Continuous rolling planetary mill

A planetary rolling mill and drive motor technology, applied in metal rolling, metal rolling, manufacturing tools, etc., can solve the problems of low rolling efficiency, feeding, rolling, and receiving intermittent, feeding and receiving, etc., to achieve The effect of reducing the turnover time of receiving materials, prolonging the service life and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

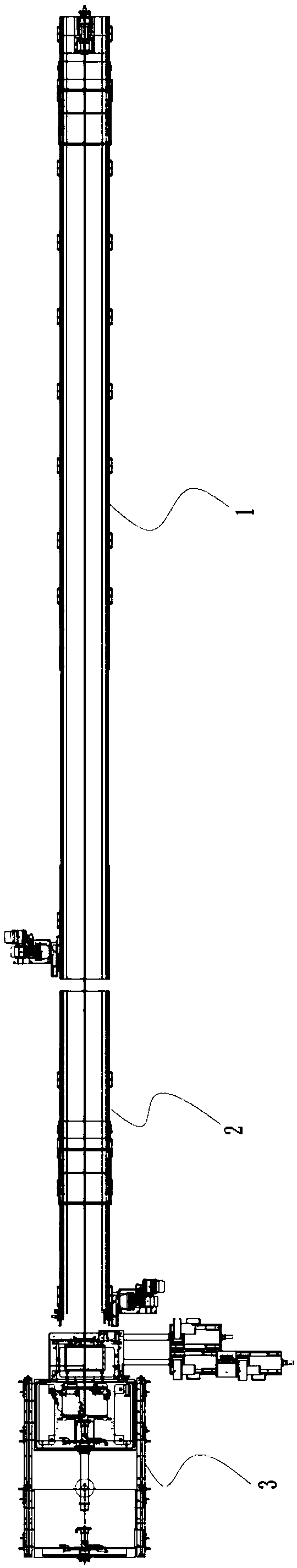

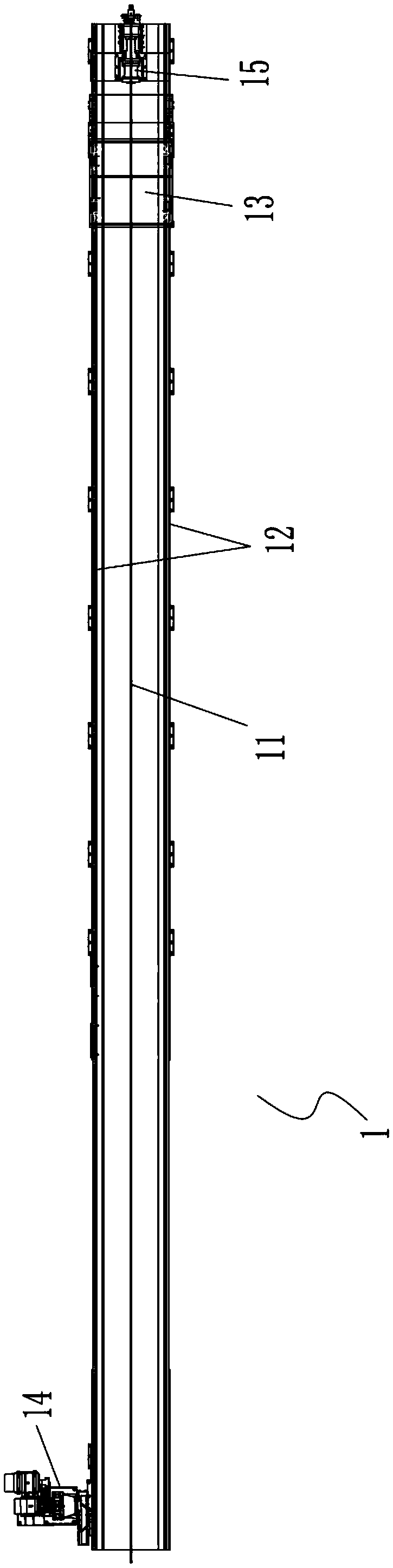

[0032] see figure 1 , The present invention provides a continuous rolling planetary rolling mill, which includes a first feeding mechanism 1, a second feeding mechanism 2 and a rolling mechanism 3 arranged sequentially from one side to the other according to the sequence of stations. The first feeding mechanism 1 pushes the received material to be rolled to the second feeding mechanism 2, and returns to its initial station to continue receiving the next material to be rolled after the material is advanced; The second feeding mechanism 2 advances the material received from the first feeding mechanism 1 to the rolling mechanism 3, and returns to its initial station after completing the material advancement to continue to accept the materials advanced by the first feeding mechanism 1. The next material to be rolled.

[0033] Thus, through the cooperative work of the two feeding mechanisms, the first feeding mechanism 1 can continue to load and feed materials while the second fee...

