Floor outer frame fixing structure

A technology for fixing structures and outer frames, which is applied to building structures, floors, buildings, etc. It can solve problems such as easy loosening of fixed structures, falling apart of floor tiles, and lack of stability, so as to save manpower installation costs, save production costs, Easy and quick installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

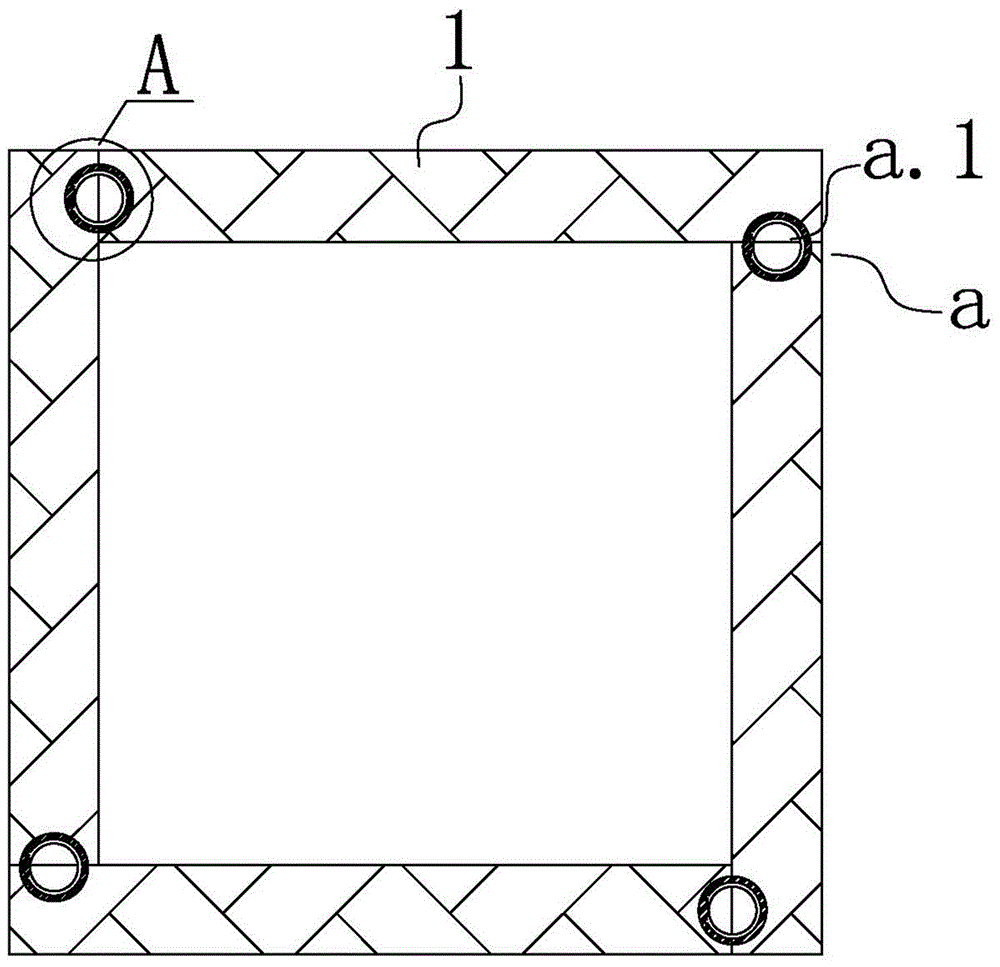

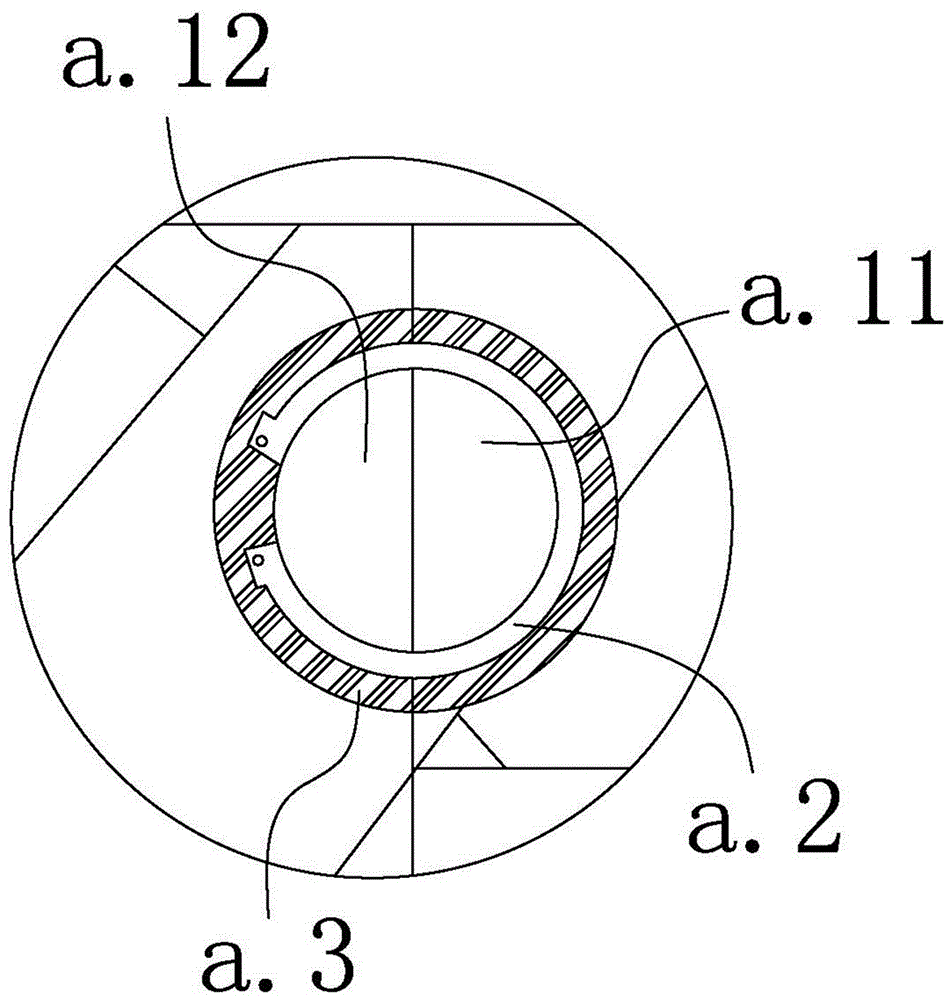

[0034] Example 1: Reference figure 1 and figure 2 , a floor outer frame fixing structure, which is formed by connecting four outer frame parts 1 from end to end, and is in a square shape. A fixing part a is provided at the junction of every two outer frame parts 1, and the fixing part a includes A recess a.3, a cylindrical hoop a.1 that is located in the recess a.3 and protrudes relative to the bottom surface of the recess a.3, and a hoop a that wraps around the hoop a.1 .2. The hoop body a.1 is composed of the first hoop body a.11 and the second hoop body a.12 belonging to two outer frame parts 1 .

Embodiment 2

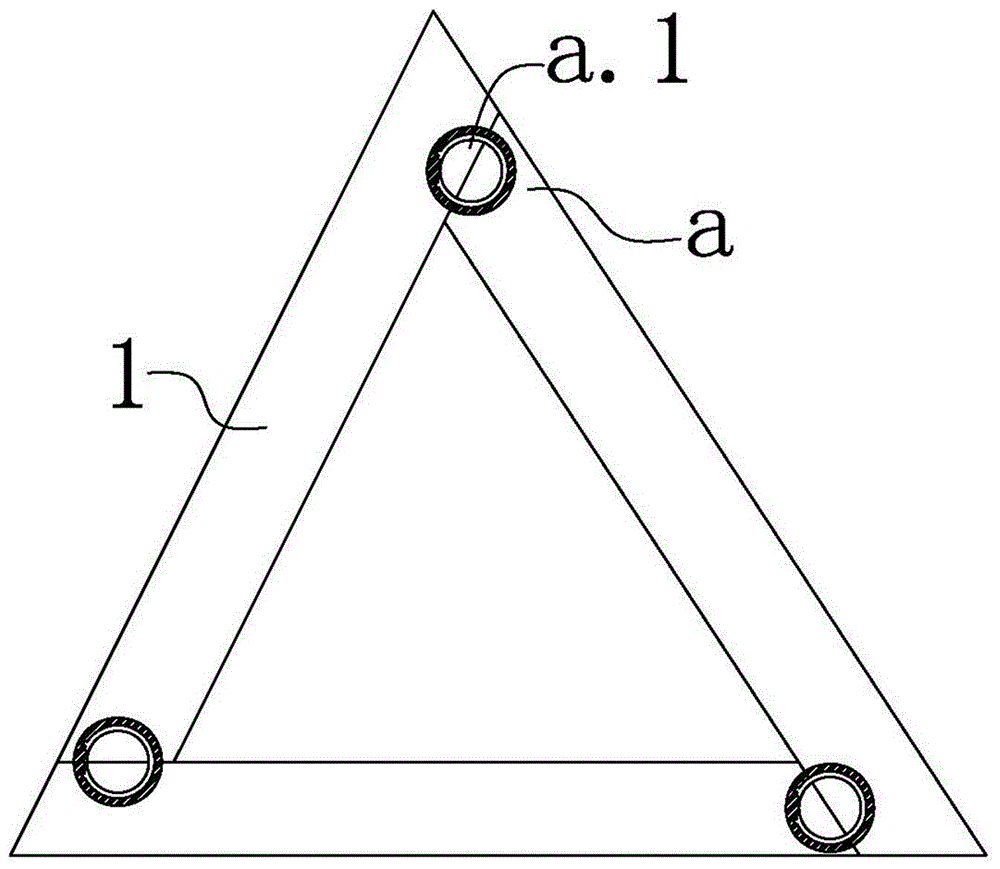

[0035] Example 2: Reference image 3 , a floor frame fixing structure, which is formed by connecting three outer frame parts 1 from end to end, in an equilateral triangle shape, and a fixing part a is provided at the joint of every two outer frame parts 1, and the fixing part a It includes a recess a.3, a cylindrical hoop a.1 located in the recess a.3 and protruding relative to the bottom surface of the recess a.3, and a hoop surrounding the hoop a.1 Part a.2, the hoop body a.1 is composed of the first hoop body a.11 and the second hoop body a.12 belonging to two outer frame parts 1 .

Embodiment 3

[0036] Example 3: Reference Figure 4 , a floor outer frame fixing structure, which is formed by connecting six outer frame parts 1 end to end, and is in the shape of a regular hexagon. A fixing part a is provided at the joint of every two outer frame parts 1, and the fixing part a It includes a recess a.3, a cylindrical hoop a.1 located in the recess a.3 and protruding relative to the bottom surface of the recess a.3, and a hoop surrounding the hoop a.1 Part a.2, the hoop body a.1 is composed of the first hoop body a.11 and the second hoop body a.12 belonging to two outer frame parts 1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com