Sliding mode repetitive controller for motor servo system

A technology of repetitive controllers and servo systems, applied in general control systems, adaptive control, control/regulation systems, etc., and can solve problems such as complete suppression of non-periodic interference signals and chattering problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

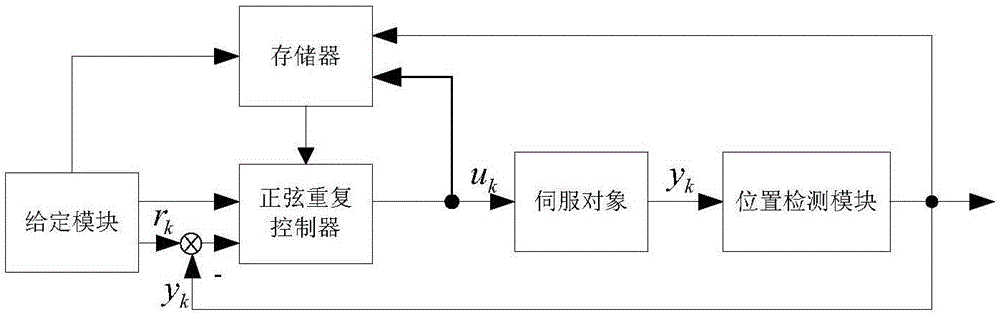

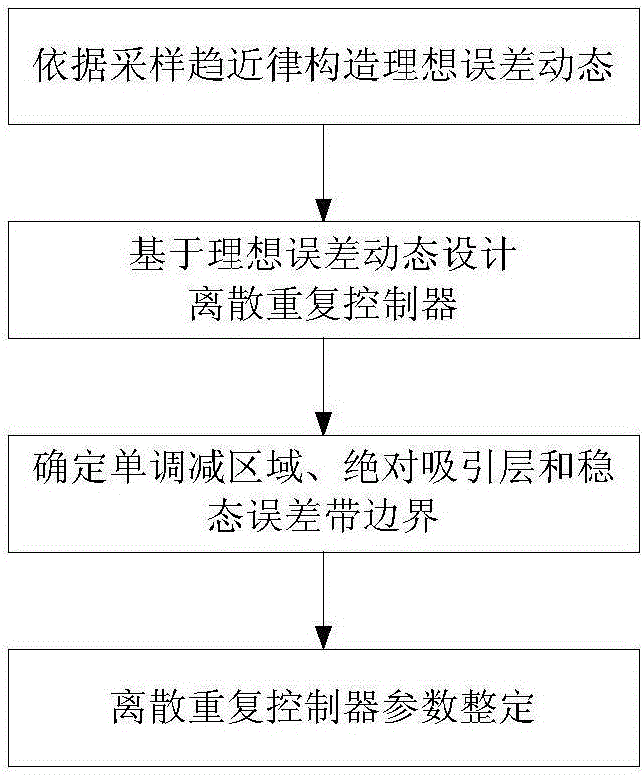

Method used

Image

Examples

example

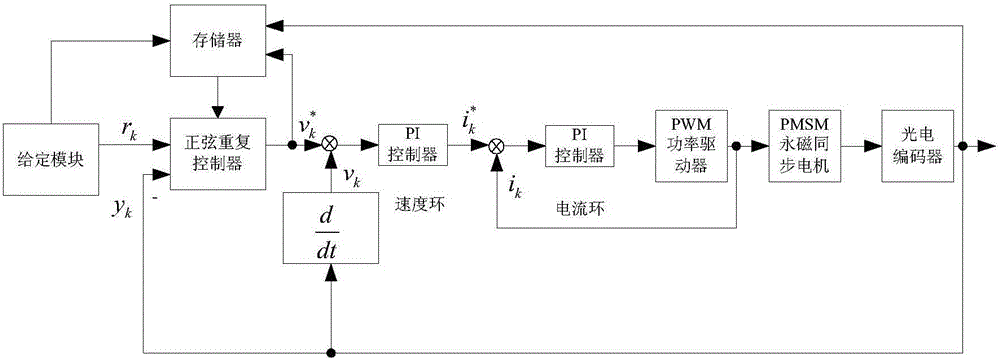

[0108] Example: Taking the motor servo system to perform repetitive tracking tasks as an example, its given position reference signal has periodic symmetry characteristics, and the motor sampling three-loop control, wherein the speed loop and current loop controllers are provided by the ELMO driver, and the repetitive design of the present invention The controller is used as the position loop controller in the motor three-loop control system, which is provided by the TMS320F2812 development board. Designing a position loop controller requires the establishment of mathematical models of servo objects other than the position loop, including current loops, speed loops, power drives, motor bodies, and detection devices. In this example, the effectiveness of the repetitive controller given by the present invention will be illustrated by numerical simulation.

[0109] For a position reference signal with periodic symmetry, when the servo system enters a steady state, the system dist...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com