Crawling ladder for maintenance

A technology for climbing ladders and longitudinal beams is applied in the field of climbing devices for maintenance of large-scale equipment, which can solve the problems of safety accidents and loose safety awareness, and achieve the effect of reducing the possibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to enable those skilled in the art to better understand the technical solution of the present invention, the solution will be further described in detail below in conjunction with specific embodiments.

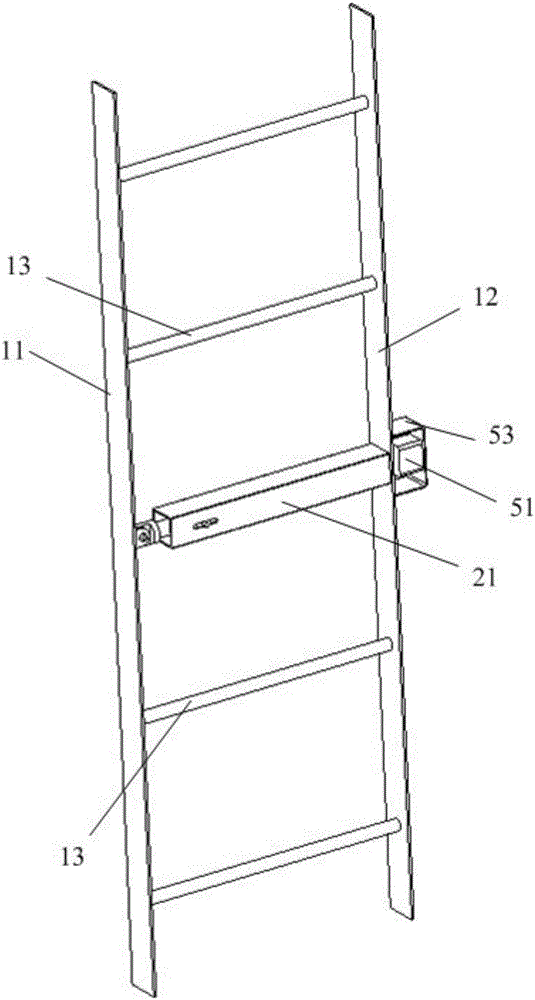

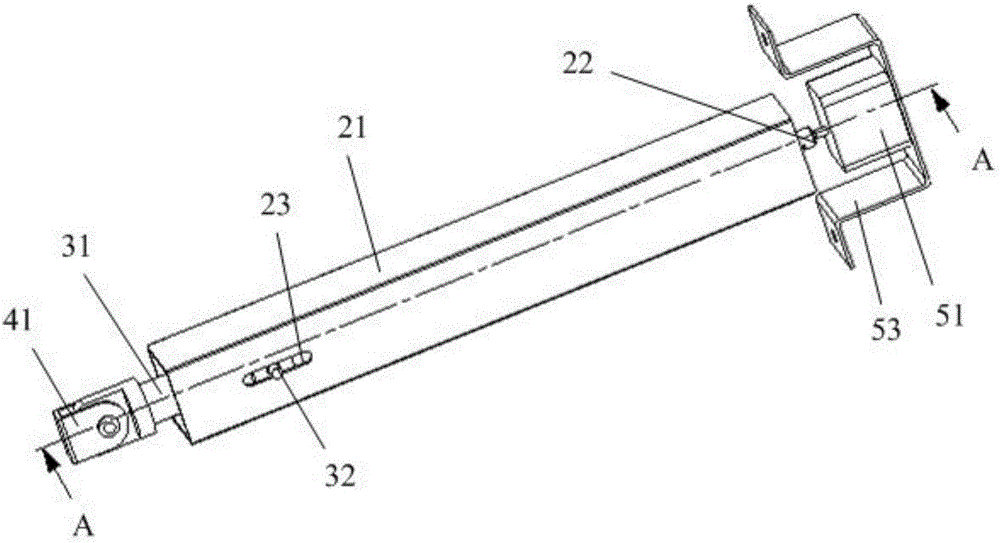

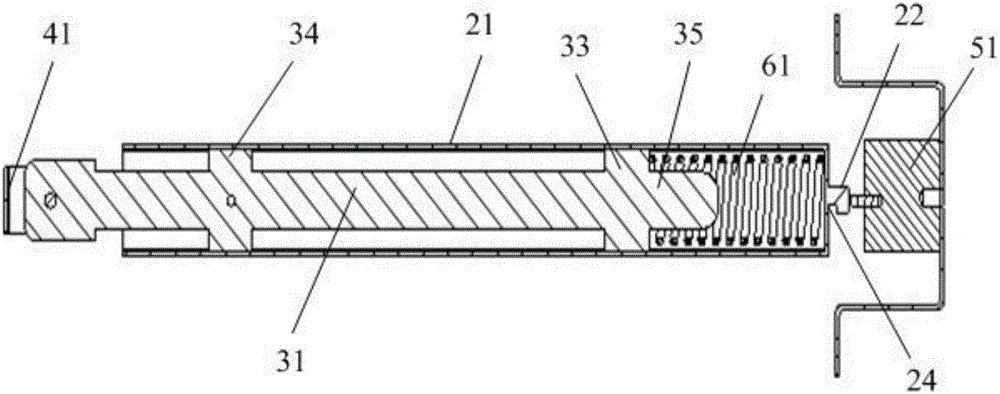

[0032] Such as Figure 1 to Figure 6 As shown, the embodiment of the present invention provides a maintenance ladder, which includes a first longitudinal beam 11, a second longitudinal beam 12, and a plurality of cross beams 13 arranged in parallel between the first longitudinal beam 11 and the second longitudinal beam 12, At least one crossbeam 13 is a safety protection beam, and the safety protection beam includes a safety crossbar 31, a crossbar cover 21, a bracket 41 and a sensor 51 sleeved on the safety crossbar 31; one end of the bracket 41 is connected with the first longitudinal beam 11; The first end 36 of cross bar 31 is rotationally connected with the other end of support 41 by rotating shaft 42; An elastic telescopic member is arranged between the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com