A kind of light color ceramic tile with decorative pattern and preparation method thereof

A ceramic tile and patterned light technology, which is applied in the field of architectural ceramics production, can solve the problem that the color of the decorative pattern cannot change color with the light, and achieve the effect of ensuring the decorative effect of the pattern, avoiding mechanical friction, and improving the decorative effect and aesthetic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

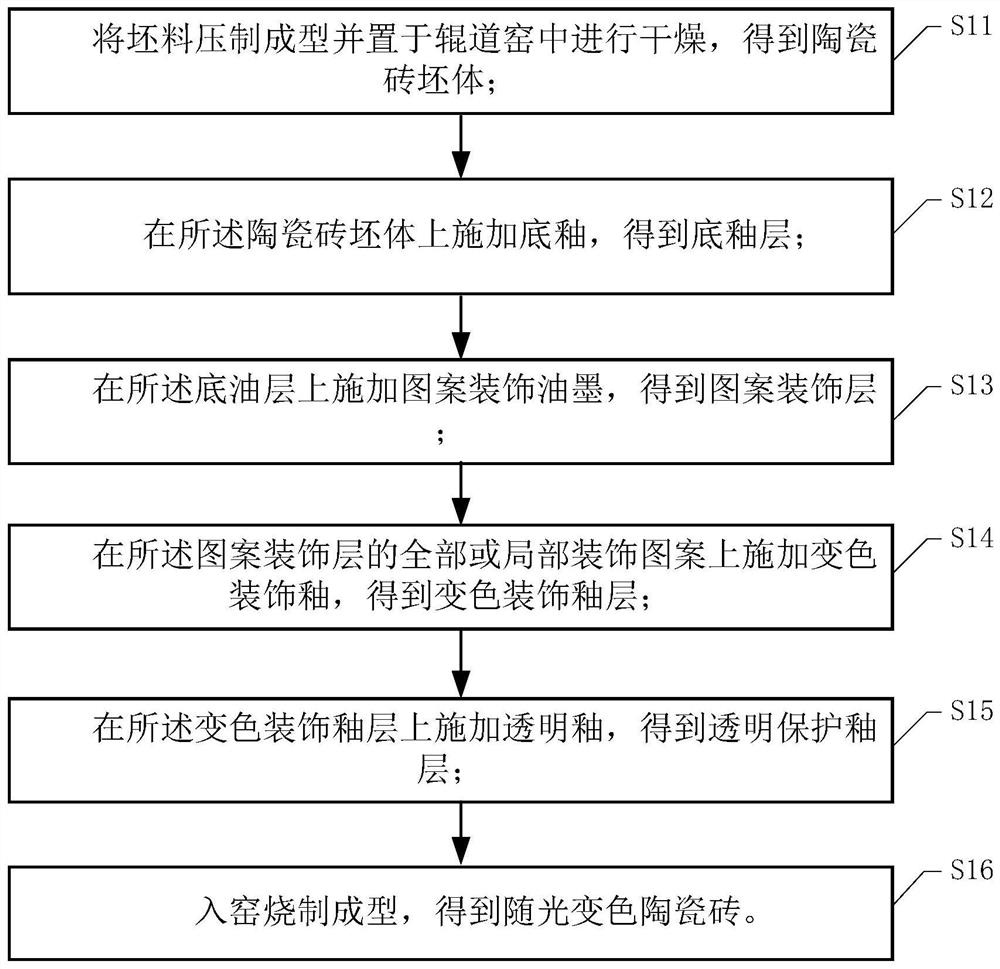

[0074] This embodiment provides a method for preparing a photochromic ceramic tile with a decorative pattern, comprising:

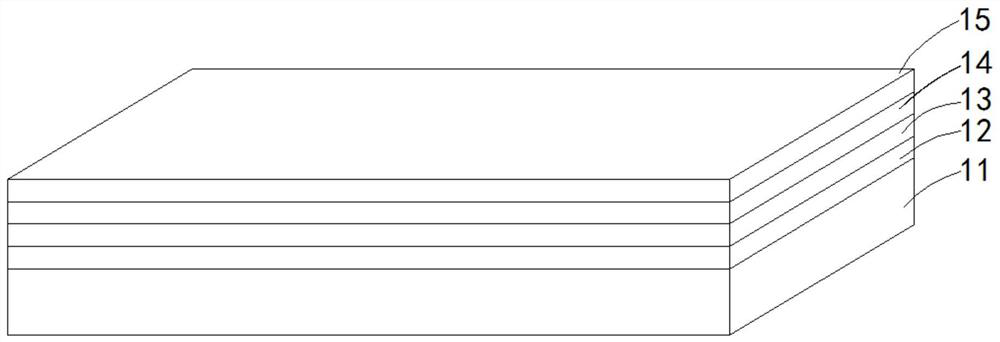

[0075] Step 11, pressing the blank and placing it in a roller kiln for drying to obtain a ceramic brick body;

[0076] Step 12, applying an underglaze on the ceramic tile body to obtain an underglaze layer;

[0077] Step 13, applying pattern decoration glaze ink on the bottom glaze layer to obtain a pattern decoration layer;

[0078] Step 14, applying a color-changing decorative glaze on all or part of the decorative pattern of the pattern decoration layer to obtain a color-changing decorative glaze layer;

[0079] Step 15, applying a transparent glaze on the color-changing decorative glaze layer to obtain a transparent protective glaze layer;

[0080] Step 16, firing in a kiln to obtain ceramic tiles that change color with light.

[0081] Further, the chemical composition of the photochromic glaze is in mass percent, including:

[0082] SiO 2 41.6~...

Embodiment 2

[0102] This embodiment provides a method for preparing photochromic ceramic tiles with decorative patterns, which differs from the above-mentioned first embodiment in that the chemical composition of the photochromic glaze is expressed in mass percent, specifically including: SiO 2 43.59%, Al 2 o 3 18.44%, Fe 2 o 3 0.14%, CaO 6.43%, MgO 6.88%, Na 2 O 3.03%, K 2 O 0.34%, ZnO 7.42%, TiO 2 0.11%, B 2 o 3 4.6%, BaO 8.2%, CuO 0.02%, AgBr 0.8%.

Embodiment 3

[0104] This embodiment provides a method for preparing photochromic ceramic tiles with a decorative pattern, which is different from the first or second embodiment above in that the patterned decorative layer and the color-changing decorative layer are applied by a parasitic screen printing process; The transparent glaze layer is applied by a bell jar glazing process.

[0105] Further, in this embodiment, the specific gravity of the glaze slurry of the color-changing decorative glaze is 1.50; the mesh number of the screen used in the alignment screen printing is 80 mesh.

[0106] Furthermore, in this embodiment, the glaze fineness of the transparent glaze is 3.2-3.8% on a 325-mesh sieve; the viscosity of the glaze slurry is 27-34s as measured by a Marsh funnel; the specific gravity of the glaze slurry is 1.68-1.75; Glazing amount: 220~320g / m 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com