Film sealing and cutting machine

A technology of sealing and cutting machine and film, which is applied in the direction of packaging/bundling items, packaging, and wrapping items, etc. It can solve problems such as high difficulty, affecting production progress, and cumbersome operation, and achieves convenient operation, shortened adjustment time, and improved production efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below in conjunction with the embodiments given in the accompanying drawings.

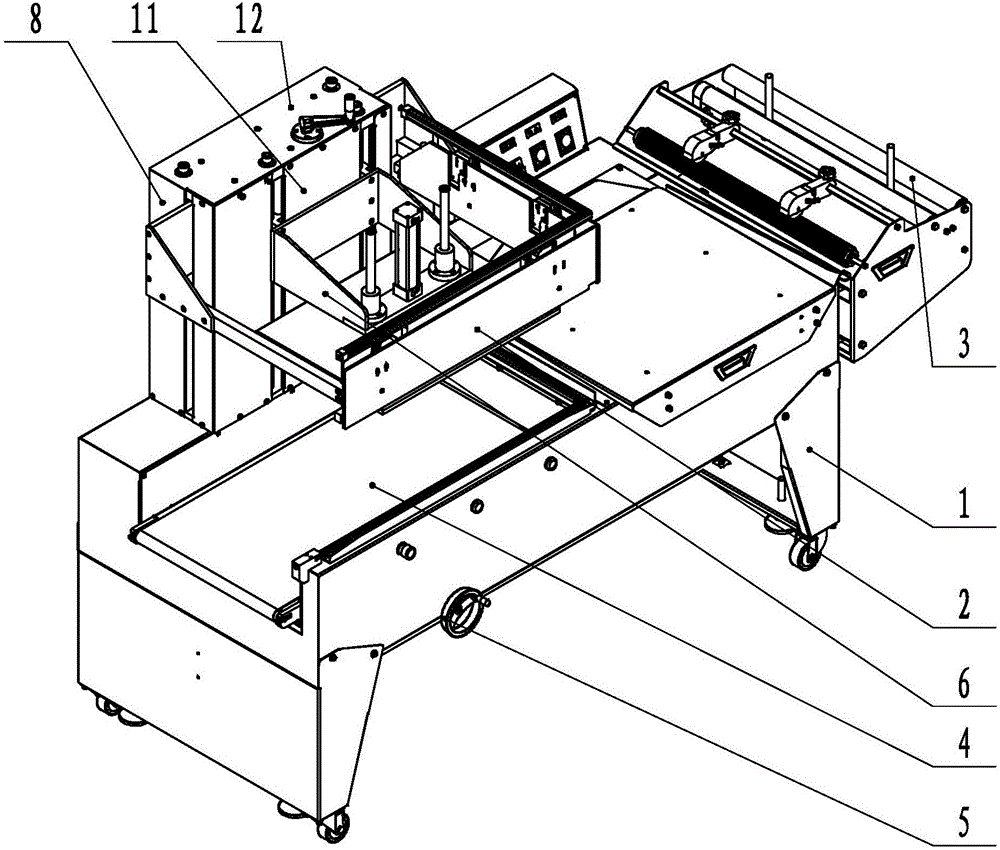

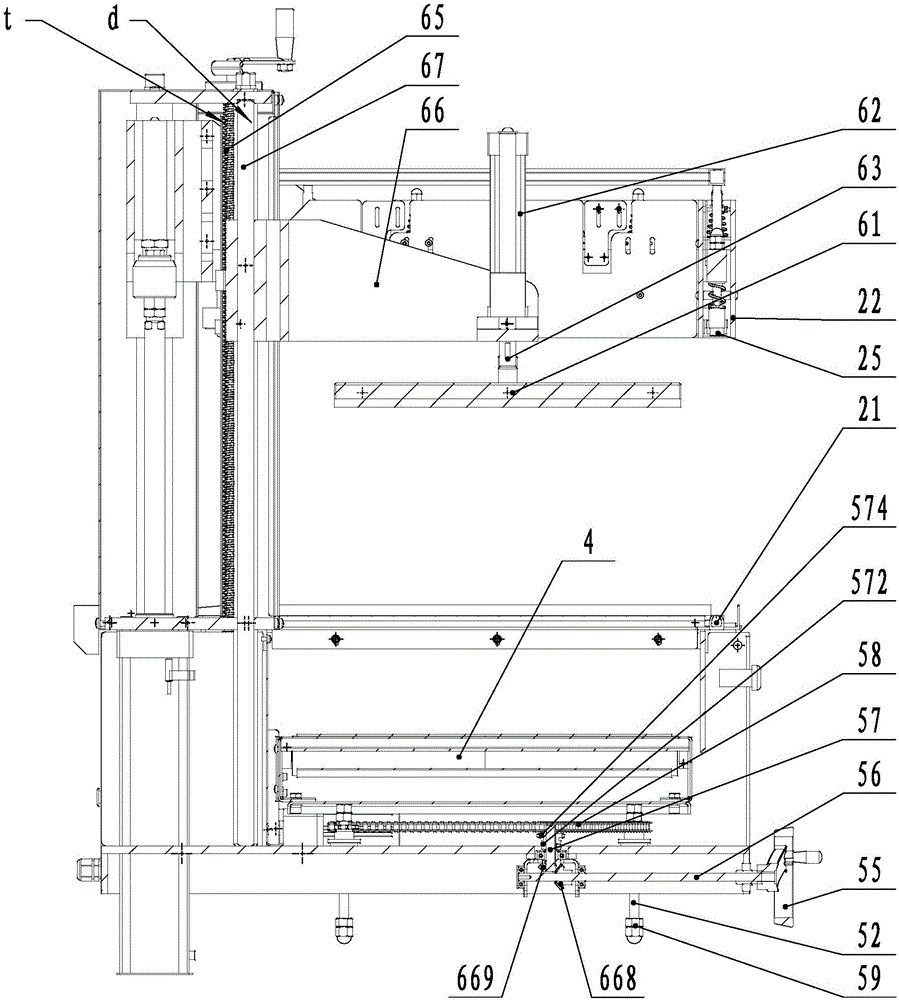

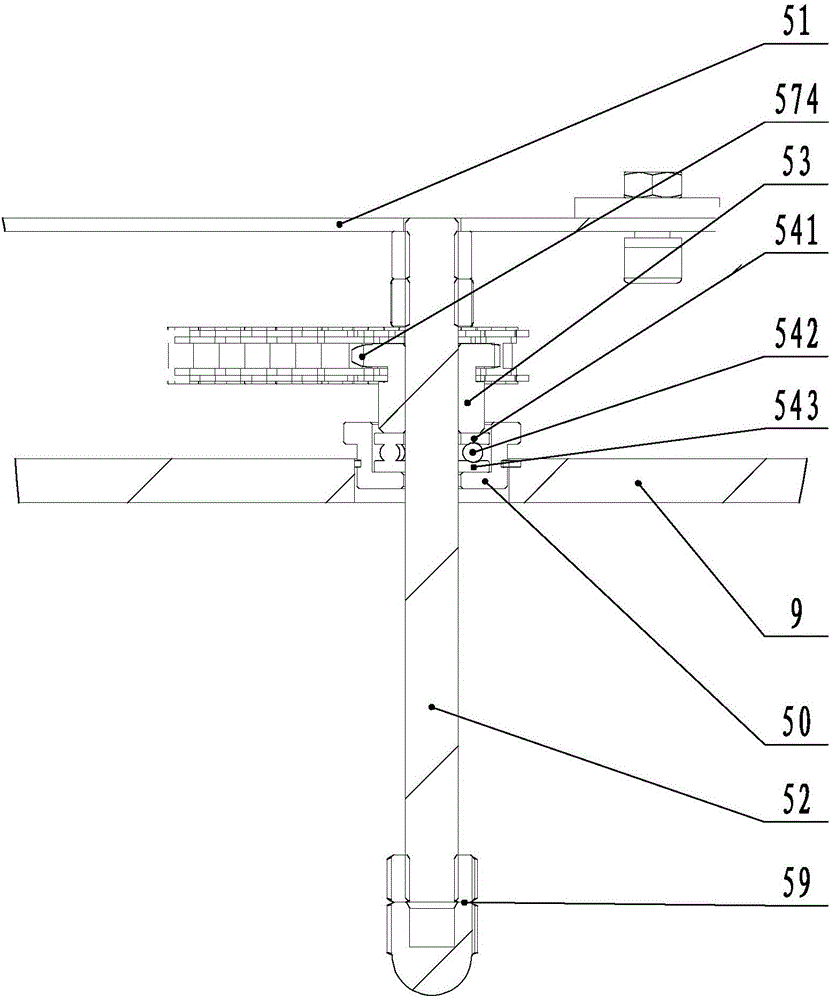

[0024] refer to Figure 1 to Figure 8 As shown, a film sealing and cutting machine includes a frame 1, a compression plate 61, a heat-sealing cutter 25 and a storage platform 4 arranged on the frame 1, and the compression plate 61 and the heat-sealing cutter 25 can be set up and down. Above the storage platform 4, the frame 1 is provided with a heat-seal cutting edge 21 for cooperating with the heat-seal cutter 25 relative to the position of the heat-seal cutter 25, and the compression plate 61 cooperates with the storage platform 4 to compress to be packaged. After the object is finished, the heat-sealing cutter 25 and the heat-sealing cutting edge 21 cooperate with each other to seal and cut the film. It is characterized in that: the position of the frame 1 relative to the side of the storage platform 4 is provided with a fixed fram...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com