A method and equipment for forming polyurethane foamed metal profiles in inner cavity by threading method

A technology of foaming metal and molding method, applied in the field of building door and window materials, can solve the problems of reduced heat insulation and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

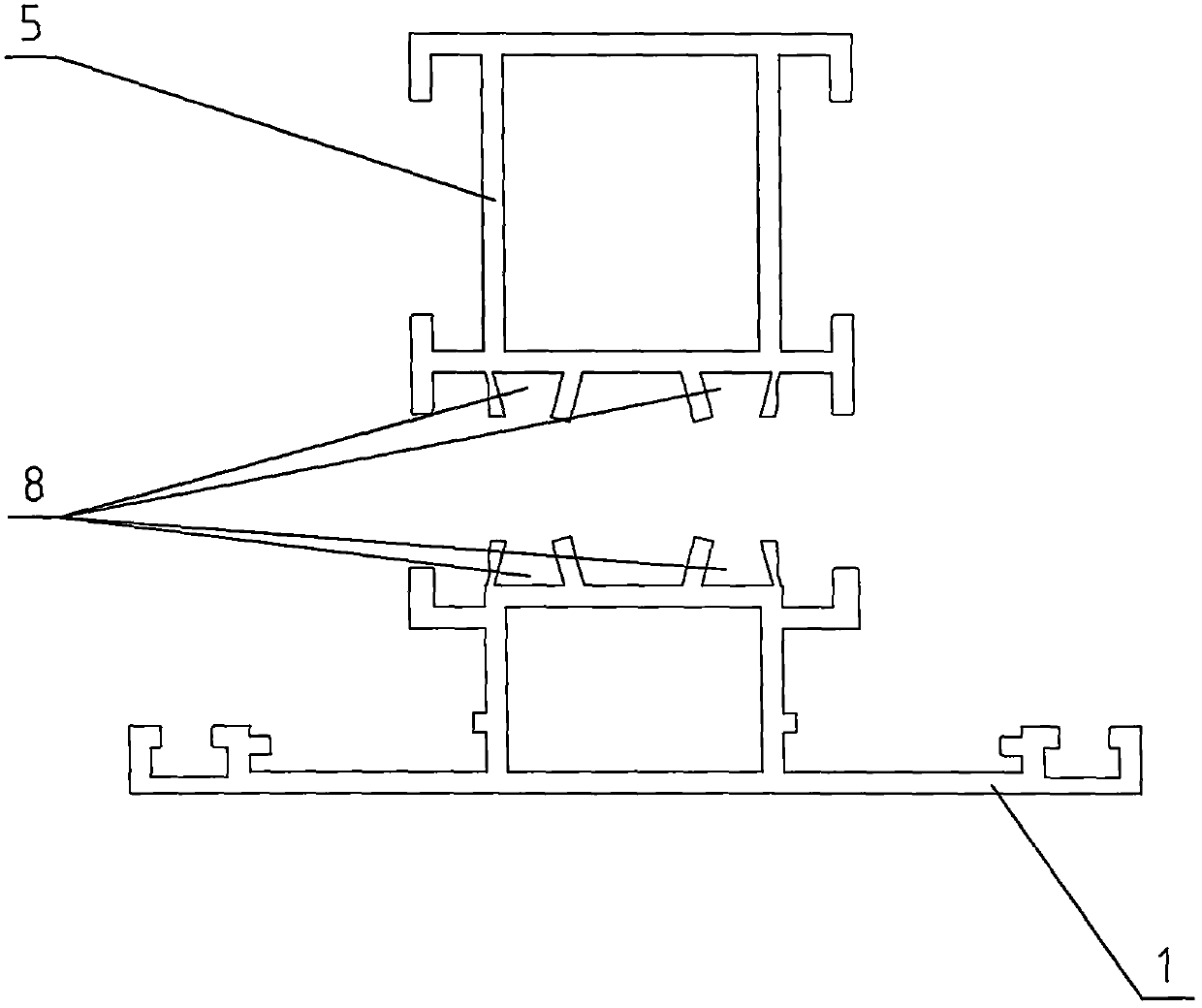

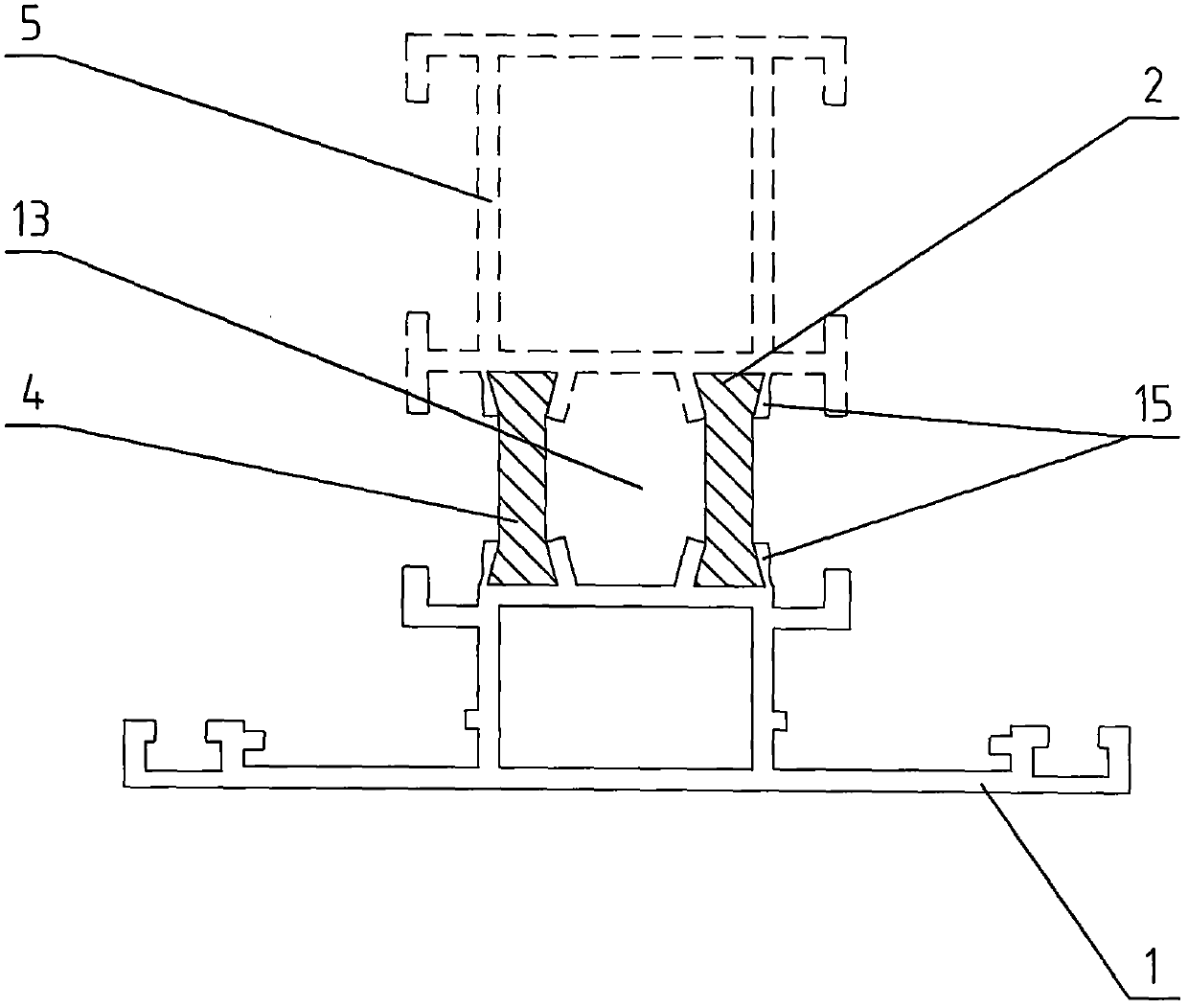

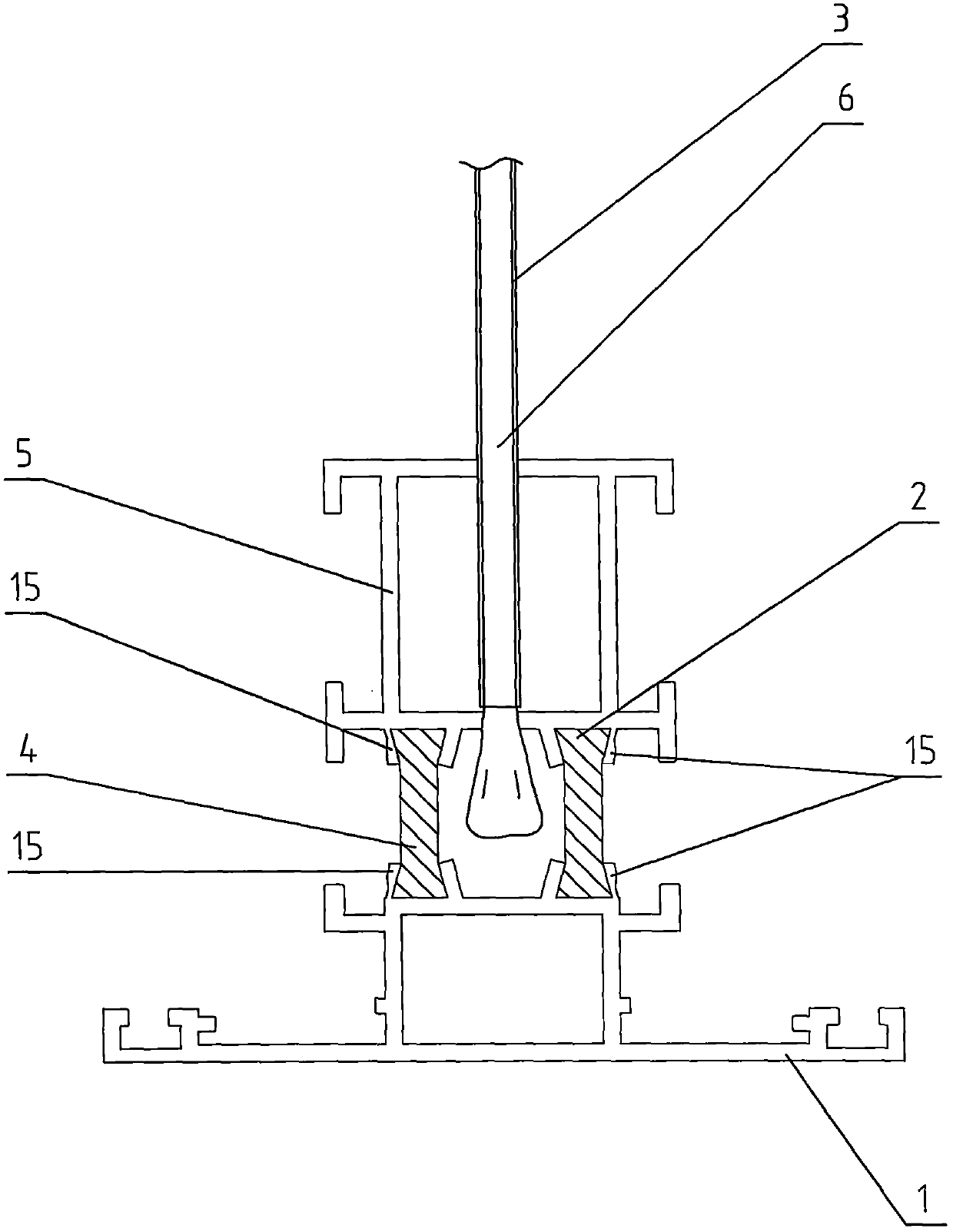

[0073] Specific implementation mode one: as Figure 1 to Figure 5 As shown, a method for forming polyurethane foamed metal profiles in the cavity of the strip-threading method is used to produce polyurethane foamed metal profiles in the cavity of the strip-threading method;

[0074] It is characterized in that the molding steps are as follows:

[0075] Step 1, first manufacture profiles A1 and B5 with dovetail notches 8 respectively, and the dovetail notches 8 on the profiles A1 and B5 are symmetrically arranged and arranged longitudinally along the profiles; cut the profiles A1 and B5 into equal length;

