A curved face rockfill dam structure and face rockfill dam to prevent extrusion damage

A technology of curved face slabs and rockfill dams, applied in dams, barrages, barrages, etc., can solve the problems of damage to the anti-seepage system and affect the safety performance of the dam body, so as to avoid extrusion damage and improve the working force. Status, the effect of improving work status

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

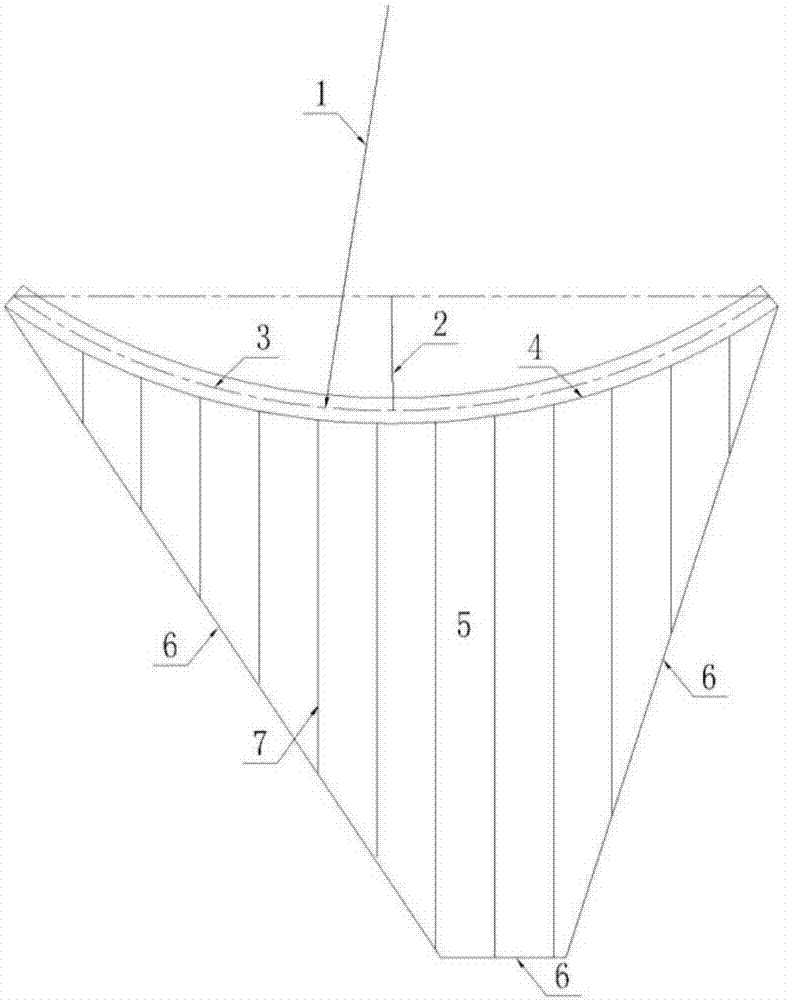

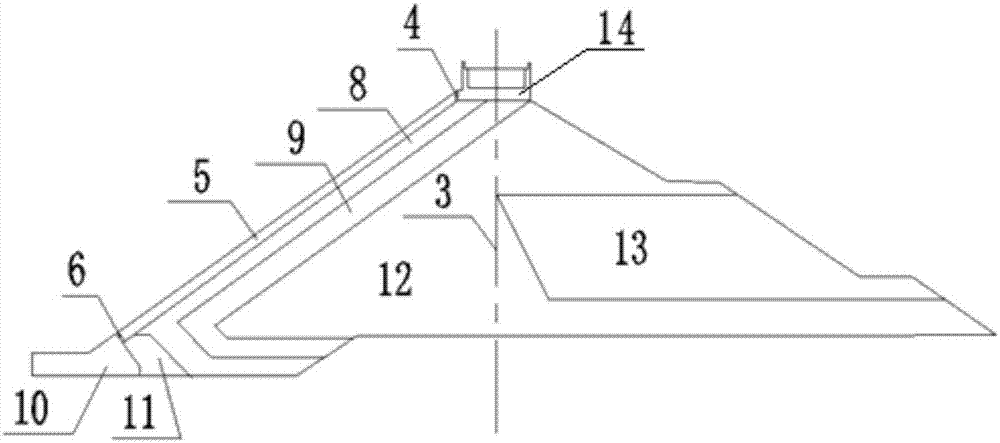

[0021] In order to overcome the defect that the anti-seepage system of the face rockfill dam is seriously damaged due to mutual extrusion damage of the existing face plates, the present invention provides such figure 1 and figure 2 The curved face rockfill dam structure for preventing extrusion damage includes a concrete face rockfill dam and a concrete face 5, and the concrete face rockfill dam and the concrete face are in an arc convex to the upstream on the horizontal plane.

[0022] The present invention offsets the extrusion stress of the panel through the arc-shaped face rockfill dam structure, reduces or avoids the axial displacement of the panel to the riverbed, improves the working stress state of the panel, reduces or avoids the situation of panel extrusion damage, and greatly improves the The working state of the panel.

Embodiment 2

[0024] On the basis of Example 1, such as figure 1 As shown, the top of the concrete panel 5 is connected with a wave wall 14, and a seam is provided between the bottom of the wave wall 14 and the top of the concrete panel 5, and the seam is the first peripheral seam 4, the first peripheral seam 4 The arc shape can make the stress distribution between the dam body and the concrete face plate 5 more uniform, and adjust and reduce the compressive stress at the joint between the dam body and the concrete face plate 5 .

[0025] Such as figure 1 As shown, there is a seam between the concrete panel 5 and the toe board 10, the seam is the second peripheral seam 6, and the second peripheral seam 6 is a straight line. The bending moment transmitted from the dam body to the toe plate 10 is reduced through the second peripheral seam 6, thereby reducing or even eliminating the vertical tensile stress on the upstream surface of the dam body, so that the stress distribution on the contact...

Embodiment 3

[0027] On the basis of Example 1, such as figure 1 As shown, the arc radius 1 and the rise height 2 of the arc-shaped face rockfill dam structure can be determined by combining the topographic and geological conditions, through finite element calculation, and assuming that the vertical joint 7 does not undergo extrusion deformation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com