Driving assembly and developing box

一种驱动组件、显影盒的技术,应用在显影盒领域,能够解决易损坏枢轴、驱动触头及回弹复位件安装不方便、驱动力传递不稳定等问题,达到操作简便、结构稳定、安装及拆卸方便的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

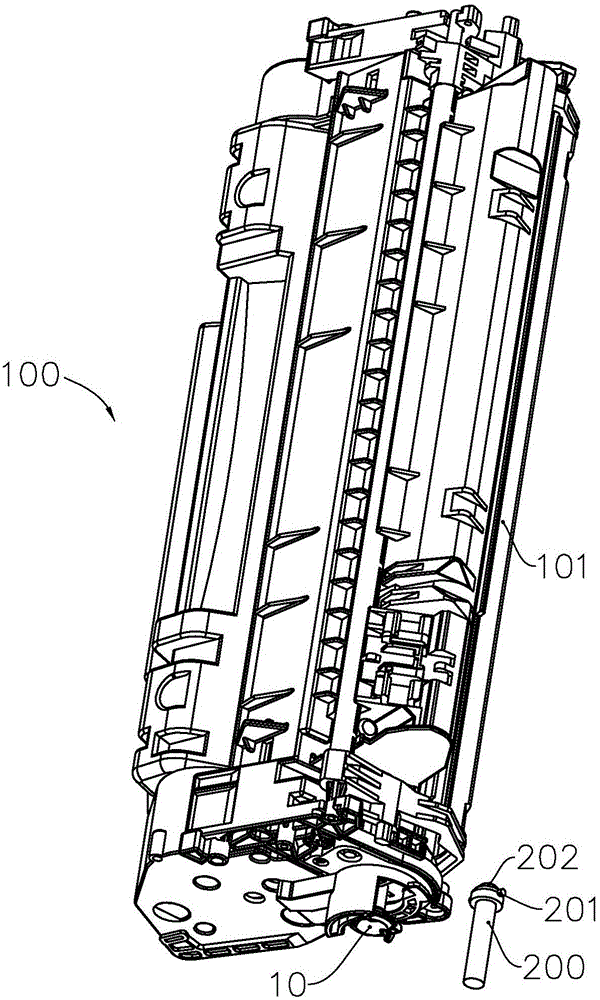

[0036] Such as figure 1 As shown, the developing cartridge 100 includes a cartridge body 101, and the driving assembly 10 is arranged at one end of the developing cartridge 100 in the longitudinal direction, so as to engage with the driving shaft 200 of the electrophotographic imaging device to transmit the driving force to the processing members in the developing cartridge 100, and the driving shaft The end of 200 has a radial protrusion 201 . There may be components such as a photosensitive drum, a developing roller, and a powder feeding roller in the developing cartridge. The driving assembly may be arranged at the end of the photosensitive drum or developing roller and be coaxial with it, so as to receive the driving force and directly drive the photosensitive drum or developing roller to rotate. Because it is not coaxial with any component, but it...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com