A multi-directional clamping steel pipe cutting delivery device

A delivery device, clamping technology, applied in the field of multi-directional clamping steel pipe cutting delivery device, can solve the problem that the steel pipe cannot be delivered forward at a fixed distance, and achieve the effect of convenient rotation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

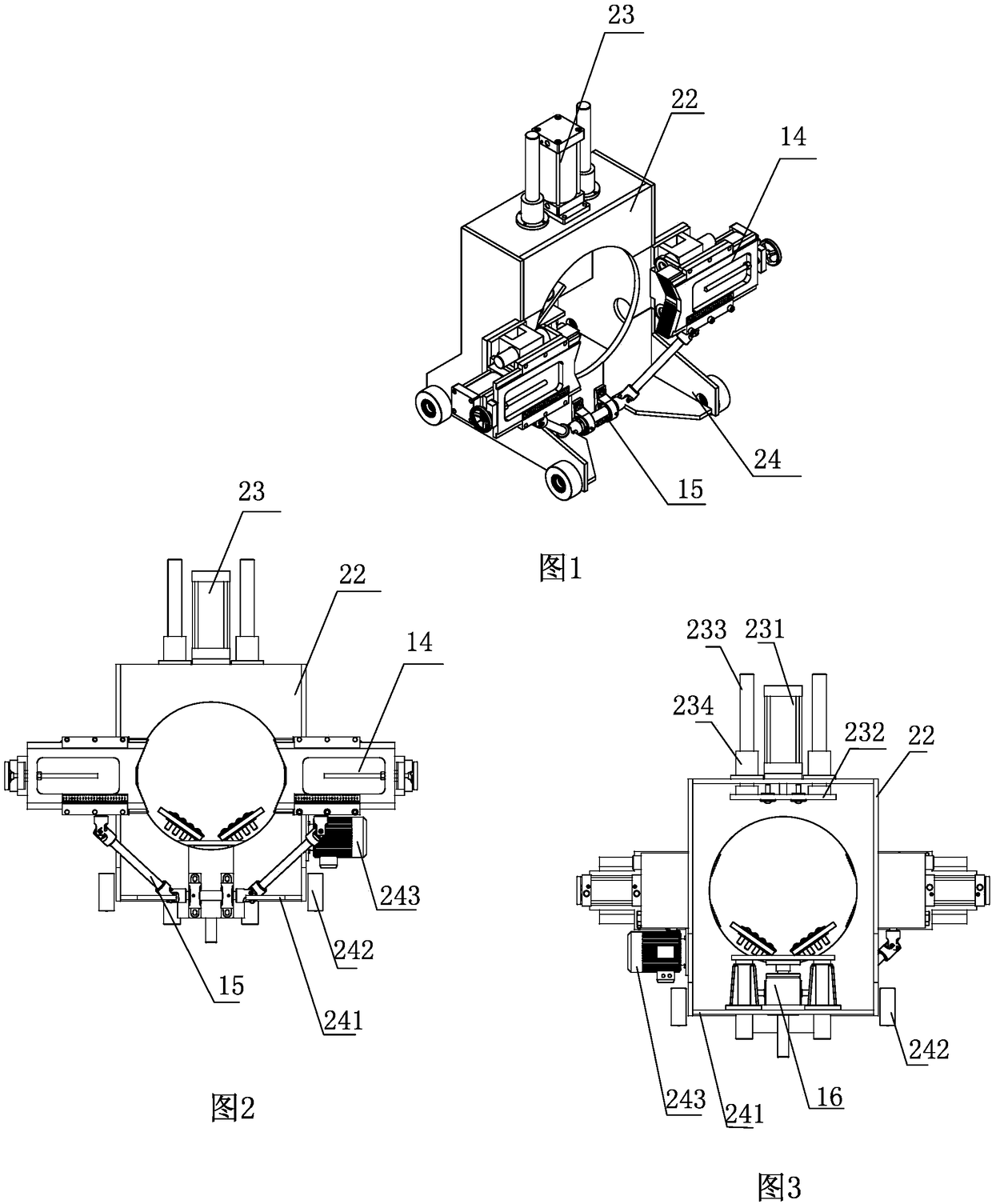

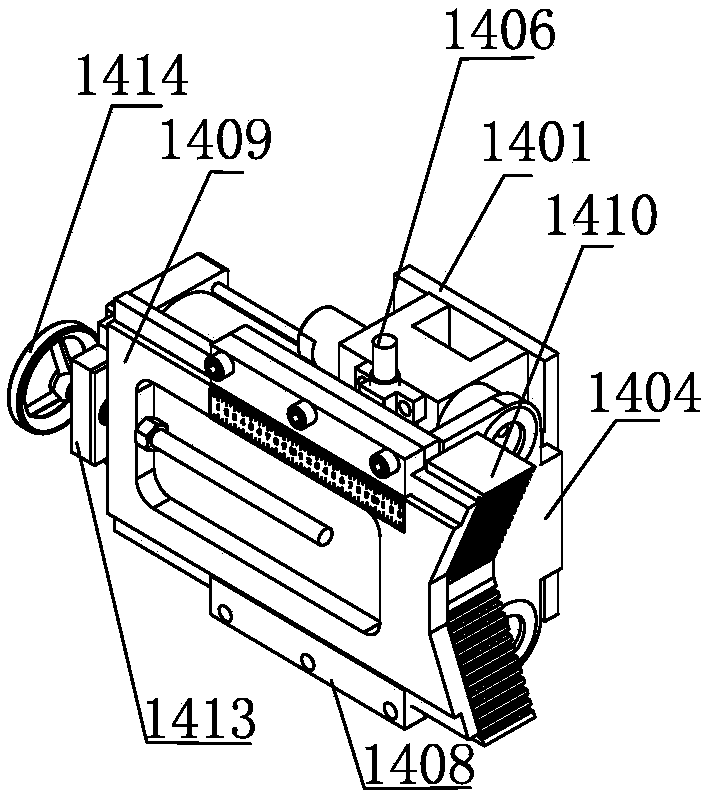

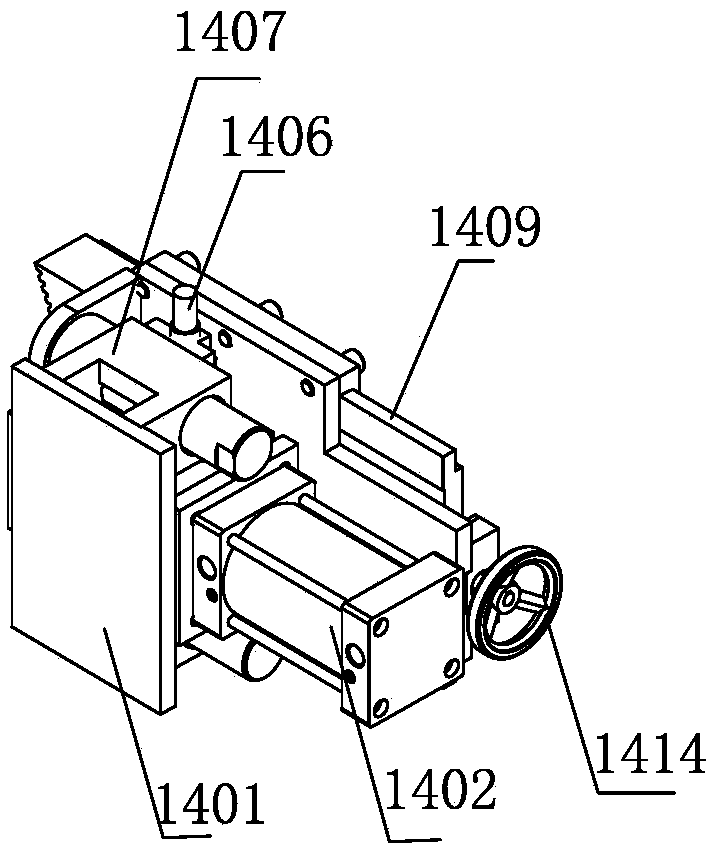

[0035] Such as Figures 1 to 12 As shown, a multi-directional clamping steel pipe cutting delivery device is installed behind the plasma cutting machine, and is used to deliver the steel pipe forward at a fixed distance during the steel pipe cutting process, so as to realize the fixed distance cutting of the steel pipe. A multi-directional clamping type steel pipe cutting delivery device includes a fixed-length delivery guide rail 21, a fixed-length clamping installation frame 22, a clamping mechanism 14, a two-way synchronous clamping drive connection mechanism 15, a fixed-length clamping pressing mechanism 23, a support Lifting mechanism 16, clamping mobile disk mechanism 24, chassis 5 and control system. The fixed length clamping installation frame 22 is mainly used for fixing and installing other devices of the present invention, the fixed length clamping installation frame 22 adopts a rectangular frame structure, and the middle longitudinal direction of the fixed length c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com