Mold releasing mechanism

A technology of demolding mechanism and sliding seat, which is applied to household components, household appliances, other household appliances, etc., can solve problems such as product sticking to the top block.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

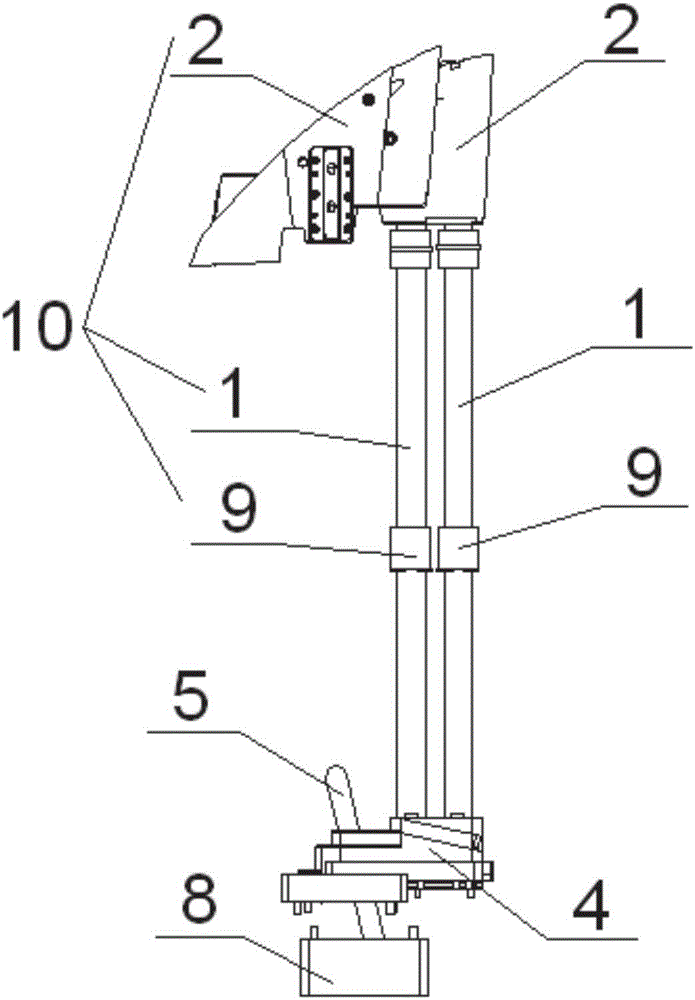

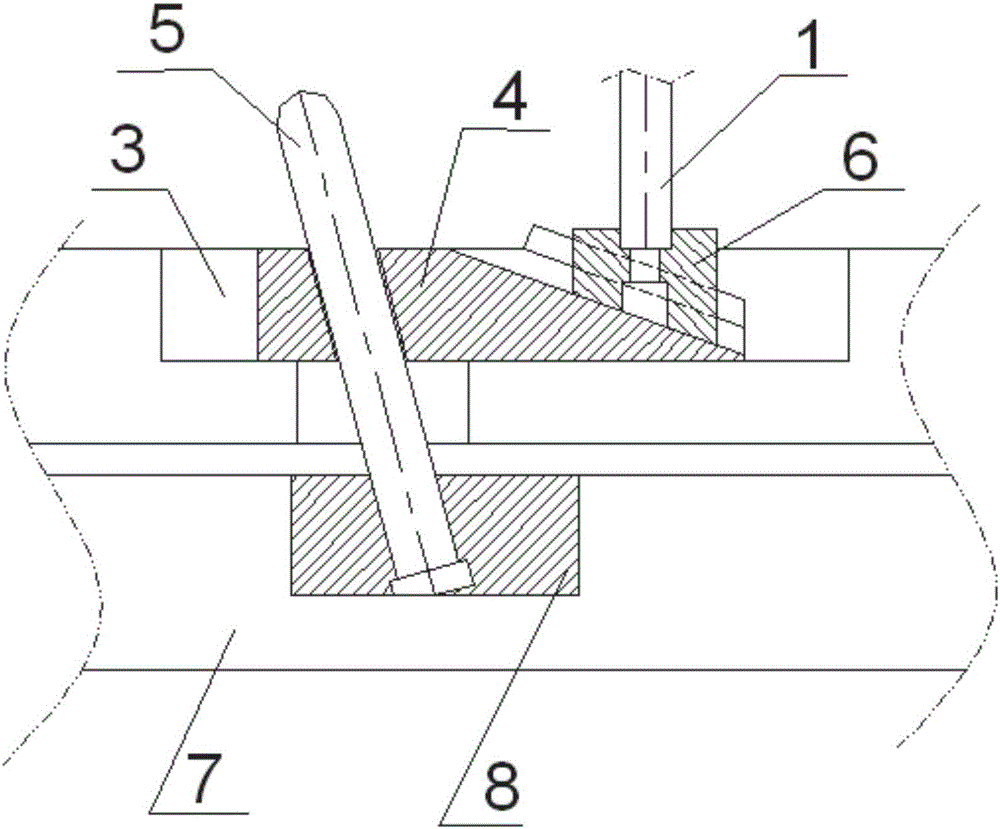

[0023] Example: such as figure 1 As shown, this embodiment provides a specific embodiment of a demoulding mechanism, and the demoulding mechanism is suitable for being installed in a mold for molding an automobile bumper.

[0024] refer to figure 1 and figure 2 , the demoulding mechanism includes a ejector rod device 10 for ejecting products, the ejector rod device 10 includes a straight ejector rod 1 connected to a ejector block 2 arranged at one end of the straight ejector rod 1 . We define that the end where the top block 2 is located is the upper side, then the top block 2 is connected to the upper end of the straight ejector rod 1 for ejecting the product. The ejector rod device 10 also includes a ejector rod fixing seat 6 and a ejector rod guide sleeve 9 arranged at the lower end of the straight ejector rod 1 . Wherein, the ejector rod holder 6 is used to fix the straight ejector rod 1, and the ejector rod guide sleeve 9 plays a guiding role for the straight ejector ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com