A kind of preparation and processing method of concave-convex slub yarn

A processing method and technology of slub yarn, applied in the field of textile yarn, can solve the problems of single pattern style, uneven thickness distribution, poor anti-pilling performance, etc., and achieve the effect of increasing the added value of sales

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

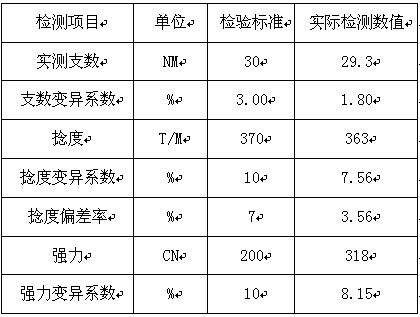

Embodiment 1

[0016] The preparation and processing method of a kind of concave-convex shape slub yarn described in this embodiment, the steps are as follows:

[0017] The first step is the selection of raw materials: 100% 17.5um mercerized merino wool;

[0018] The second step, dyeing treatment: mix 17.5um mercerized merino wool at room temperature with a bath ratio of 1:8, and add 0.5g / L glacial acetic acid and 0.5g / L leveling agent Abaig B And add 1.5% reactive dyes for wool from light to dark, and keep it for 10 minutes, then raise the temperature at 0.8°C per minute to 50°C, then raise the temperature to 85°C at 1°C per minute, and keep it for 50 minutes, then stop the temperature rise , let it cool down to 70°C at a rate of 0.8°C per minute, and keep it for 5 minutes, then cool down to 50°C at a rate of 1°C per minute, and finally cool naturally to complete the dyeing process, and keep the pH value at 4; 17.5 throughout the dyeing process um mercerized merino wool has a pH value of 5...

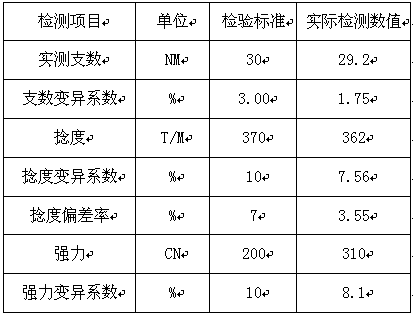

Embodiment 2

[0025] The preparation and processing method of a kind of concave-convex shape slub yarn described in this embodiment, the steps are as follows:

[0026] The first step is the selection of raw materials: 100% 17.5um mercerized merino wool;

[0027] The second step, dyeing treatment: mix mercerized merino wool at room temperature with a bath ratio of 1:9, and add 0.8g / L glacial acetic acid, 0.8g / L leveling agent Abaig B and add The amount is 2% reactive dyes for wool from light to dark, and keep it for 10 minutes, then increase the temperature at 0.8°C per minute to 40°C, then increase the temperature at 1°C per minute to 85°C, and keep it for 55 minutes, then stop the temperature rise, so that It cools down to 70°C at 0.8°C per minute and keeps it for 5 minutes, then cools down to 50°C at 1°C per minute, and finally cools naturally to complete the dyeing process, and the pH value is kept at 5 throughout the dyeing process; Mercerized Merino The PH value of wool after dyeing i...

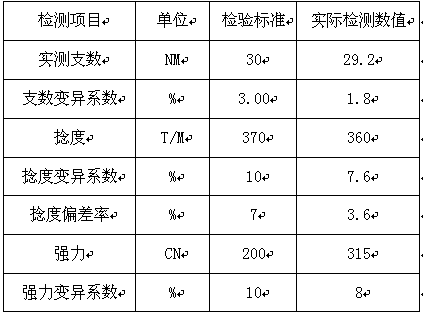

Embodiment 3

[0034] The preparation and processing method of a kind of concave-convex shape slub yarn described in this embodiment, the steps are as follows:

[0035] The first step is the selection of raw materials: 100% 17.5um mercerized merino wool;

[0036] The second step, dyeing treatment: mix mercerized merino wool at room temperature with a bath ratio of 1:10, and add 1g / L of glacial acetic acid, 1g / L of leveling agent Abaig B and the addition amount is Use reactive dyes for 3% wool from light to dark, and keep it for 10 minutes, then raise the temperature at 0.8°C per minute to 50°C, then raise the temperature at 1°C per minute to 90°C, and keep it for 60 minutes, then stop the temperature rise and make it Cool down at 0.8°C per minute to 70°C and keep it for 5 minutes, then cool down at 1°C per minute to 50°C, and finally cool down naturally to complete the dyeing process, and keep the pH value at 6 throughout the dyeing process; After dyeing, the pH value is 7, that is, the pH ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com