Automatic changing device for fiber material of 3D printer and 3D printer

A 3D printer and automatic replacement technology, applied in the field of 3D printing, can solve the problems of complex silk material replacement mechanism, cumbersome silk material replacement, low reliability, etc., to achieve high promotion and application value, improve reliability and stability, and compatibility. Sexually wide effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other. The present invention will be described in detail below with reference to the accompanying drawings and examples.

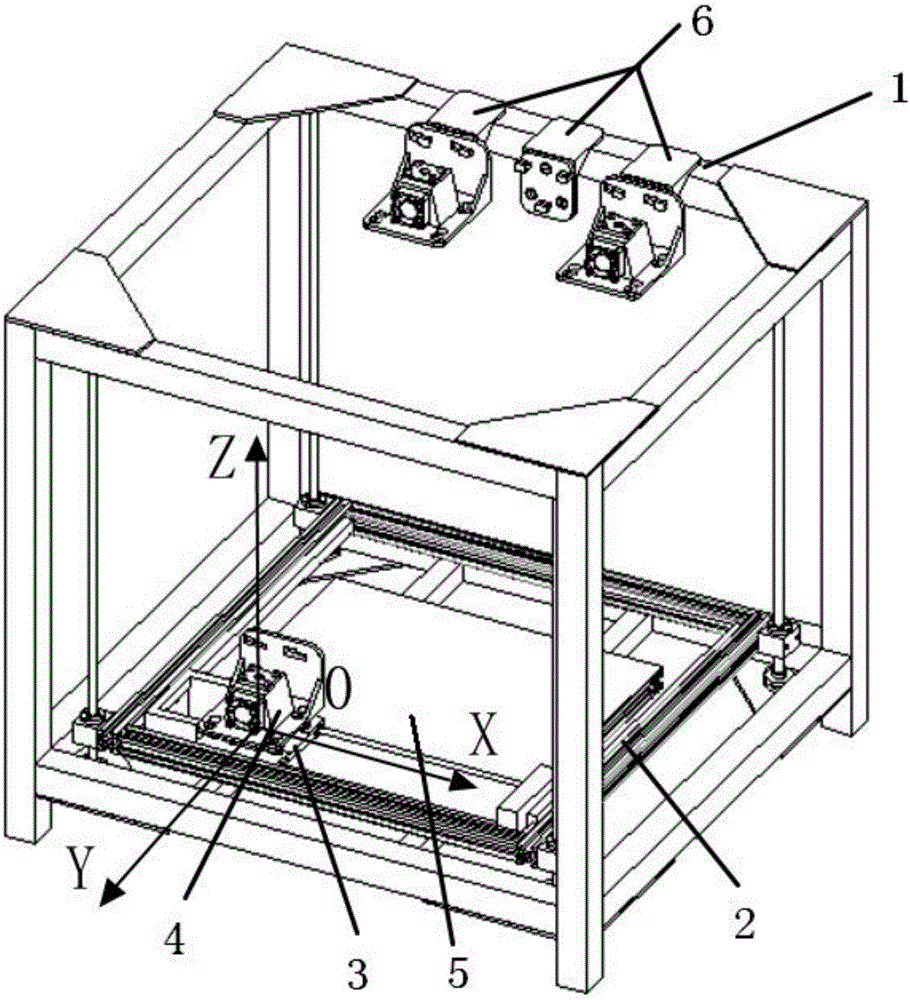

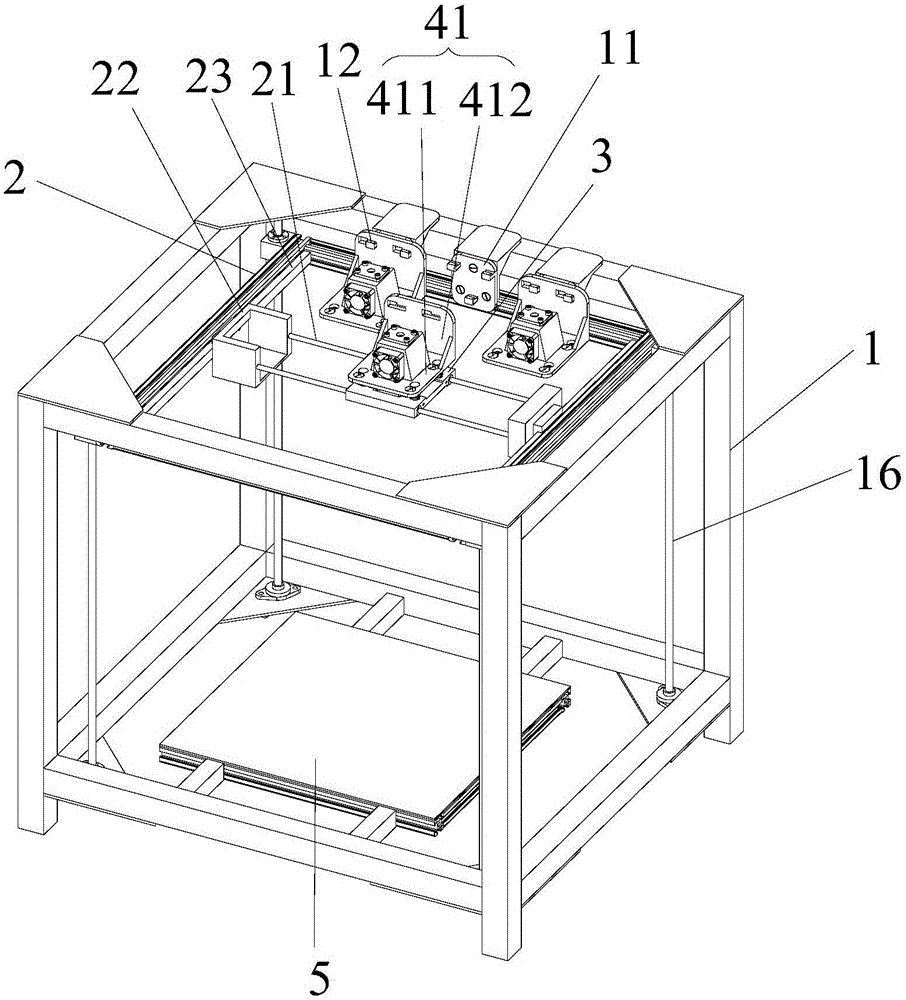

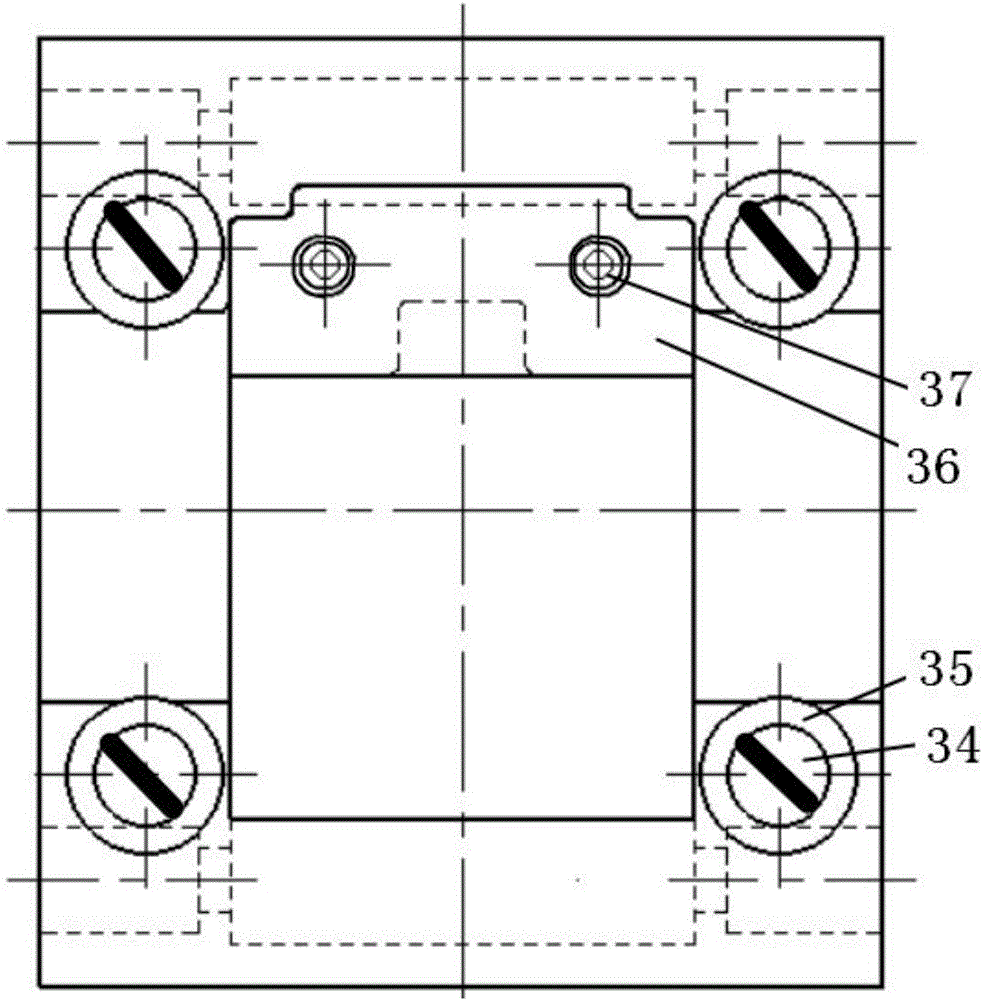

[0043] A preferred embodiment of the present invention provides a 3D printer filament automatic replacement device, with reference to figure 1 and figure 2The device in this embodiment includes an outer frame 1 and an inner frame 2 that is arranged in the outer frame 1 and can move up and down relative to the outer frame 1 along the height direction; the outer frame 1 is provided with more than two detachable fixed printing nozzles 4 The first positioning mechanism, the inner frame 2 is provided with a nozzle fixing plate 3 that moves along its plane, the upper surface of the nozzle fixing plate 3 is provided with a plurality of countersunk screws 34, and the outer sleeve of each countersunk...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com