Image processing method for automatic steel plate bending angle measurement robot based on monocular vision

An image processing and automatic measurement technology, applied in image data processing, image analysis, graphics and image conversion, etc., to reduce interference edge points, reduce false edge points, and reduce the amount of calculation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

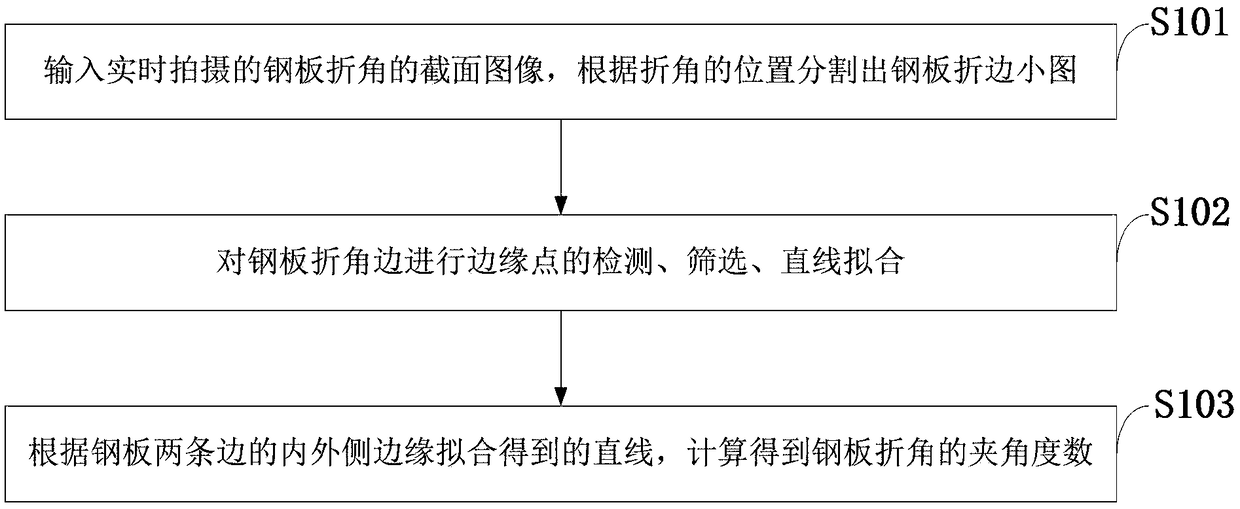

[0033] The image processing method of the robot for automatically measuring steel plate folding angle based on monocular vision in the embodiment of the present invention includes the following steps:

[0034] Step 1, input the real-time cross-sectional image I of the steel plate kink angle to be detected;

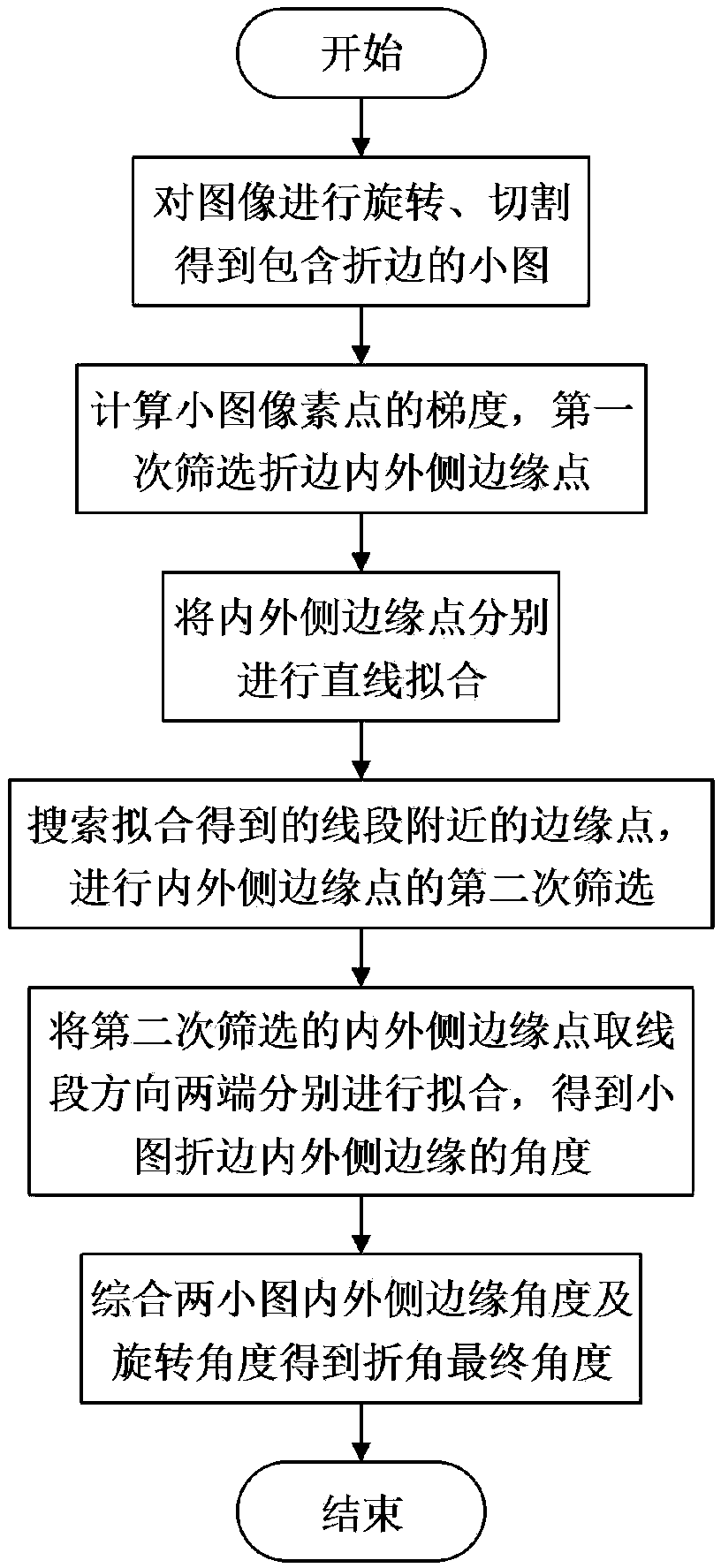

[0035] Step 2: Rotate and cut image I to obtain a small image containing folded edges.

[0036]In the actual steel plate knuckle image I, the knuckle opening is upward, the knuckle angle is about 90 degrees, and the angle between the left and right folds and the vertical direction is about 45 degrees. side is L 1 , the upper edge on the left side is L 2 ;

[0037] (2.1) Rotate the image α=45 degrees clockwise to obtain the image I', and calculate the vertex V' after the vertex V is rotated;

[0038] (2.2) Extend the vertex V' upward to take the long bar graph S 2 Includes hem L 2 ', extend the vertex V' to the right and take the small bar graph S 1 , the graph S 1 ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap