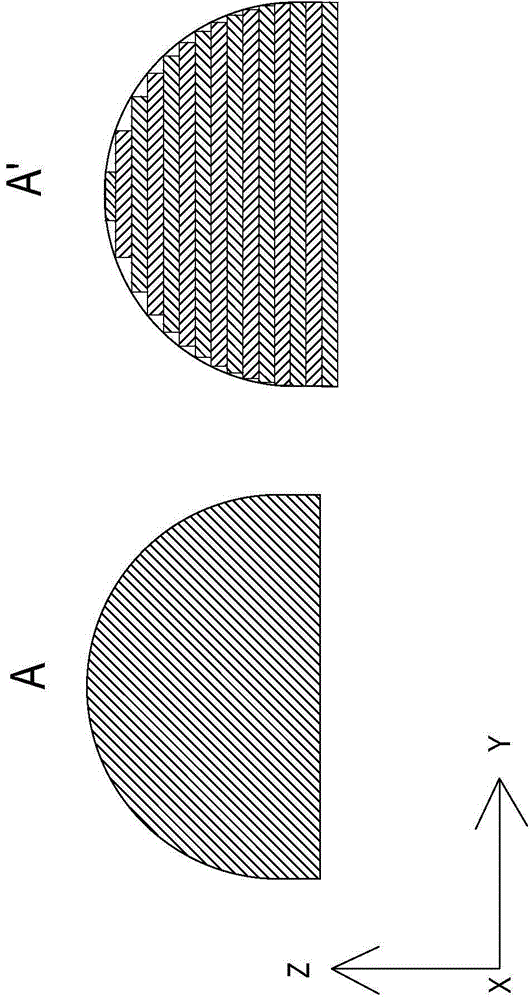

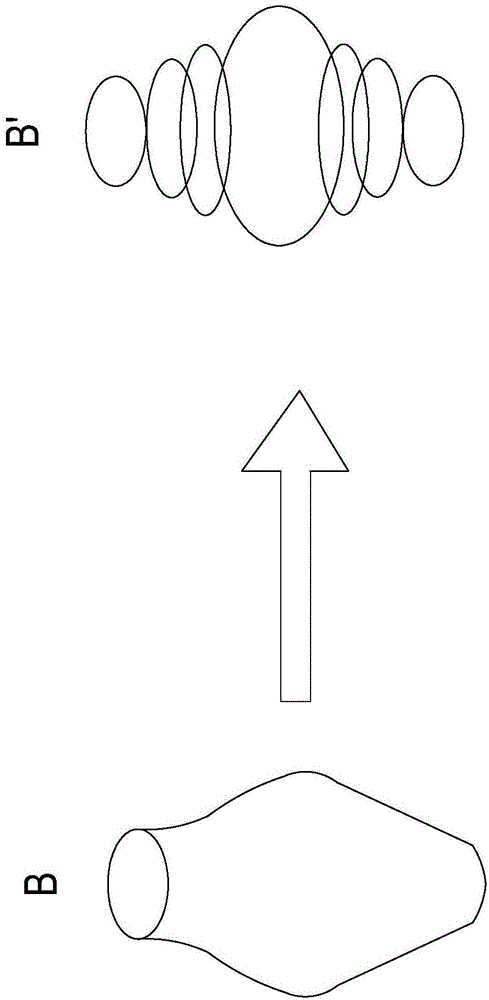

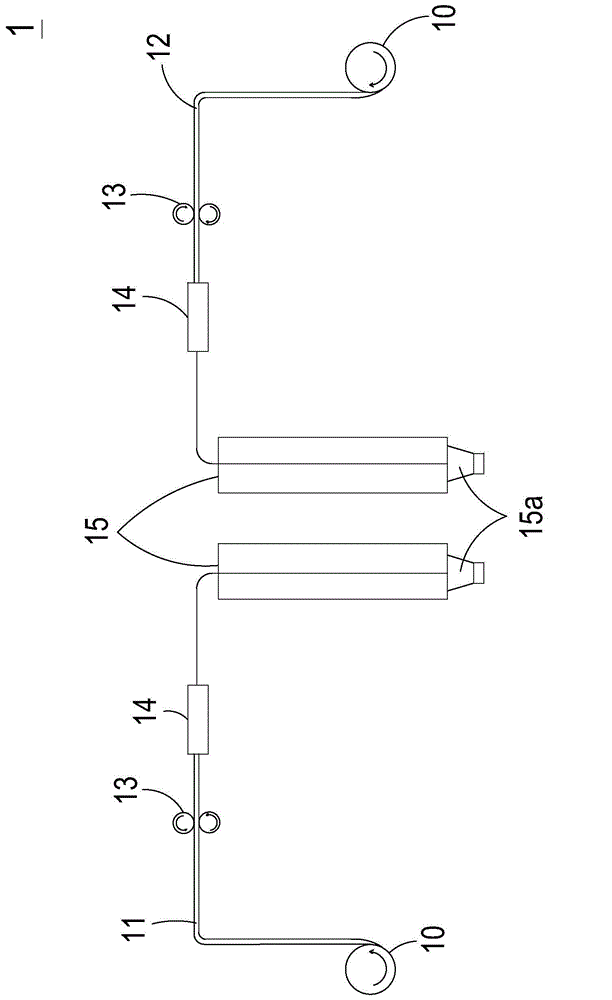

[0075] see Figure 4 , which is a schematic diagram of a molding device suitable for a fused deposition modeling machine and a multifunctional composite printing device thereof according to the first preferred embodiment of the present invention. Such as Figure 4 As shown, the multifunctional composite printing device 20 of the present invention is suitable for use in a fused deposition modeling (FDM) machine 2, and the forming device 25 of the fused deposition modeling (FDM) machine 2 has a multifunctional composite printing device 20, at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com