Electromagnetic steel plate laying vehicle

An electromagnetic and steel plate technology, applied in roads, buildings, road repairs, etc., can solve the problems of high labor intensity for operators, small construction tasks, and large labor input, so as to reduce construction difficulty and labor intensity, and improve construction efficiency , to achieve the effect of mechanization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below with reference to the embodiments given in the accompanying drawings.

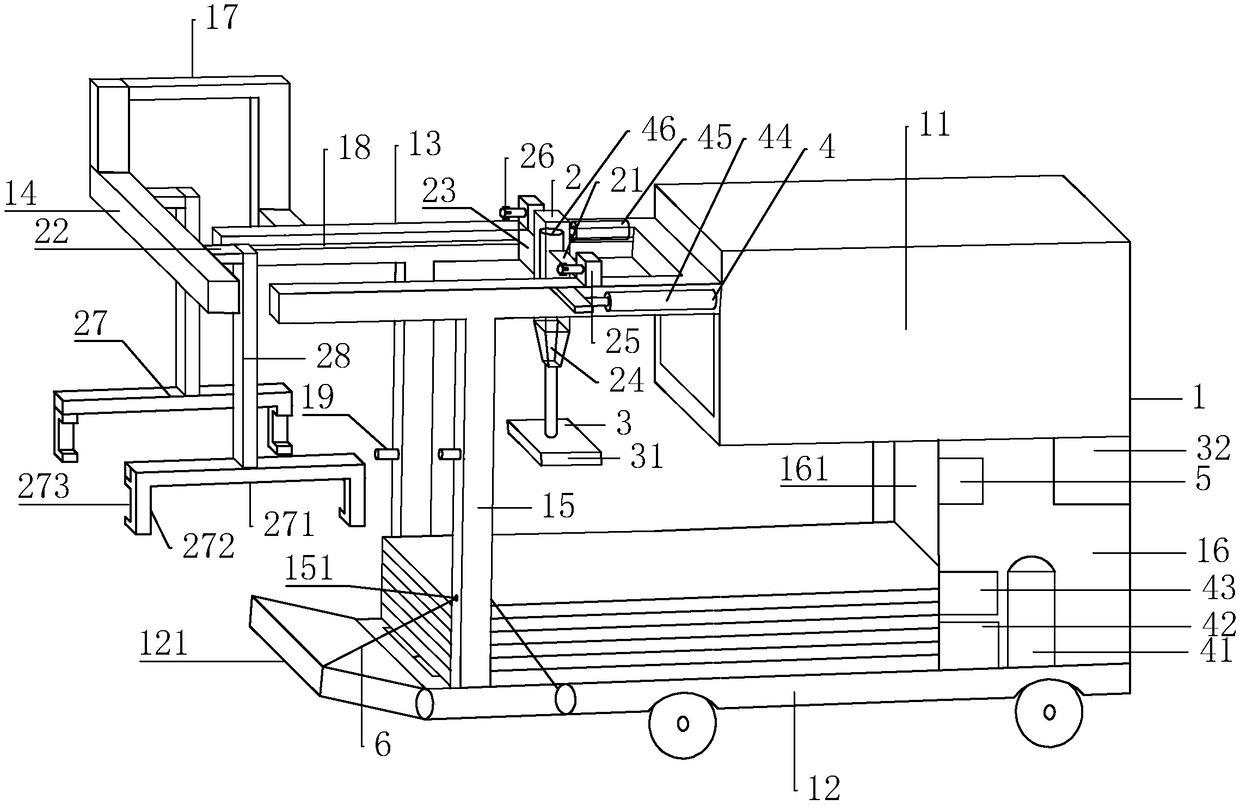

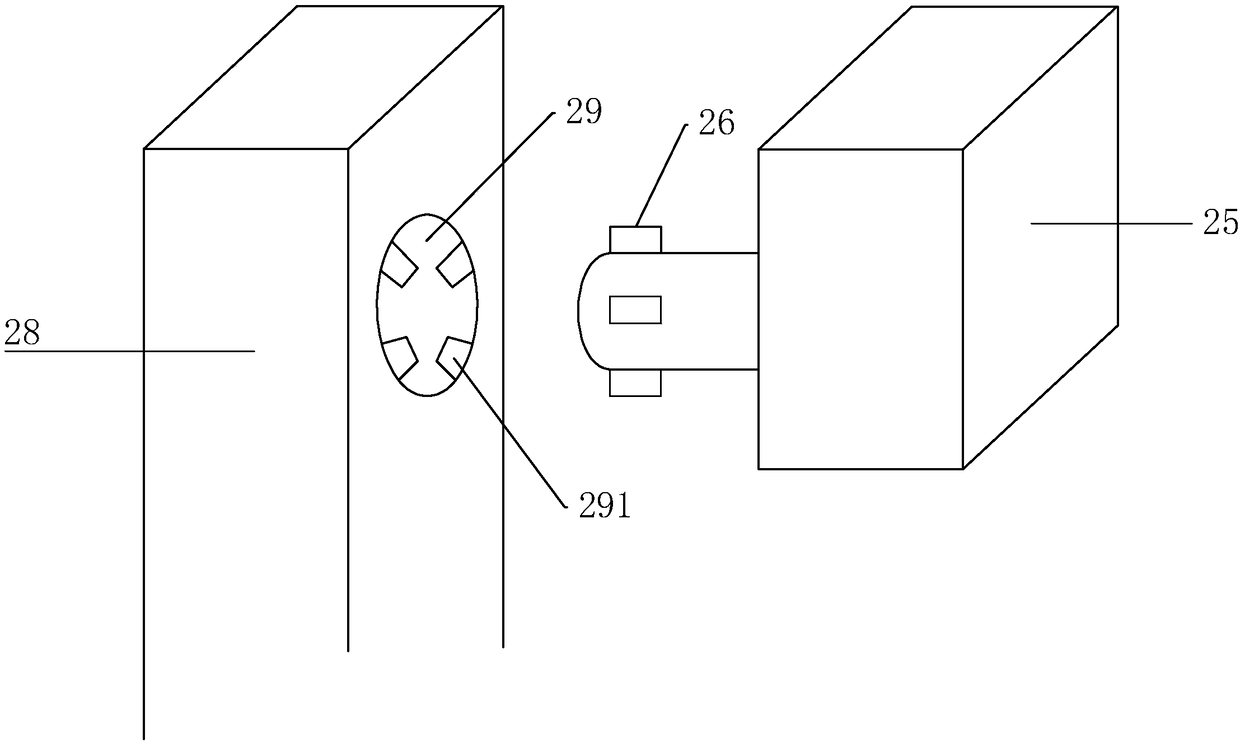

[0023] refer to figure 1 with 2 As shown, an electromagnetic type steel plate laying vehicle of the present embodiment includes a car body 1, a mechanical arm mechanism 2, an electromagnetic mechanism 3, a hydraulic mechanism 4 and a controller 5, and the car body 1 includes a driver's cab 11, an underframe 12, two The first hanging beam 13, the second hanging beam 14 and two support columns 15, the driver's cab 11 is connected on the underframe 12 by the base 16, the window of the driver's cab 11 is towards the tail end of the underframe 12, the first hanging beam 13 Connect on both sides of the underframe 12 through the support column 15, the second hanging beam 14 is connected on the first hanging beam 13 through the connecting column 17, the first hanging beam 13, the second hanging beam 14 and the underframe 12 are parallel, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com