Hydraulic transmission hold-clamping and tyre push-lifting integrated automobile intelligent carrier

A technology of hydraulic transmission and intelligent handling, applied in the field of car handlers and tire-clamping car handlers, can solve the problems of complex running track of the holding rod, difficult processing, unstable transmission, etc., to reduce control costs and control Difficulty, reduce pre-preparation time, save the effect of special driving force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0070] The present invention will be further described below through non-limiting embodiments and in conjunction with the accompanying drawings.

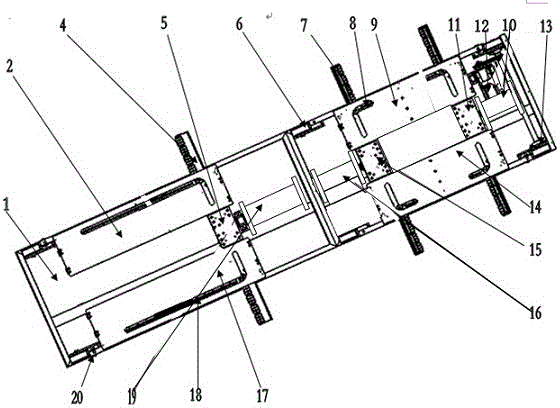

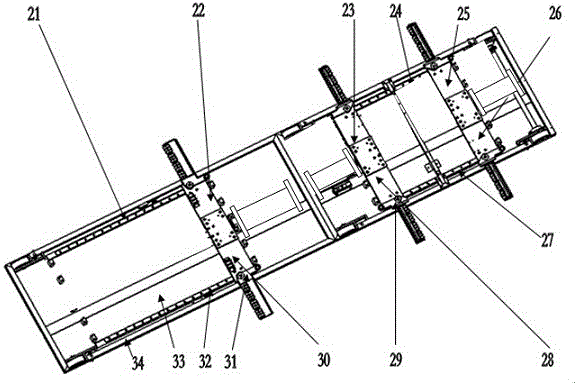

[0071] see Figure 1 to Figure 3 , as shown in the figure, this embodiment discloses a hydraulic transmission holding clamp and push-up tire integrated intelligent vehicle carrier, the carrier includes a chassis 1, and the chassis 1 is provided with a traveling mechanism and a positioning device; One travel motor 12, two active travel wheels 13 and four passive travel wheels 6 are provided. The travel motor 12 drives the chain and then drives two active travel wheels 13. The travel mechanism drives the overall movement of the carrier through the travel motor 12. The chassis 1 is provided with guide wheels 20 on the left frame and the right frame, and the four guide wheels 20 are symmetrically distributed on the four corners of the chassis, rolling along the side of the running track to guide the carrier to move forward and backward,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com