Air return pipe assembly for refrigerator

An air return pipe and assembly technology, which is applied in the field of refrigerator air return pipe assemblies, can solve the problems of insignificant cold and heat transfer effect, increased material cost, small contact area, etc., and achieves the effects of good implementation effect, improved work efficiency and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

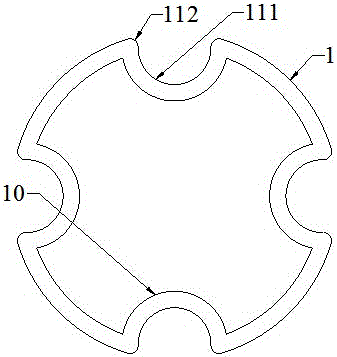

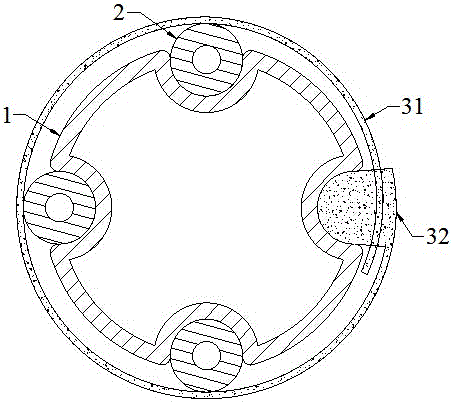

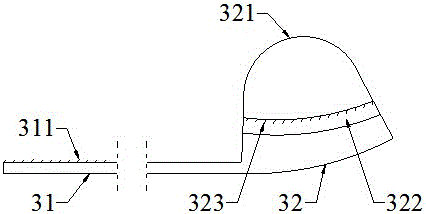

[0020] Such as Figure 1~3 As shown, the air return pipe assembly of the refrigerator includes a return air pipe 1, a capillary 2 and a bandage. The capillary 2 is arranged on the outside of the air return pipe 1, and four axial shafts matching the capillary 2 are arranged on the outside of the air return pipe 1 by stamping technology. Stamping groove, due to the stamping groove made by stamping technology, an arc-shaped convex part 10 corresponding to the stamping groove is formed inside the return air pipe 1, and the convex part 10 makes the inner wall of the return air pipe 1 and the refrigerant in the return air pipe 1 The contact area between them is increased, thereby shortening the heat transfer time and improving the heat transfer efficiency; the stamping groove cooperates with the capillary 2 to maximize the fit between the capillary 2 and the stamping groove, and increases the gap between the capillary 2 and the return air pipe 1 The contact area between the capillar...

Embodiment 2

[0023] Such as Figure 4~5 As shown, on the basis of Embodiment 1, an axial functional groove 113 recessed to the inside of the air return pipe 1 is stamped in the middle of the locking part 111, and an arc corresponding to the functional groove 113 is also formed on the convex part 10. Shaped protrusion 101, the protrusion 101 further increases the contact area between the inner wall of the return air pipe 1 and the refrigerant in the return air pipe 1, thereby further shortening the heat transfer time and further improving the heat transfer efficiency; the functional groove 113 is also further improved The outer surface area of the air return pipe 1 is reduced, and the notch of the functional groove 113 is relatively small. Under the barrier of the capillary 2, the functional groove 113 is easy to form a closed sealed cavity, and the water vapor in the air is liquefied and filled in the sealed cavity, thereby being able to Further promote heat exchange between the capillar...

Embodiment 3

[0025] Such as Figure 6 As shown, on the basis of Embodiment 2, V-shaped axial long grooves 12 are provided on the outside of the air return pipe 1 , and the long grooves 12 are symmetrically distributed around the axis of the air return pipe 1 . The elongated groove 12 cannot further improve the mechanical strength of the air return pipe 1, and the elongated groove 12 can further increase the outer surface area of the air return pipe 1; temperature, the outer surface area of the air return pipe 1 increases, which can further promote the preheating of the refrigerant in the air return pipe 1 before entering the compressor, and improve the efficiency of the compressor; in addition, the long groove 12 is V-shaped, which not only reduces the Not only is the slotting difficult, but also the surface area of the elongated slot 12 can be increased to the maximum, killing two birds with one stone.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com