A high-precision valved micropump driven by a temperature-controlled shape memory alloy

A technology of memory alloy and memory alloy spring, which is applied to components of pumping devices for elastic fluids, pumps with flexible working elements, pumps, etc., can solve the problem of large volume of driving devices, poor one-way cut-off performance, and driving frequency. Low-level problems, to achieve the effect of good one-way cut-off performance, easy production, and high power-to-weight ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make the technical solution and advantages of the present invention clearer, the embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings: this embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and The specific operation process, but the scope of protection of the present invention is not limited to the following examples.

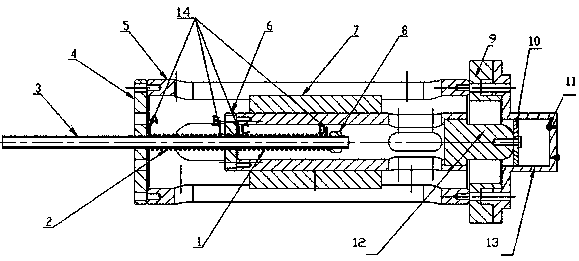

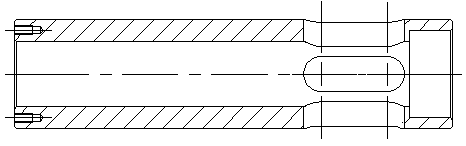

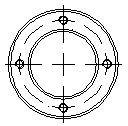

[0028] figure 1 It is a sectional view of the central axis of the overall structure of the present invention, figure 2 It is a sectional view along the axis of the piston I of the present invention, image 3 It is the left side view of the piston I of the present invention, see below figure 1 , 2 , 3 for examples.

[0029] The micropump includes a temperature-controlled shape memory alloy spring II (1), a temperature-controlled shape memory alloy spring I (2), a cooling ceramic tube (3), an upper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com