Self pre-tightening force rotating shaft component

A technology of preload and components, applied to building components, vehicle components, roofs, etc., can solve the problems of complex assembly, poor noise reduction effect of energy storage mechanism, etc., and achieve the effect of convenient use and assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to make the technical means, creative features, objectives and effects achieved by the present invention easy to understand, the present invention will be further elaborated below.

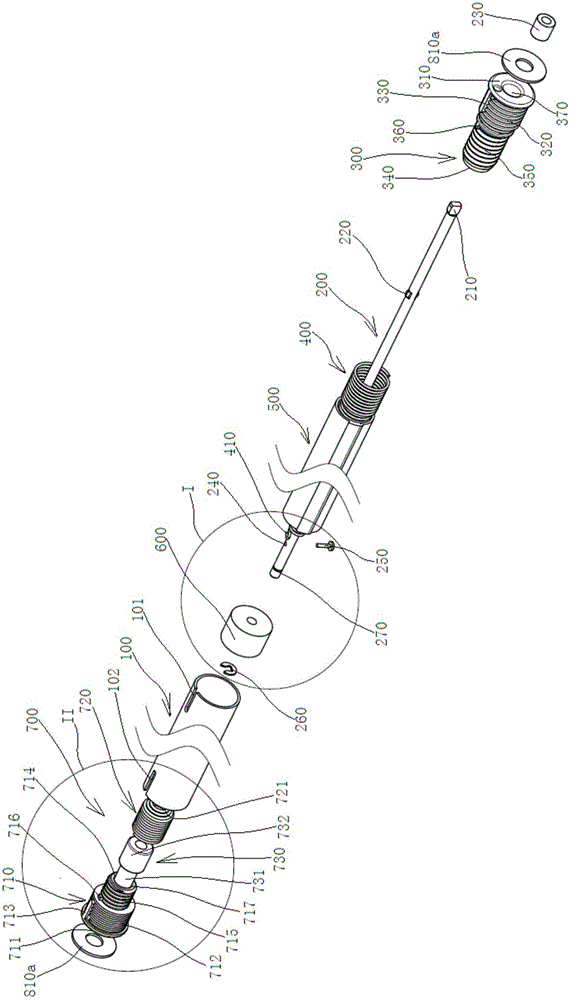

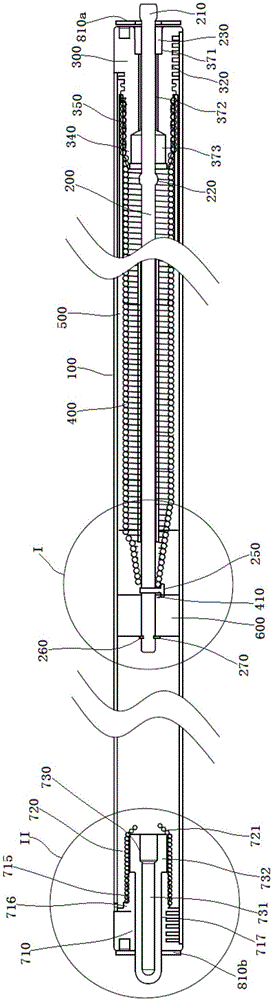

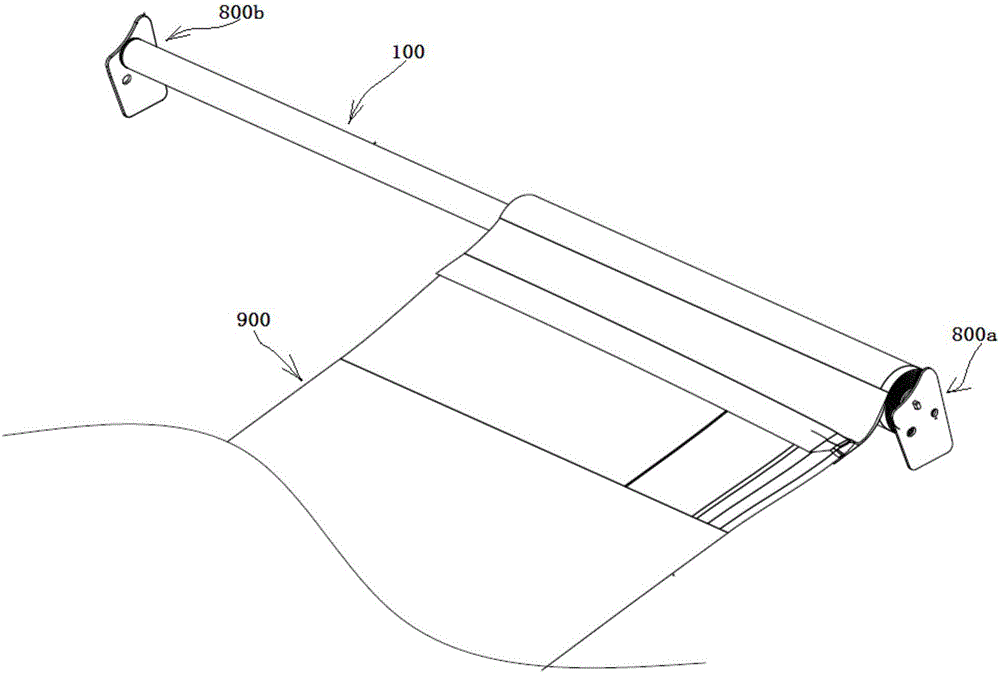

[0030] see Figure 1 to Figure 3 A self-pretensioning rotating shaft assembly shown includes a bushing 100 , a torsion spring assembly center shaft 200 , a first fixing block 300 , a torsion spring 400 , a buffer sleeve 500 and an elastic buffer washer 600 .

[0031] The casing 100 in this embodiment is an aluminum tube, and an axial notch 101 , 102 is formed on the outer surface of both ends of the casing 100 . The central shaft 200 of the torsion spring assembly is arranged in the casing 100, and the central shaft 200 of the torsion spring assembly is preferably a steel shaft.

[0032] A flattened head 210 is processed at the front end of the central axis 200 of the torsion spring assembly, a pair of ear portions 220 are arranged near the front end, and a collar 230 is set betwe...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap