Decorative pattern photochromic ceramic tile and preparation method thereof

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

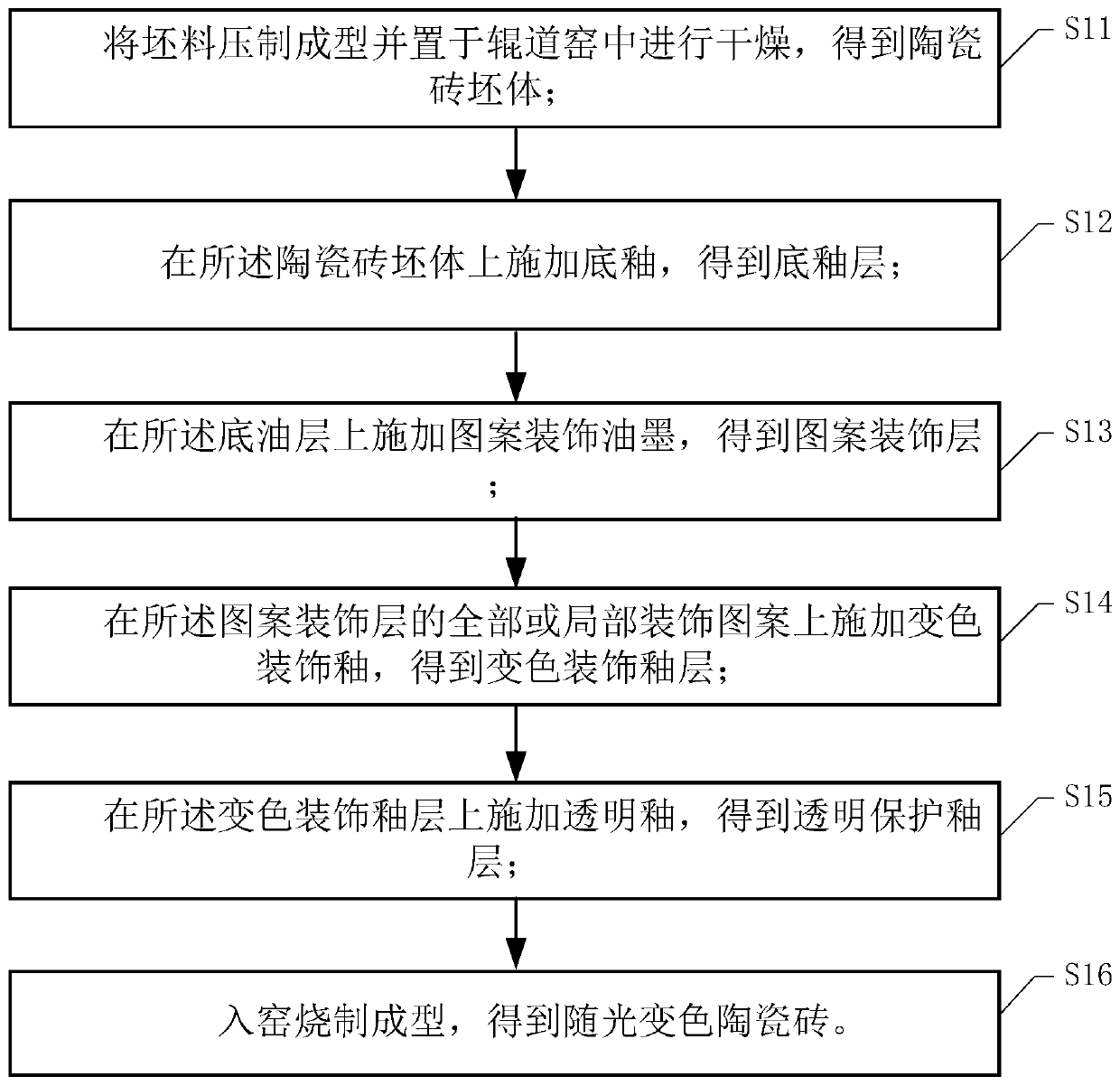

[0074] This embodiment provides a method for preparing a photochromic ceramic tile with a decorative pattern, comprising:

