Double-station laser cutting workbench

A laser cutting and workbench technology, applied in laser welding equipment, manufacturing tools, metal processing equipment, etc., can solve the problems of large but not strong manufacturing, the gap between the quality and efficiency of informatization, etc., to ensure flexibility and sensitivity, with The effect of self-displacement repair ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

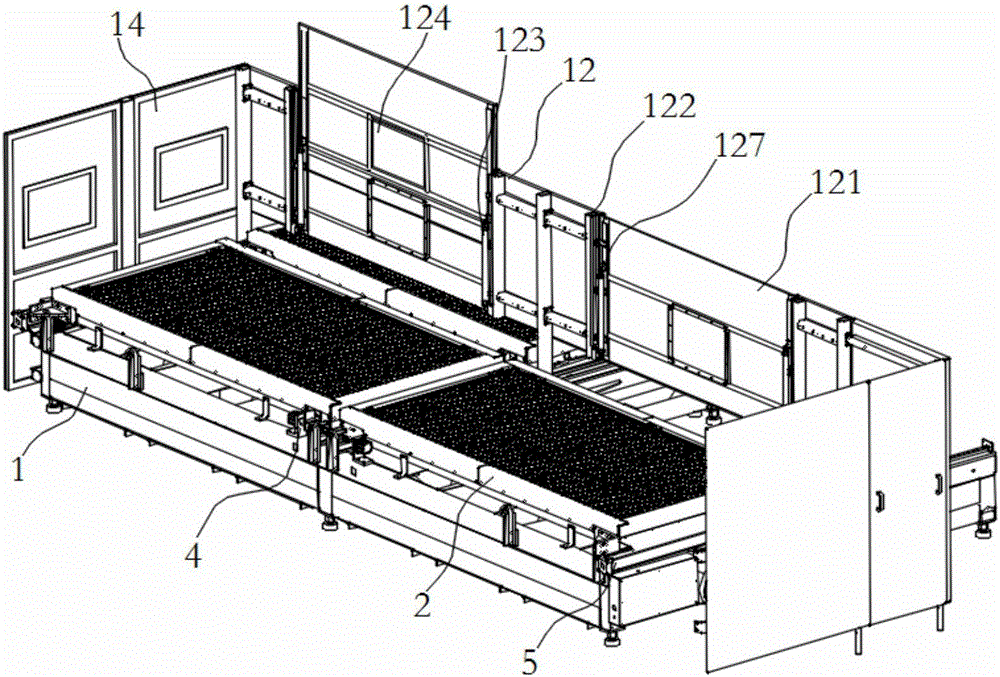

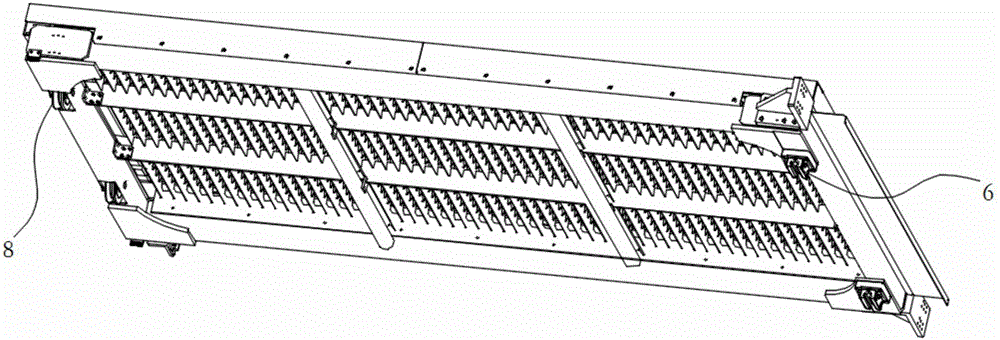

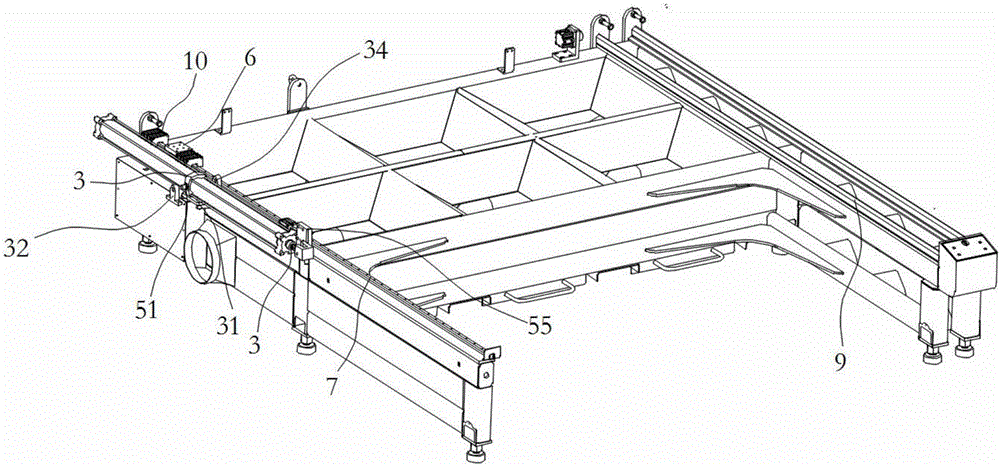

[0033] Embodiment 1: A double-station laser cutting workbench, including a base 1, a work platform 2, a positioning mechanism 4, a drive cylinder 5 and a safety door mechanism 12, and at least two slides are fixed on the bottom of one end of the work platform 2. Block 6, a V-shaped guide wheel 8 is installed at the bottom of the other end, linear guide rails 7 and V-shaped guide rails 9 are respectively fixed on the two ends of the upper surface of the base 1, and the linear guide rail 7 of the base 1 is embedded in the work platform 2 In the slider 6, the V-shaped guide rail 9 of the base 1 is in contact with the V-shaped guide wheel 8 of the work platform 2;

[0034] A central mounting base 3 is fixed on the outer side of one end of the slide block on the working platform 2. This central mounting base 3 includes a base plate 31 and a left support plate 32 and a right support plate 33 respectively located at both ends of the base plate 31. Both sides of the middle part have ro...

Embodiment 2

[0040] Embodiment 2: A double-station laser cutting workbench, including a base 1, a work platform 2, a positioning mechanism 4, a drive cylinder 5 and a safety door mechanism 12, and at least two slides are fixed on the bottom of one end of the work platform 2. Block 6, a V-shaped guide wheel 8 is installed at the bottom of the other end, linear guide rails 7 and V-shaped guide rails 9 are respectively fixed on the two ends of the upper surface of the base 1, and the linear guide rail 7 of the base 1 is embedded in the work platform 2 In the slider 6, the V-shaped guide rail 9 of the base 1 is in contact with the V-shaped guide wheel 8 of the work platform 2;

[0041] A central mounting base 3 is fixed on the outer side of one end of the slide block on the working platform 2. This central mounting base 3 includes a base plate 31 and a left support plate 32 and a right support plate 33 respectively located at both ends of the base plate 31. Both sides of the middle part have ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com