Piezoelectric stack micro-pump based on triangle and lever principle

A piezoelectric stack, lever principle technology, applied in the components of pumping devices for elastic fluids, pumps with flexible working elements, piezoelectric effect/electrostrictive or magnetostrictive motors, etc., can solve the problem. Increase the structure size of the micro-pump, poor one-way cut-off performance, and low control accuracy, etc., to achieve the effect of good one-way cut-off performance, fast response speed, and high control accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The embodiments of the present invention are described in detail below. This embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the protection scope of the present invention is not limited to the following implementation example.

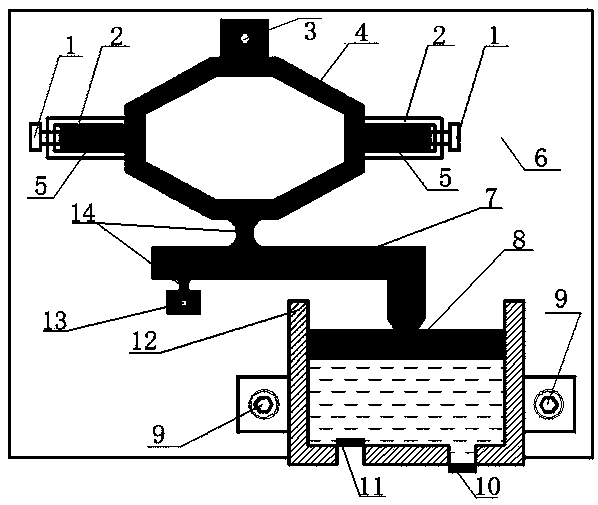

[0019] A kind of piezoelectric stack micropump based on the principle of triangle and lever that the present embodiment relates to, such as figure 1 As shown, including pre-tightening screw (1), piezoelectric stack positioning slot (2), screw I (3), triangle magnifying mechanism (4), piezoelectric stack (5), fixing plate (6), lever magnifying Mechanism (7), piston (8), screw II (9), shut-off valve I (10), shut-off valve II (11), pump body (12), screw III (13), flexible hinge (14), based on a triangle The amplifying mechanism based on the lever principle is assembled on the fixed plate (6), and the central axis pos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com