Rotatable end of dose feedback mechanism

A dose and rotating tower technology, applied in the direction of medicine equipment, infusion sets, other medical equipment, etc., can solve the problems of plunger driving parts movement, complexity and error indication

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

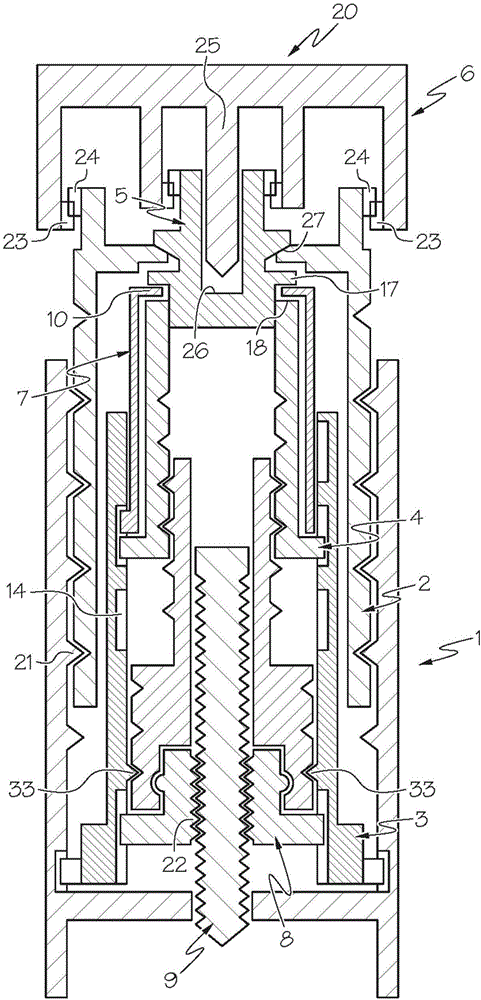

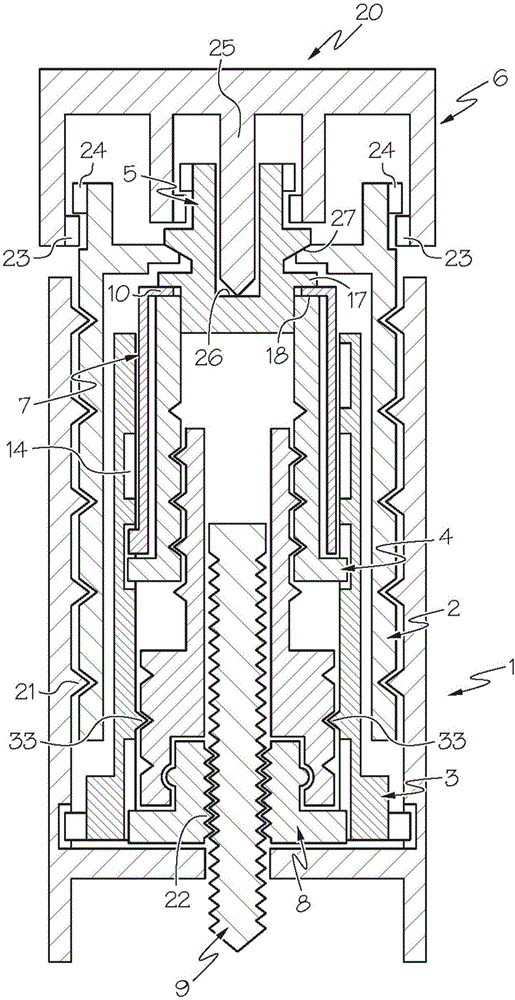

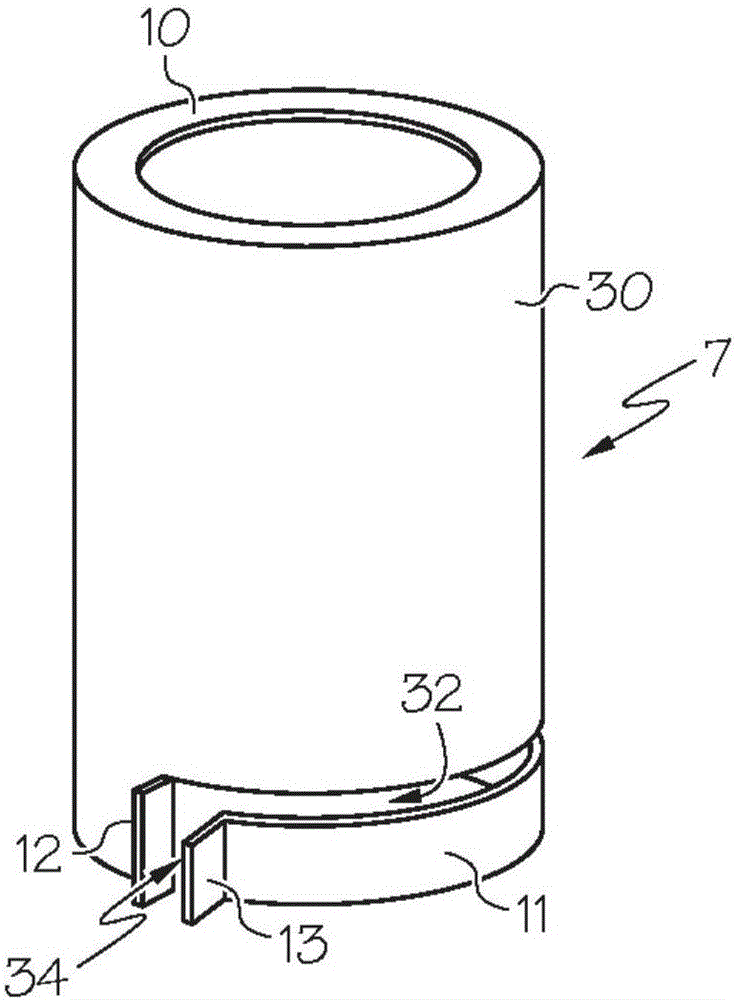

[0051] In the following, the term "main axis" defines a common axis for the mainly tubular part and for the entire injection device. First, although the description includes only the parts relevant to understanding the function of the signal characteristics of the end-of-dose notification mechanism, however, the accompanying picture Other parts may be shown that may be part of an injection device including this feature. figure 1- 4 and Figure 9- 12 The injection device disclosed is similar to the injection device disclosed in WO 2012 / 037938 A1 which is incorporated herein by reference, whereas Figure 6- The injection device of 8 is similar to the injection device disclosed in WO 2005 / 018721 which is hereby incorporated by reference.

[0052] The terms "upper", "lower", "upper", "lower", "upward" and "downward" refer to the attached picture rather than by reference to usage.

[0053] In all embodiments, the screw abuts a plunger in a drug-filled cartridge, and downward m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com