New adhesive filtration device

A filter device and adhesive technology, applied in the direction of filtration and separation, fixed filter elements, chemical instruments and methods, etc., can solve the problems of not taking into account the refined operation of fine products, unreasonable structure setting, inconvenient use, etc., to achieve The effect of adjustable quantity, simple structure and convenient repeated use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

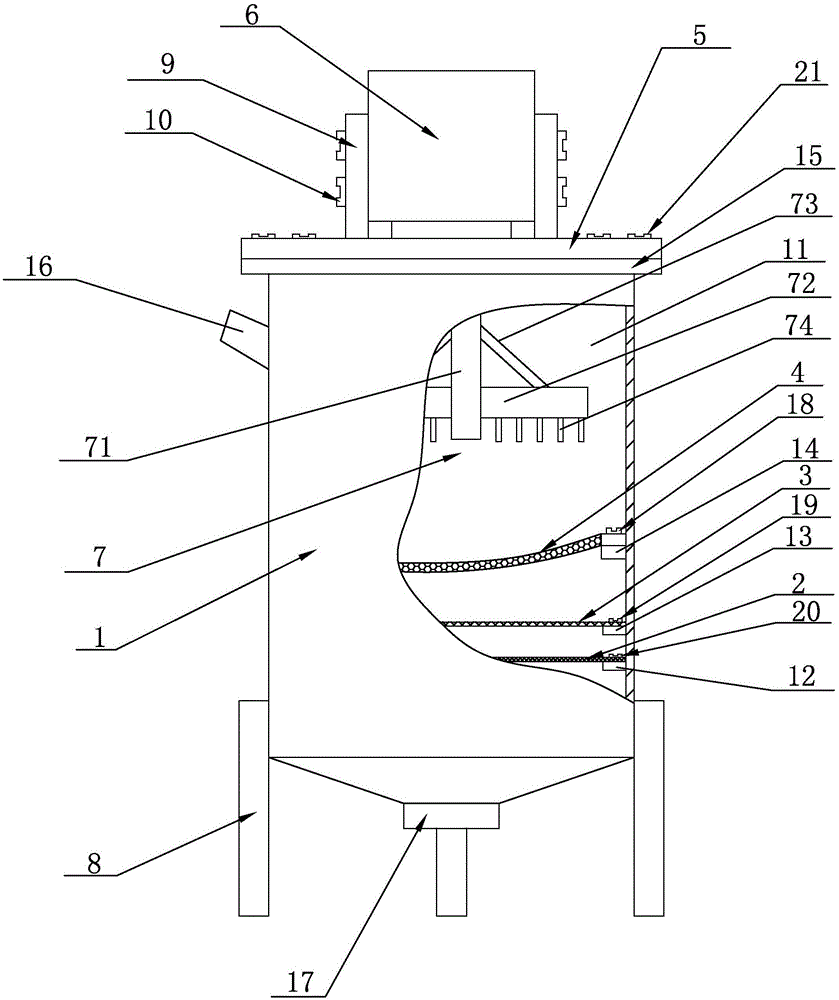

[0018] see figure 1 , a new type of adhesive filter device disclosed in the present invention, comprising a housing 1, a filter chamber 11 is arranged in the housing 1, and first filter screen fixing blocks are sequentially arranged on the inner wall surface of the filter chamber 11 from bottom to top 12. The second filter net fixing block 13 and the third filter net fixing block 14, the first filter net fixing block 12, the second filter net fixing block 13 and the third filter net fixing block 14 are all integrated with the housing 1 , the first filter net fixed block 12 is detachably provided with the first filter net 2, the second filter net fixed block 13 is detachably provided with the second filter net 3, and the third filter net fixed block 14 is detachably provided with There is a third filter screen 4, the upper end of the housing 1 is integrally provided with a connecting flange 15, the connecting flange 15 is provided with an upper cover 5, the middle part of the u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com