Three-dimensional vibration isolation support with adjustable vertical early-stage rigidity

A shock-isolation support and vertical shock-isolation technology, applied in the direction of shock-proof, building components, building types, etc., can solve the problems of reducing the cost of shock-isolation, shortening the effective working length of the spring, not being able to stretch, energy-consuming and shock-absorbing, etc., to achieve The effect of buffering tensile and compressive shocks, reducing the cost of wind and shock resistance, and reducing the risk of overturning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

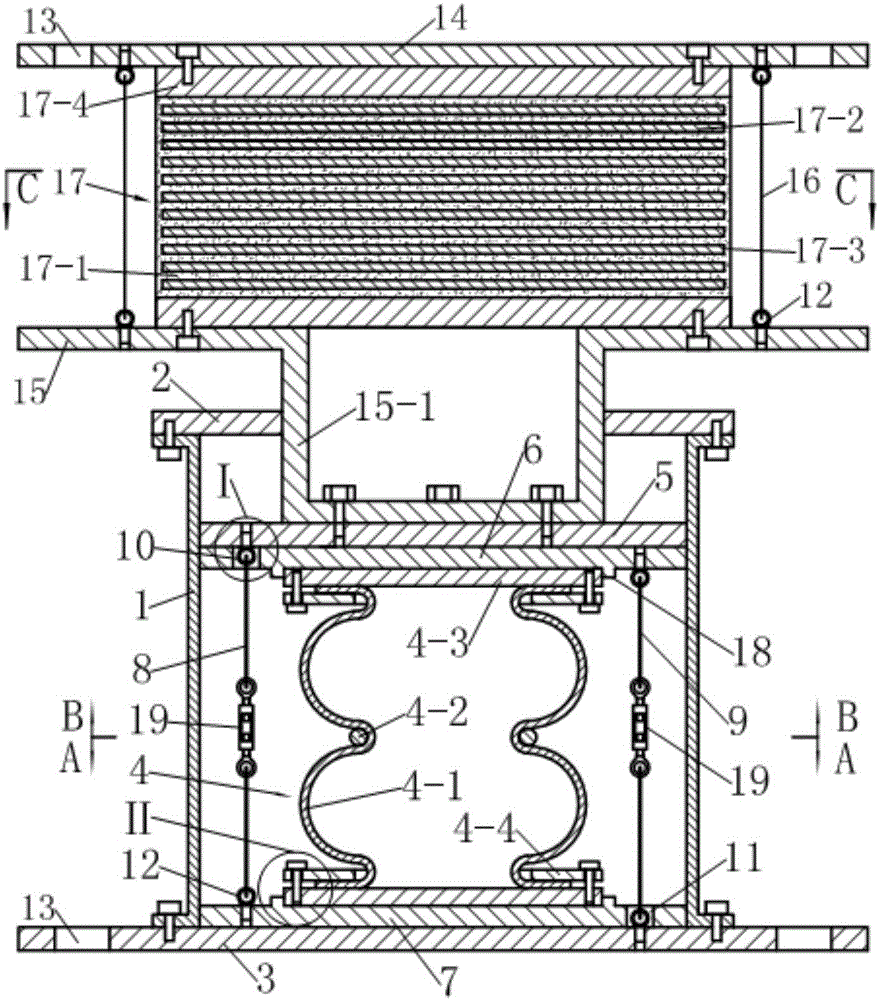

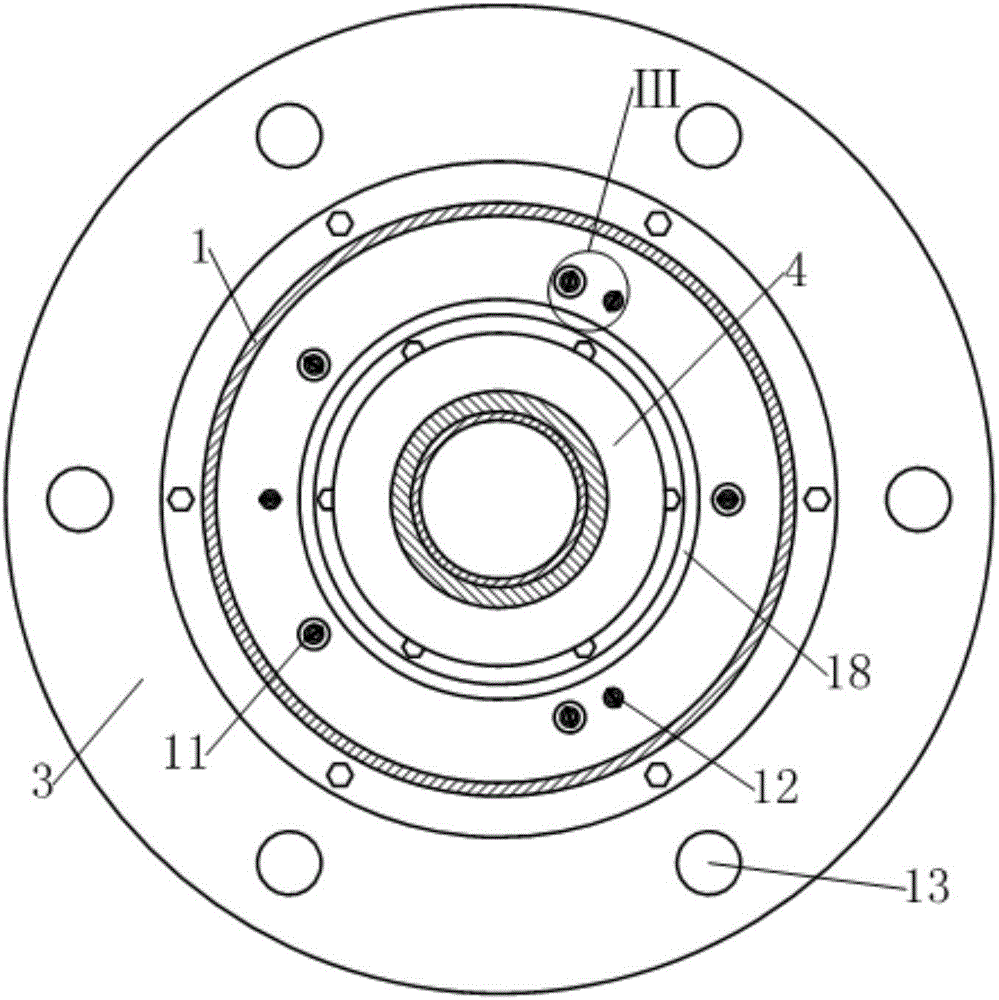

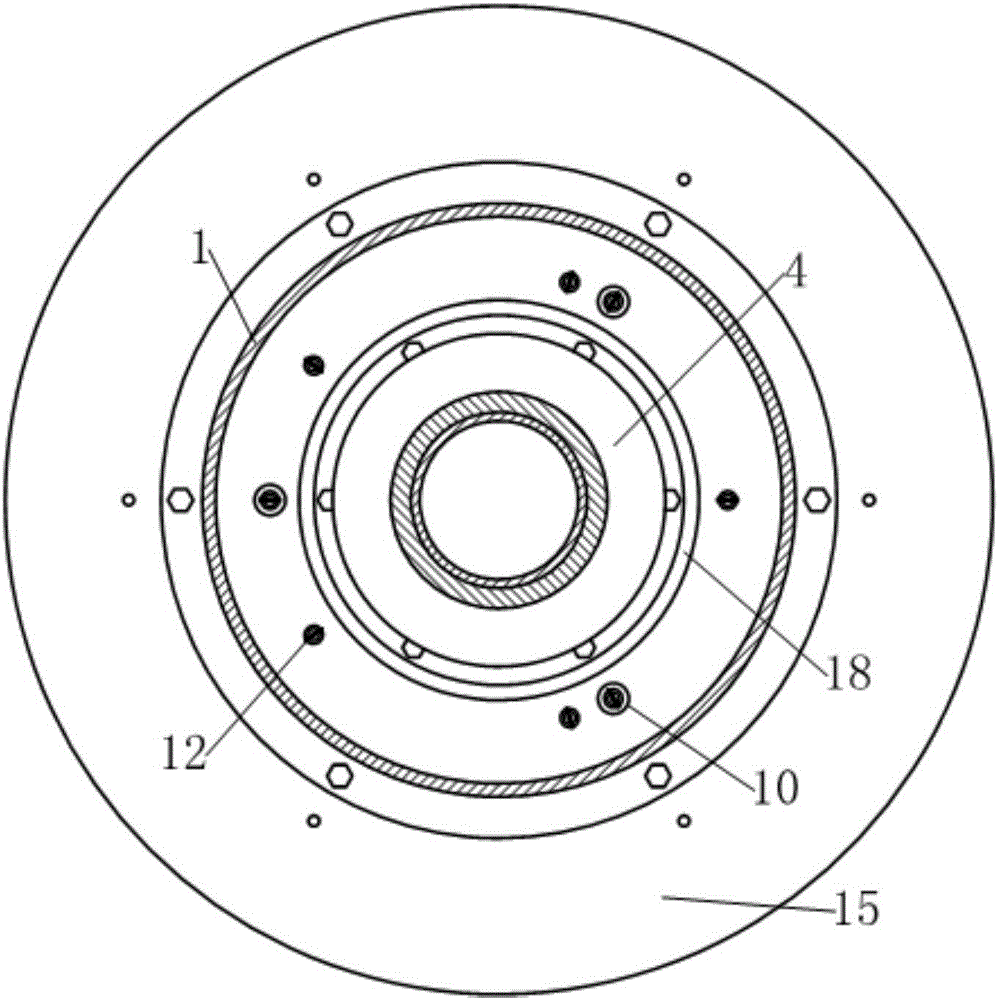

[0036] see figure 1 , the three-dimensional seismic isolation bearing in this example is composed of laminated rubber isolation bearings and vertical isolation bearings connected in series up and down.

[0037] see figure 1 with Figure 4 , the laminated rubber shock-isolation bearing includes an upper connecting plate 14, a lower connecting plate 15, a laminated rubber pad 17 clamped between the upper and lower connecting plates and six tensile steel cables 16; wherein, the upper Both the connecting plate 14 and the lower connecting plate 15 are disc-shaped, and the edge of the upper connecting plate 14 is provided with mounting holes 13; the main body of the laminated rubber pad 17 is alternately composed of a layer of rubber 17-1 and a layer of steel plate 17-2 After lamination, it is molded and vulcanized, and a rubber protective layer 17-3 is naturally formed around it during the process of molded vulcanization. The upper and lower end surfaces of the main body of th...

example 2

[0051] This example has the following differences from Example 1:

[0052] see Figure 8-10 , the first group of preloaded steel cables 8 and the second group of preloaded steel cables 9 are composed of three preloaded steel cables. The number of said rigging turnbuckles 19 is reduced to six, and they are connected in series in the middle of each preloaded steel cable respectively.

[0053] The above-mentioned implementation method of this example is the same as Example 1.

example 3

[0055] see Figures 11 to 13 , The difference between this example and Example 2 is that the first group of preloaded steel cables 8 and the second group of preloaded steel cables 9 are composed of five preloaded steel cables. The number of said rigging turnbuckles 19 is reduced to ten, and they are respectively connected in series at the middle part of each preloaded steel cable.

[0056] Other implementations of this example other than the above are the same as Example 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com