A corrosion-resistant and strengthenable rare-earth aluminum alloy

A technology of aluminum alloy and rare earth, applied in the field of rare earth alloy materials, to achieve good corrosion resistance and strengthenable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

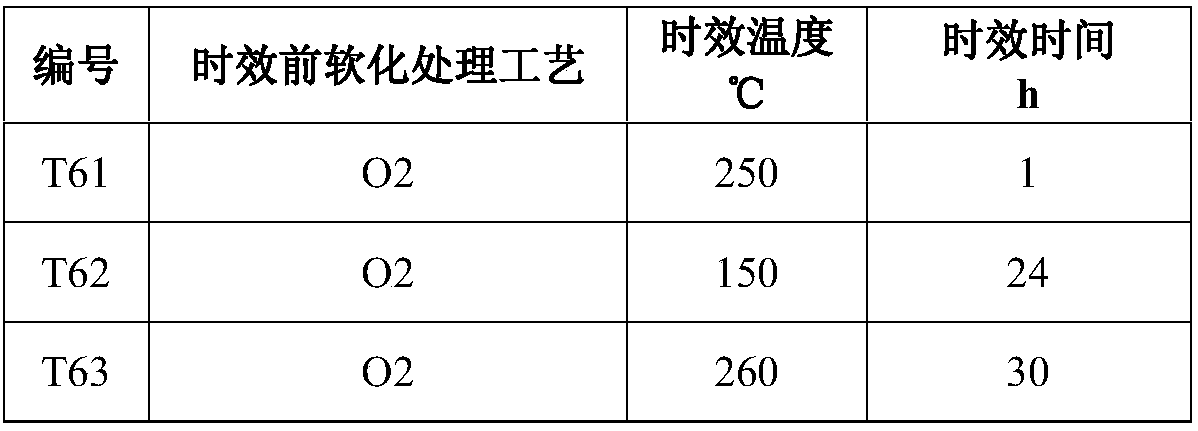

[0034] The contents of the alloy elements in the 1-6# alloys are shown in Table 1. The raw materials used are all pure metals or intermediate alloys with more than 99.8%, and the ingots are obtained by smelting. The ingots were analyzed by impurity elements, and the results are shown in Table 2. When the ingot is softened, the softening process is shown in Table 3, the cooling method is air cooling, and the softened state of the sample is recorded as O state. When the ingot is strengthened and toughened, the softening treatment process shown in Table 3 is followed by artificial aging treatment. The artificial aging treatment process is shown in Table 4, and the sample state is recorded as T6 state. The performance test results of the alloy in different heat treatment states are shown in Table 5. Among them, the samples in the T62 state were subjected to the salt spray test in the YL-40C salt spray test chamber. Corrosion ω is the weight loss of the sample before and after co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com