Thermo-sensitive embossing flat-plate hand mold

A sensitive embossing and hand mold technology, which is applied in the field of heat sensitive embossed flat hand molds, can solve the problems of poor anti-skid effect of embossed gloves, uneven wall thickness of hand molds, unfavorable embossing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

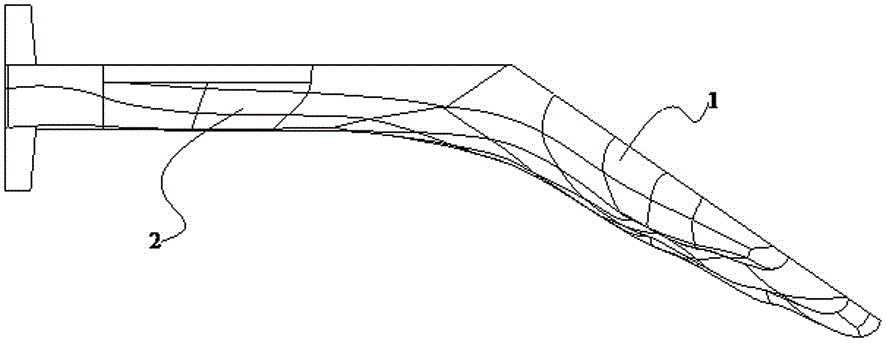

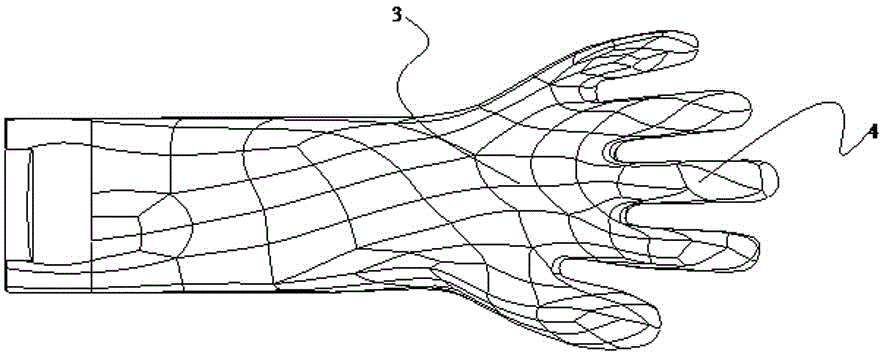

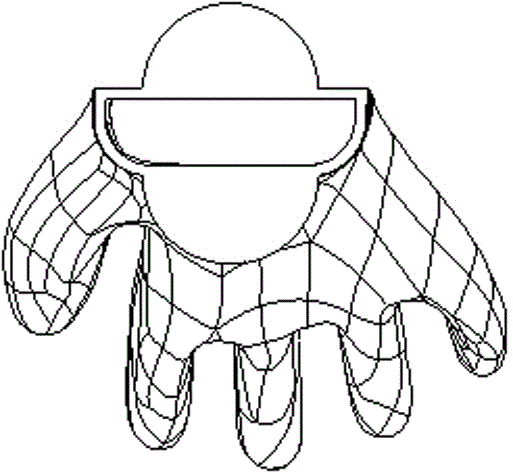

[0017] refer to Figure 1 to Figure 4 , a heat-sensitive embossed flat hand model, the angle of the hand model can be changed, it includes the palm 1, the neck of the hand 2, the back of the hand 3, and the fingers 4; the front of the palm 1 and the fingers 4 are on the same plane, and the back of the fingers 4 is Pointed; the two ends of the boss at the end of the neck 2 have drill holes; by generating pressure on the back of the hand 3, the pattern on the template will be pressed onto the palm and the front of the fingers.

[0018] Preferably, the hand mold has a uniform wall thickness.

[0019] More preferably, the 1st surface of the palm and the 2nd surface of the neck form an angle of 145 degrees.

[0020] As the most preferred method of the present invention, the palm 1 of the hand mold is in a horizontal plane during work, which is convenient for dipping and embossing.

[0021] In order to facilitate embossing, the present invention increases the embossing area and st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com