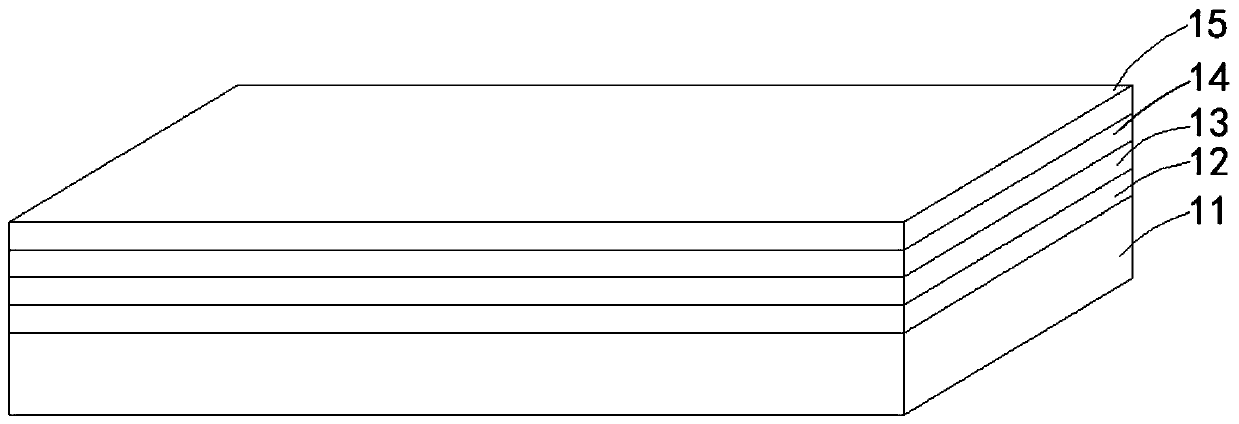

[0075] Step 11, pressing the blank and placing it in a roller kiln for drying to obtain a ceramic brick body;

[0076] Step 12, applying an underglaze on the ceramic tile body to obtain an underglaze layer;

[0077] Step 13, applying pattern decoration glaze ink on the bottom glaze layer to obtain a pattern decoration layer;

[0078] Step 14, applying a color-changing decorative glaze on all or part of the decorative pattern of the pattern decoration layer to obtain a color-changing decorative glaze layer;

[0079] Step 15, applying a transparent glaze on the color-changing decorative glaze layer to obtain a transparent protective glaze layer;

[0080] Step 16, firing in a kiln to obtain ceramic tiles that change color with light.

[0081] Further, the chemical composition of the photochromic glaze is in mass percent, including:

[0082] SiO 2 41.6~...

Embodiment 2

[0102] This embodiment provides a method for preparing photochromic ceramic tiles with decorative patterns, which differs from the above-mentioned first embodiment in that the chemical composition of the photochromic glaze is expressed in mass percent, specifically including: SiO 2 43.59%, Al 2 o 3 18.44%, Fe 2 o 3 0.14%, CaO 6.43%, MgO 6.88%, Na 2 O 3.03%, K 2 O 0.34%, ZnO 7.42%, TiO 2 0.11%, B 2 o 3 4.6%, BaO 8.2%, CuO 0.02%, AgBr 0.8%.

Embodiment 3

[0104] This embodiment provides a method for preparing photochromic ceramic tiles with a decorative pattern, which is different from the first or second embodiment above in that the patterned decorative layer and the color-changing decorative layer are applied by a parasitic screen printing process; The transparent glaze layer is applied by a bell jar glazing process.

[0105] Further, in this embodiment, the specific gravity of the glaze slurry of the color-changing decorative glaze is 1.50; the mesh number of the screen used in the alignment screen printing is 80 mesh.

[0106] Furthermore, in this embodiment, the glaze fineness of the transparent glaze is 3.2-3.8% on a 325-mesh sieve; the viscosity of the glaze slurry is 27-34s as measured by a Marsh funnel; the specific gravity of the glaze slurry is 1.68-1.75; Glazing amount: 220~320g / m 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com