Electromagnetic magnet with manual control and state detecting functions

A state detection and electromagnet technology, applied in the direction of electromagnets, electromagnets, circuits, etc. with armatures, can solve problems such as the inability of the electromagnet to work, the inability to judge whether the electromagnet is working, the surge in the temperature rise of the coil, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

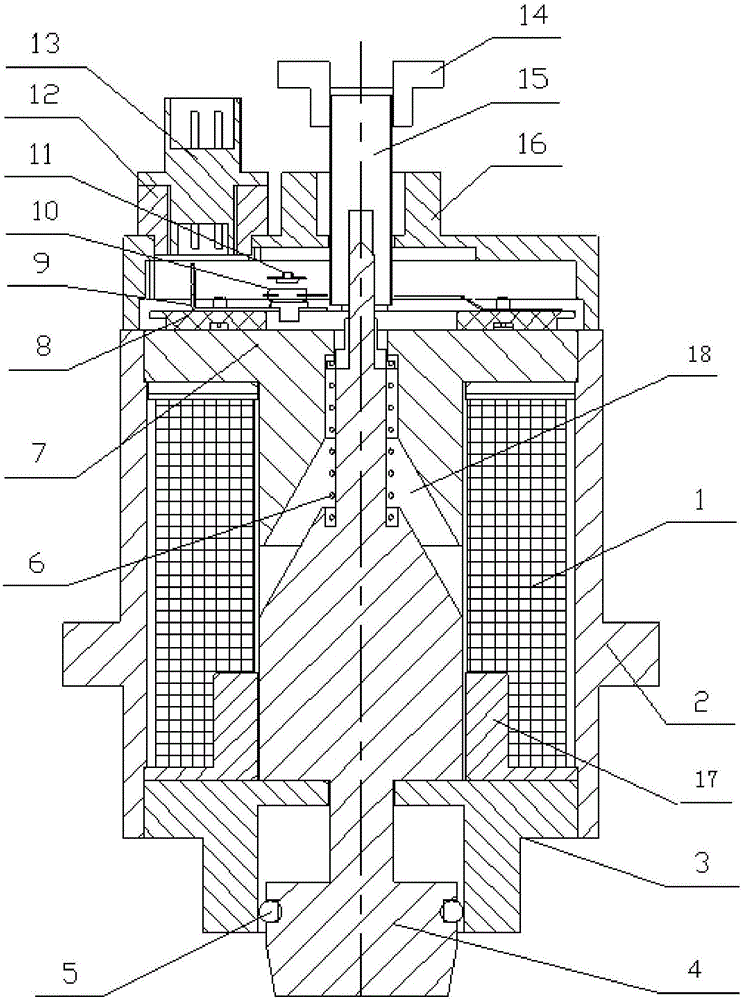

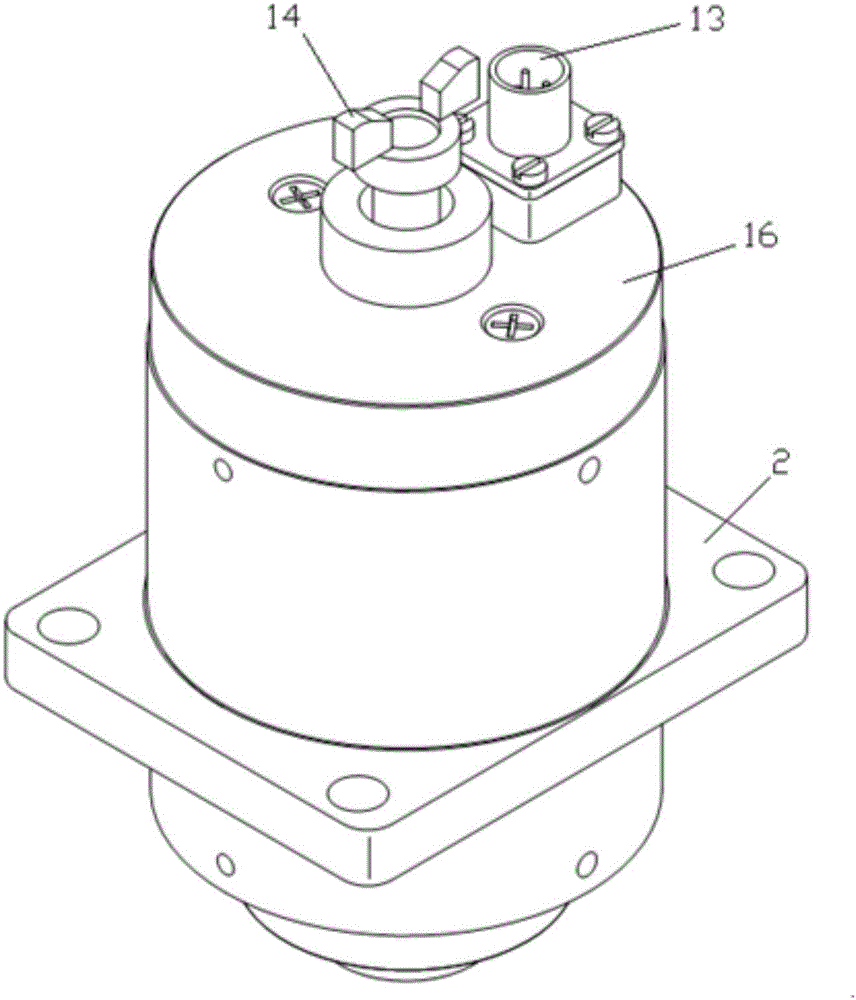

[0014] combined with figure 1 , 2 , 3, 4 describe an embodiment of the present invention.

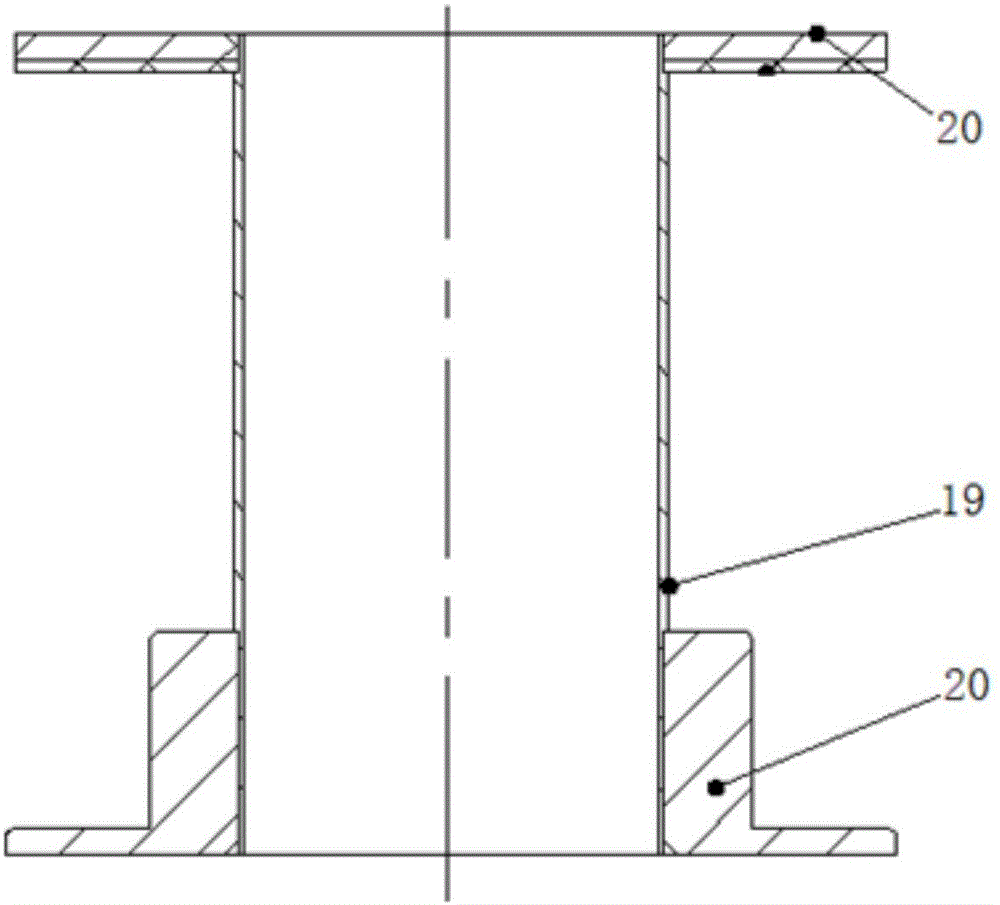

[0015] A double-coil electromagnet with manual control and state detection has a casing 2, a coil frame 17 is installed in the casing 2, a coil 1 is wound on the coil frame 17, and the upper end of the casing 2 is equipped with a "T " type iron core 7, the lower end is equipped with "T" type cover plate 3; There is a through hole 18 whose lower end is a tapered mouth; the base 8 is riveted with a static reed 9, a moving reed 10 and a state detection reed 11, and the static reed 9 and the moving reed 10 are normally closed contacts. The moving reed 10 and the state detection reed 11 are normally open contacts, and the base 8 is equipped with an inverted "T"-shaped dust cover 16; the coil frame 17 is inserted with an armature 4, and the upper part of the armature 4 It is in the shape of a tapered rod, the taper is adapted to the taper mouth, the rod is inserted into the through hole 18...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com