Rotary positive displacement hydraulic device and hydraulic driving type petroleum production oil pump

A hydraulic device and rotary axis technology, applied in the field of hydraulic devices, can solve the problems of complex composition of stroke and stroke control system, high difficulty in manufacturing process, and insufficient work reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

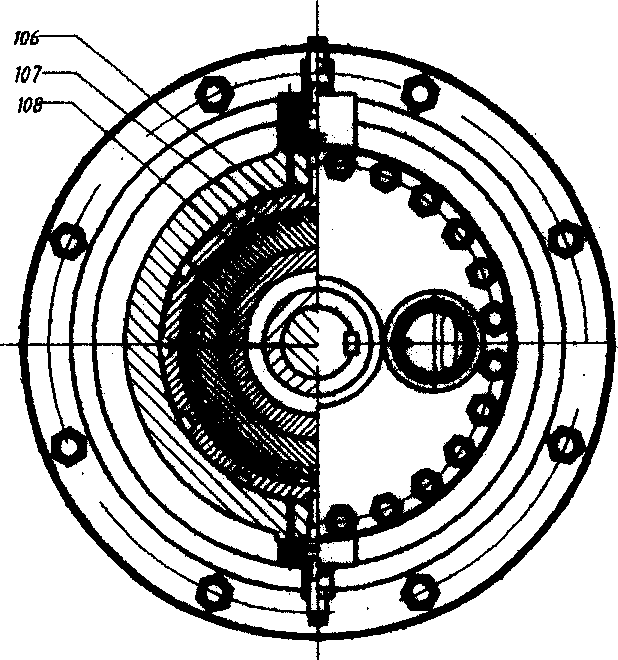

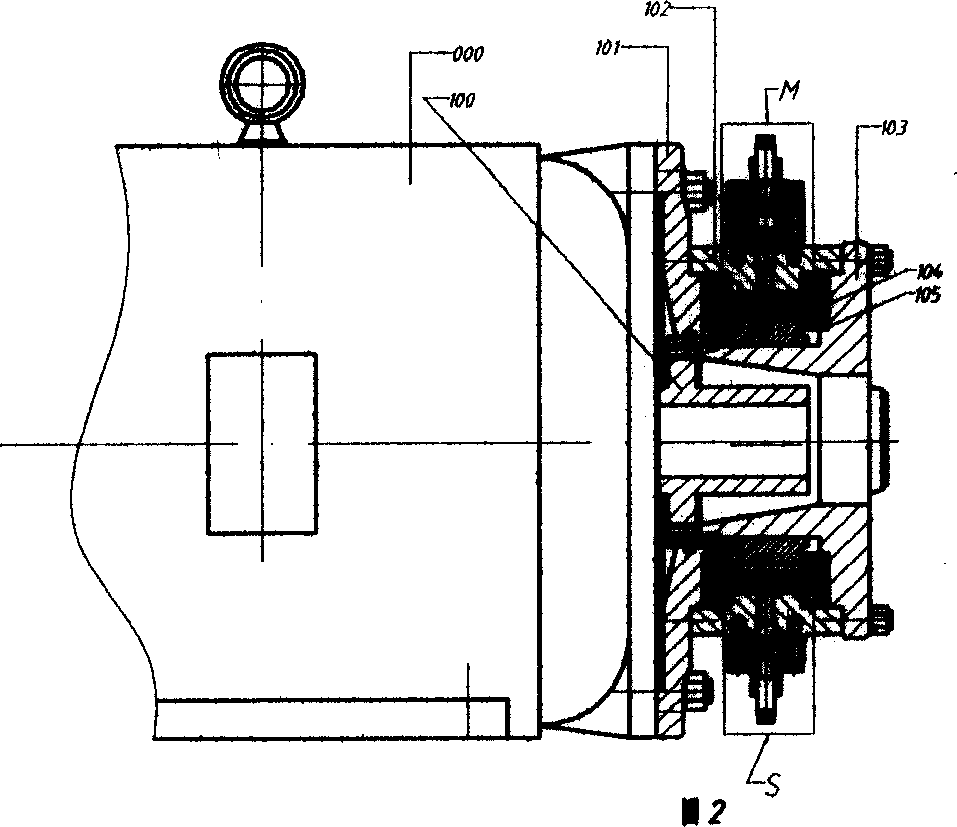

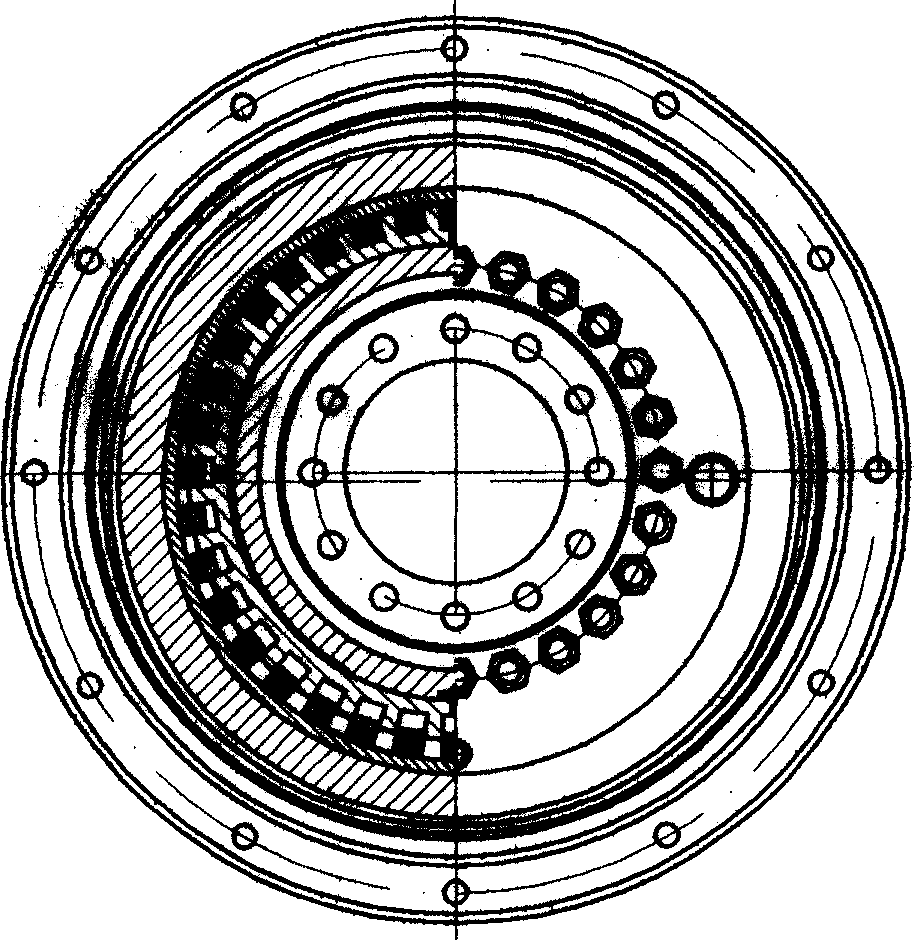

[0032] The specific structure of the embodiment of the slider type variable hydraulic pump is shown in the accompanying drawings figure 1 ,figure 2, Figure 5As shown in Fig. 8, Fig. 14 to Fig. 31: the slider 107 is sequentially assembled in the outer peripheral groove of the rotor main body component 108 to form the rotor component, and the other components are assembled and combined to form the stator component; wherein, the side disc body 104 and the flexible seal 105 It constitutes a floating side plate, and is composed of a piston 1091, a compression spring 1092, a spring seat 1093, an adjustment screw 1094, a lock nut 1095, and a cylinder body 1096 to form a control cylinder M, which is installed on the prefabricated assembly part of the outer peripheral body 102 through assembly bolts 1097 The balance cylinder S is composed of piston 1101, adjustment screw 1102, lock nut 1103, and cylinder body 1104, which is installed on the prefabricated assembly part of the outer per...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com