An inner pressure foot device of a sewing machine

A sewing machine and internal pressure technology, which is applied in the direction of sewing machine components, sewing equipment, cloth pressing mechanism, etc., can solve the problems of increasing the overall volume of the internal presser foot device and increasing the cost of guiding components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

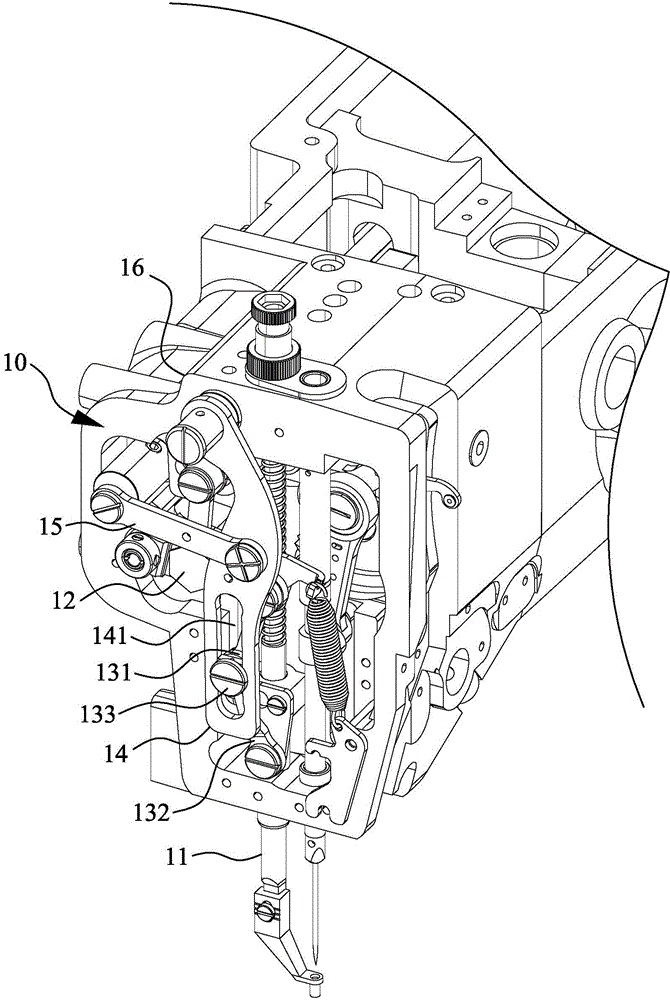

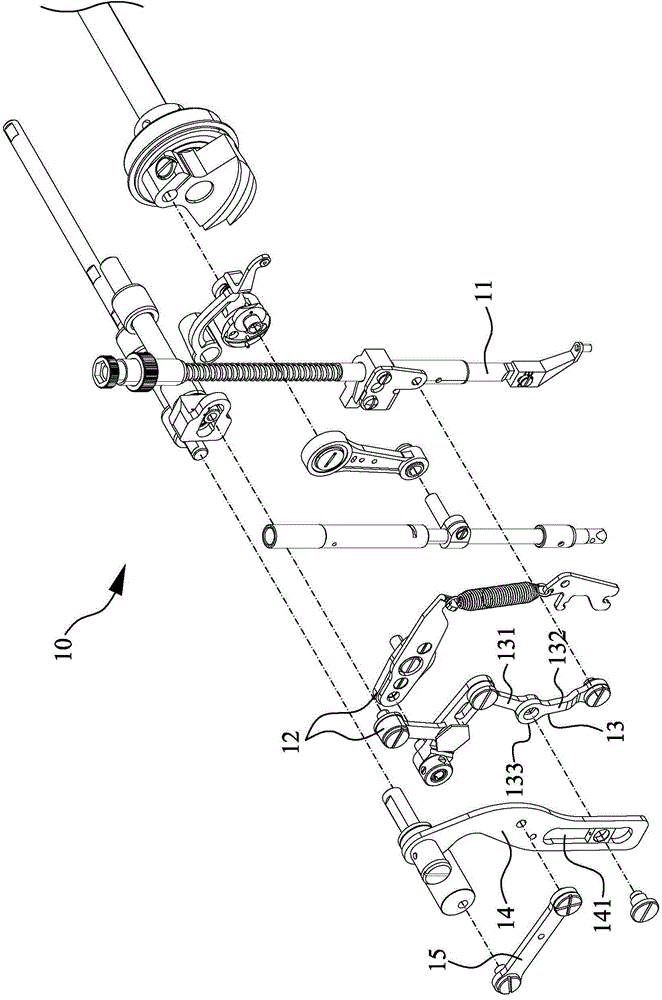

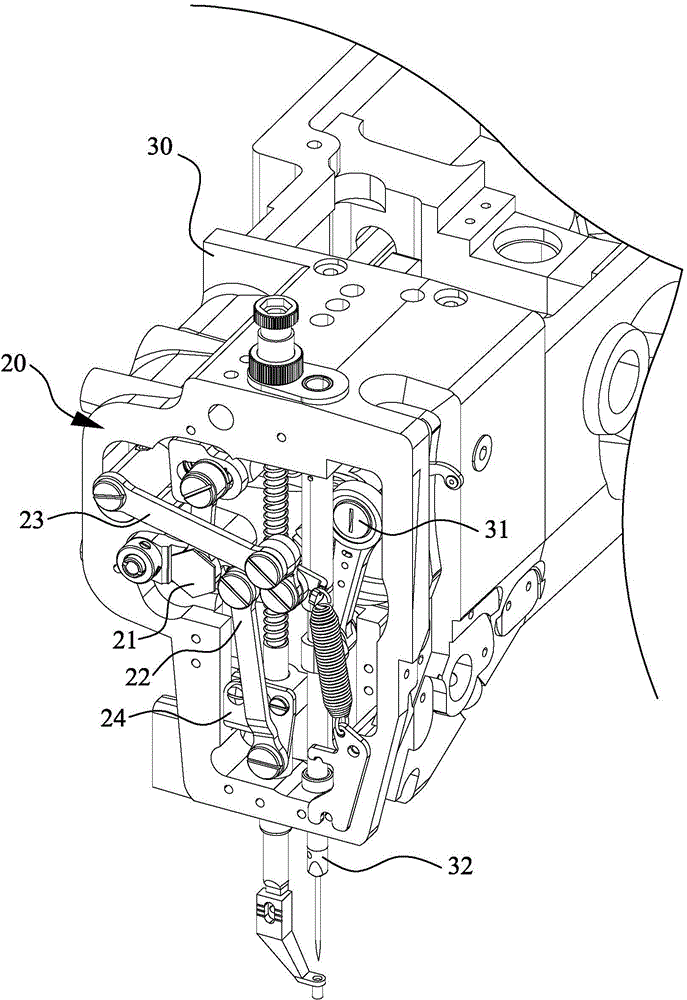

[0026] In order to further have a clearer and more detailed understanding and understanding of the structure, use and features of the present invention, a preferred embodiment is given, and the details are as follows in conjunction with the drawings:

[0027] First, see image 3 As shown, the inner presser foot device 20 of the present invention is mainly arranged at the front end of the headstock 30 of the sewing machine, and is installed in cooperation with the upper shaft (not shown) of the sewing machine, so that the upper shaft can simultaneously drive the needle bar 32 with a needle And the inner presser foot device 20 of the present invention.

[0028] As shown in the figure, the front end of the upper shaft is assembled with a crankshaft 31 and connected with a connecting rod to the needle bar 32, and the middle part of the upper shaft is fixedly provided with an eccentric cam (not shown) to drive The swing mechanism 21 of the movement amount of the inner presser foot...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap