Isolation guardrail for building construction

A technology for building construction and guardrails, which is applied in the direction of buildings, building types, fences, etc., can solve the problems of inability to flexibly adjust the height, affect the performance of the isolation guardrail, and cannot flexibly adjust the length range of the isolation, so as to meet the needs of the construction site.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

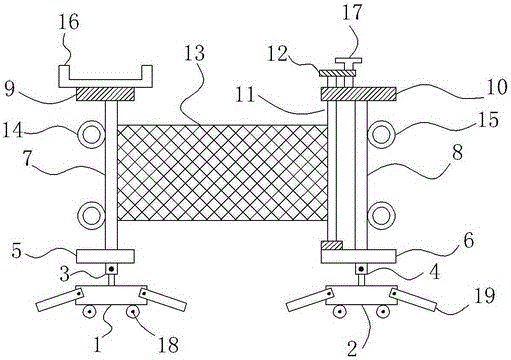

[0013] Such as figure 1 As shown, a construction isolation guardrail includes a left base 1 and a right base 2 respectively, and a left bottom telescopic rod 3 and a right bottom telescopic rod 4 extending vertically upward are respectively provided at the tops of the left base 1 and the right base 2, On the left bottom telescopic rod 3 and the right bottom telescopic rod 4, fastening knobs are respectively provided, and the tops of the left bottom telescopic rod 3 and the right bottom telescopic rod 4 are respectively provided with a left support plate 5 and a right support plate 6; The tops of the left strut 5 and the right strut 6 are respectively provided with a left strut 7 and a right strut 8 extending vertically upwards, and a left top seat 9 is respectively arranged at the tops of the left strut 7 and the right strut 8 And the right top seat 10, on the right top seat 10, a right top seat through hole is provided, and a vertically arranged rotating rod 11 is also embedd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com