Box-type pressure-superposed water supply equipment

A technology of superimposed water supply and equipment, applied in water supply devices, water conservation, water supply main pipelines, etc., can solve problems such as waste of drinking water, inability to effectively control water pressure in real time, waste of tap water pressure energy, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Below, the substantive features and advantages of the present invention will be further described in conjunction with examples, but the present invention is not limited to the listed examples.

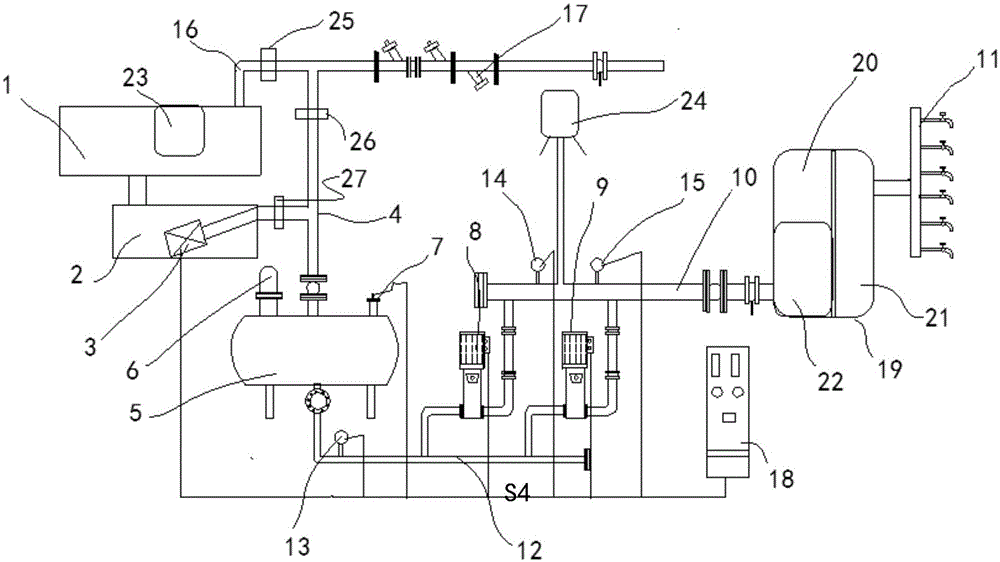

[0017] see figure 1 , a box-type stacked water supply equipment, including a frequency conversion controller 19, a water tank 1 with a built-in sterilizer 23, a steady flow compensation tank 5, a No. 1 frequency conversion pump 8, and a No. 2 frequency conversion pump 9. The steady flow compensation tank includes A water inlet and a water outlet, the bottom of the steady flow compensation tank is provided with a supporting device, and the described steady flow compensation tank is provided with a vacuum suppressor 6; the water outlet of the steady flow compensation tank is connected to the 1 through a suction pipe 12 The water inlet ends of No. 1 variable frequency pump and No. 2 variable frequency pump, the water outlets of No. 1 variable frequency pump and No. 2 variable frequ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com