Split type roller structure with oil grooves

A split type, oil tank technology, applied in the direction of metal processing equipment, forming tools, manufacturing tools, etc., can solve problems such as unsmooth rotation, achieve the effect of solving overall processing, reducing running resistance, and solving process problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention is described in detail below in conjunction with accompanying drawing:

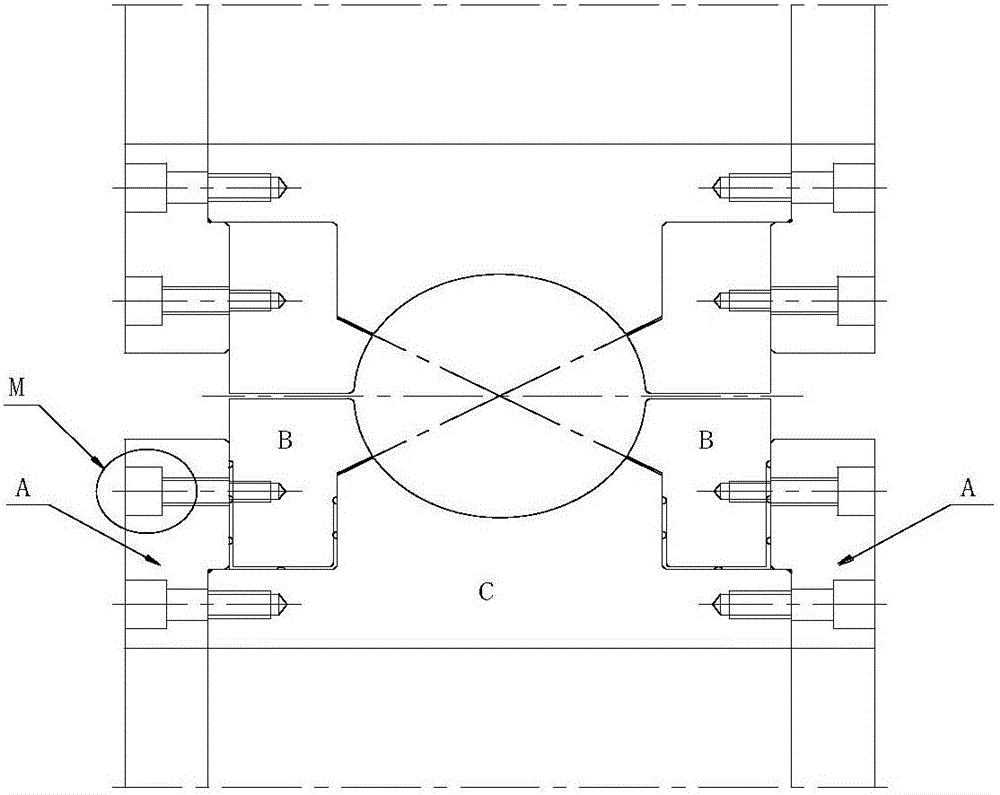

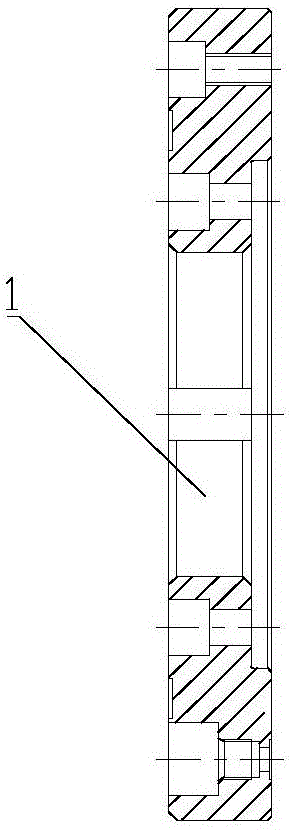

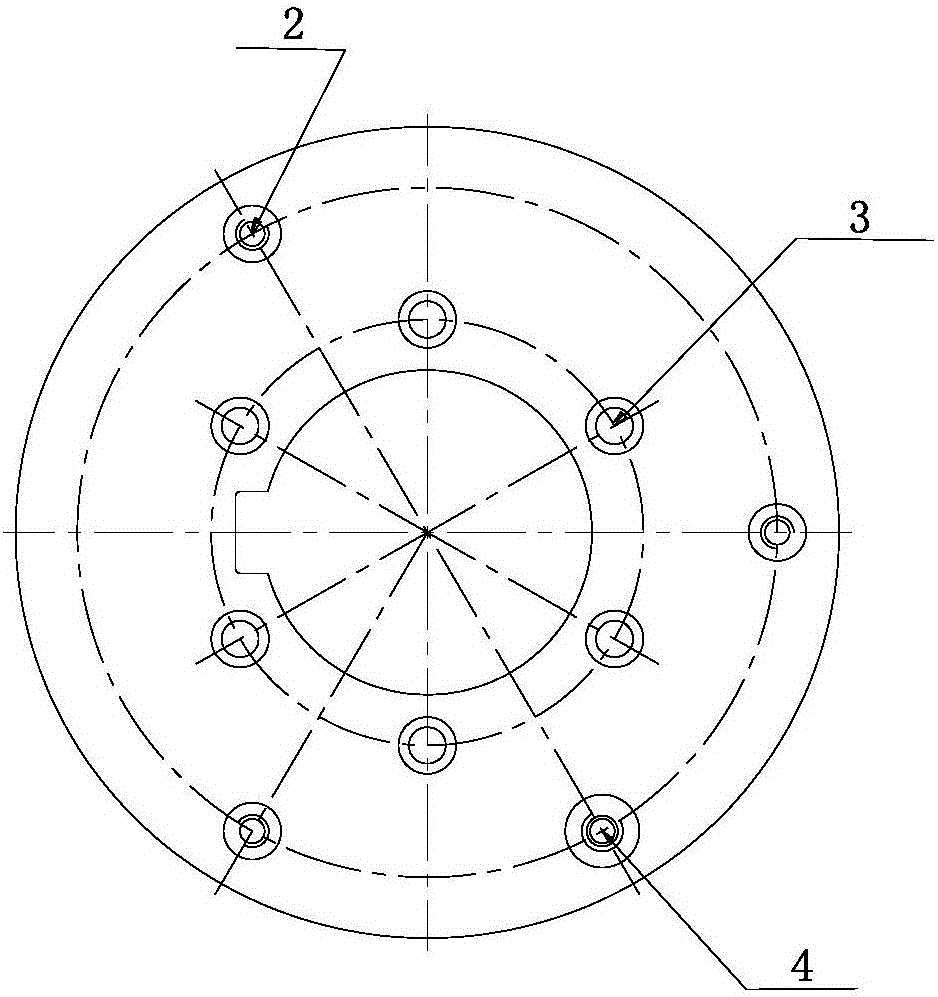

[0028] Such as figure 1 As shown, it includes two sets of split roll structures with oil grooves, and each component roll structure includes A roll, B roll, and C roll. The B roll includes two, and its center relative to the C roll It is arranged symmetrically on the shoulder of the C roller and installed coaxially with the C roller. After the two B rollers are combined with the C roller, a semicircular working surface is formed. The A roller includes Two, which are arranged on the outside of the shoulder 11 of the C roller relative to the center line of the C roller and are connected coaxially with the C roller by bolts. The B roller and the A roller at the corresponding position are also connected by bolts M, so that When the roll is processed, the A roll, the B roll and the C roll form a whole; along the axial direction of the B roll, a multi-circle annular oil groove is p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com