Rope Clamp Fixing Block

A technology for fixing clips and rope clamps, applied in elevators, transportation and packaging, etc., can solve problems such as excessive deceleration due to gravity, inconvenient release of wedge-shaped rope clamps, etc., to avoid complicated operations, improve maintenance work efficiency, and shorten failures. The effect of repair time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

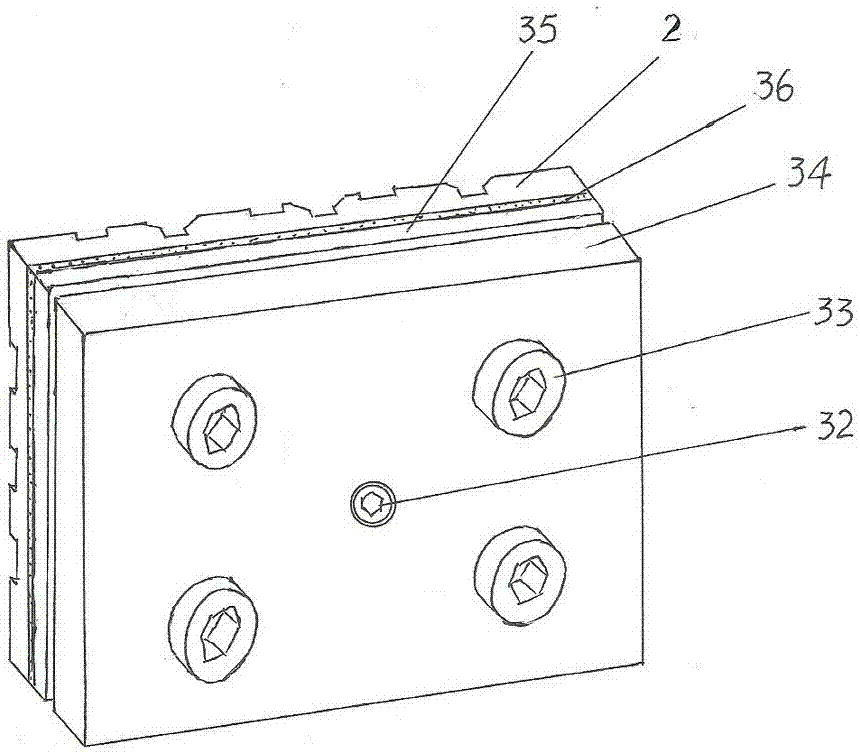

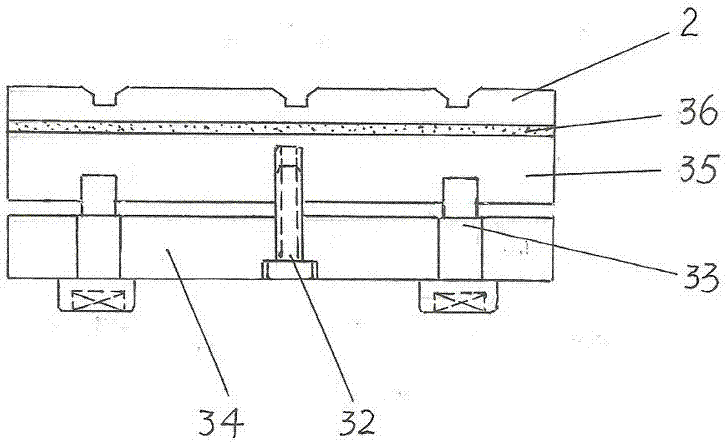

[0017] Such as figure 1 , figure 2 As shown, the present invention includes parts such as backboard 34, front board 35 and friction plate 2; Backboard 34 and front board 35 are all rectangular plates made of thick steel plates, and backboard 34 is fixed on the frame of rope gripper , so that the fixing clamp block is connected with the frame. The front plate 35 is arranged on the front of the back plate 34 , and the friction plate 2 is arranged on the front of the front plate 35 . A rectangular four corners on the board surface of the back plate 34 are respectively provided with four through large-diameter screw holes, and a brake release screw 33 is threaded through each of the four screw holes, and the front end of the brake release screw 33 is screwed on the The opening is in the screw hole on the corresponding position on the back of the front plate 35 . One or two small-diameter screw holes are opened at the center position on the plate surface of the back plate 34, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com