Embodiment 2

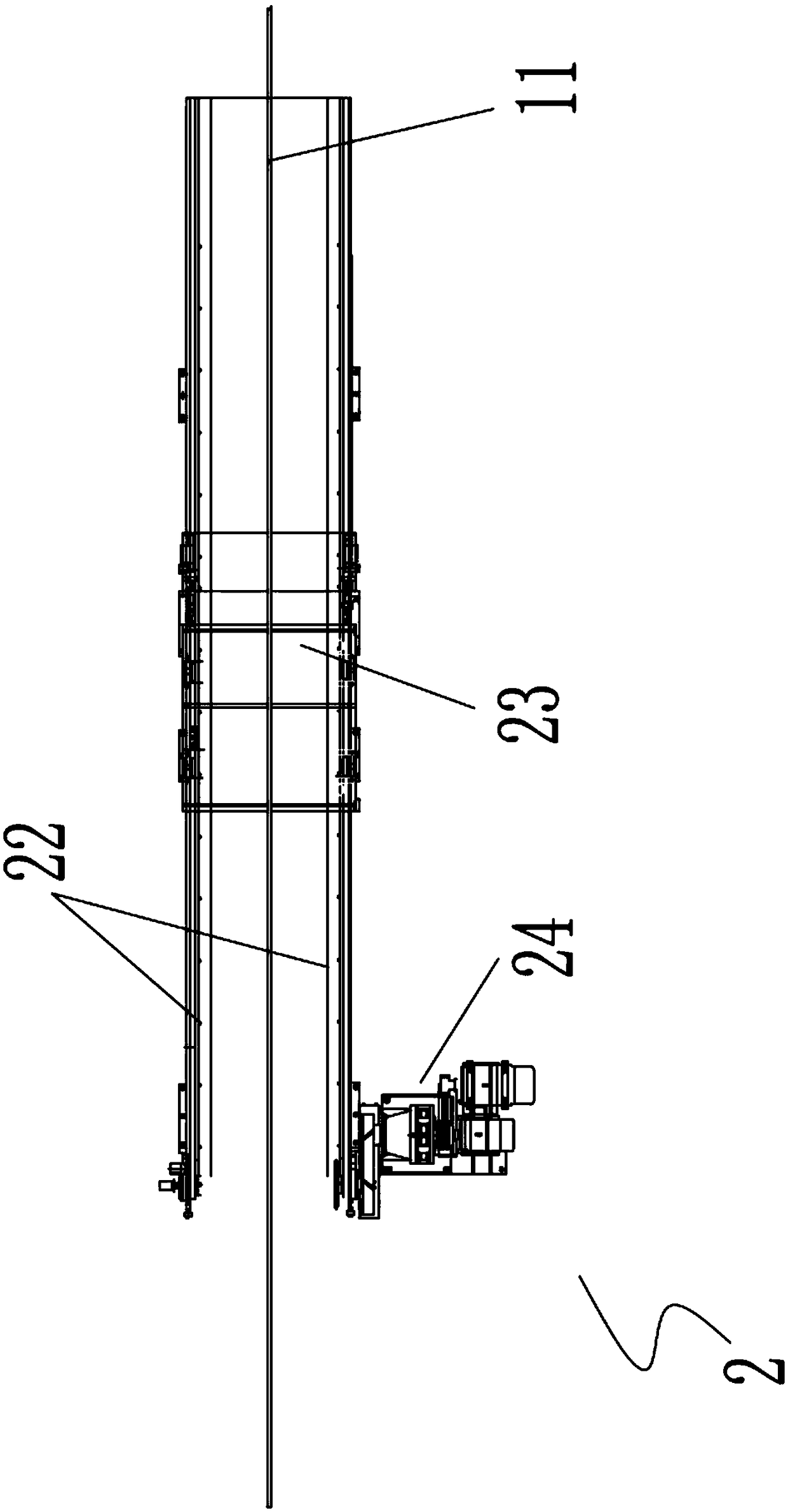

[0045] The structure of this embodiment is basically the same as that of Embodiment 1. The difference is that in this embodiment, in order to enhance the stability of material transportation between the two feeding mechanisms and further improve the continuity and efficiency of material transportation, please refer to Figure 4 , The second feeding mechanism 2 further includes a rotary chuck 25;

[0046] In order to ensure better and faster conveying of the slab and avoid affecting the feeding efficiency due to misalignment, as a more optimal technical solution, the axis of the rotary chuck 25 of the second feeding mechanism 2, the axis of the first feeding The axis of the rotary chuck 25 of the feeding mechanism 1 and the axis of the core rod 11 are collinear.

[0047] Then in the feeding process, the core rod 11 is first clamped by the rotary chuck 25 of the second feeding mechanism 2, when the feeding trolley 13 of the first feeding mechanism 1 clamps the cast slab and push...

Embodiment 3

[0049] The structure of this embodiment is basically the same as that of Embodiment 2, the difference is that in this embodiment, in order to further improve feeding efficiency and rolling efficiency, please refer to Figure 5 and Figure 6 , as a more optimal technical solution, the continuous rolling planetary rolling mill of the present invention also includes a storage rack 4 and a conveying roller table 5 . The storage rack 4 transports the material to be rolled stored thereon to the conveying roller table 5 , and is output to the first feeding mechanism 1 by the conveying roller table 5 .

[0050] In this embodiment, since the storage rack 4 has the same structure as the existing storage rack for storing and turning over the hollow cast slab, and the conveying roller table 5 is the same as the existing conveying roller table for conveying the hollow cast billet to the feeding mechanism , so it will not be repeated here.

[0051] Then in the feeding process, the casting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com