[0076] Step 2, use a plastic extruder to produce the threading strip, the upper and lower ends of the threading section have a shape corresponding to the dovetail notch 8, and the middle of the section is a rectangle; cut the threading strip into a threading strip with the same length as the profile A2, wearing strip B4, marking the wearing strip as wearing strip A2, weari...

specific Embodiment approach 2

[0084] Specific implementation mode two: as Figure 1 to Figure 5 As shown, the difference between the second embodiment and the first embodiment is that the profile A1 is fixed, while the glue injection nozzle 3 and the profile B5 move.

[0085] A method for forming polyurethane foamed metal profiles in inner cavity by threading method, which is used for producing polyurethane foamed metal profiles in inner cavity by threading method;

[0086] It is characterized in that the molding steps are as follows:

[0087] Step 1, first manufacture profiles A1 and B5 with dovetail notches 8 respectively, and the dovetail notches 8 on the profiles A1 and B5 are symmetrically arranged and arranged longitudinally along the profiles; cut the profiles A1 and B5 into equal length;

[0088] Step 2, use a plastic extruder to produce the threading strip, the upper and lower ends of the threading section have a shape corresponding to the dovetail notch 8, and the middle of the section is a rec...

specific Embodiment approach 3

[0096] Specific implementation mode three: as Figure 1 to Figure 5 As shown, the molding method of inner-cavity polyurethane foam metal profiles by threading method, the steps also include placing the workpiece in the shaping mold for 2-20 minutes, the ambient temperature of the shaping mold is 10-25°C, and the mixed two-component Polyurethane is foamed and solidified in the cavity surrounded by profile A1, profile B5, threading strip A2, and threading strip B4 to form the space where polyurethane foam strip 7 fills the cavity 13, which plays the role of bonding and increasing strength; Guarantee the relative positions of profile A1, profile B5, threading strip A2, and threading strip B4.

[0097] Other compositions and connections are the same as those in Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com