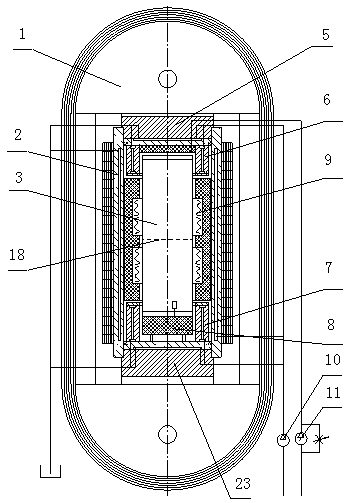

Hot isostatic pressing device suitable for ammonothermally producing gallium nitride monocrystal product

A gallium nitride single crystal, hot isostatic pressing technology, applied in the direction of single crystal growth, single crystal growth, crystal growth, etc. The effect of large size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

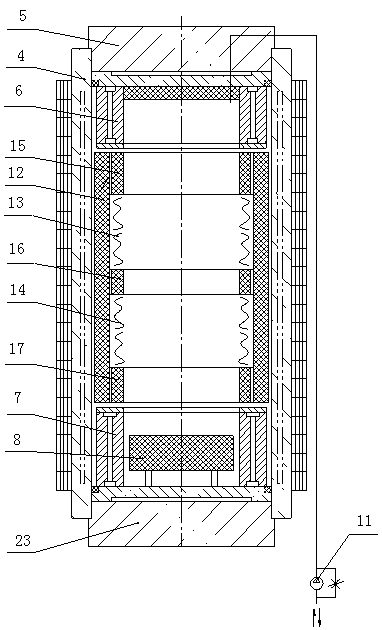

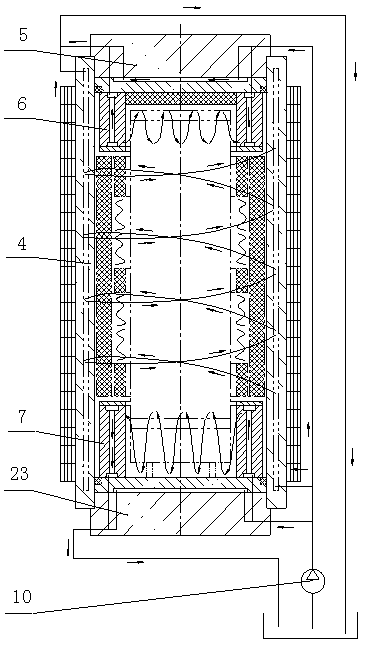

[0020] In order to further illustrate the preferred embodiment of the present invention, it will be described in detail below with accompanying drawings, so as to make the present invention easier to understand. However, the following descriptions are only used to explain the preferred embodiments of the present invention, and are not intended to limit the present invention in any form. Any modification or change made on the basis of the inventive spirit of the present invention, All should still belong to the category that the present invention intends to protect. It should also be noted that unless otherwise specified and limited, the term "setting" should be understood in a broad sense, and those skilled in the art can understand the specific meanings of the above terms in the present invention in specific situations.

[0021] Hot isostatic pressing technology is a kind of process in a closed ultra-high pressure container, using nitrogen or argon as the pressure transmissio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com