Hydrocyclone

The technology of a cyclone and a cylindrical body is applied in the field of mining equipment, which can solve the problems of wear of the bottom flow pipe, high pressure and fast flow rate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

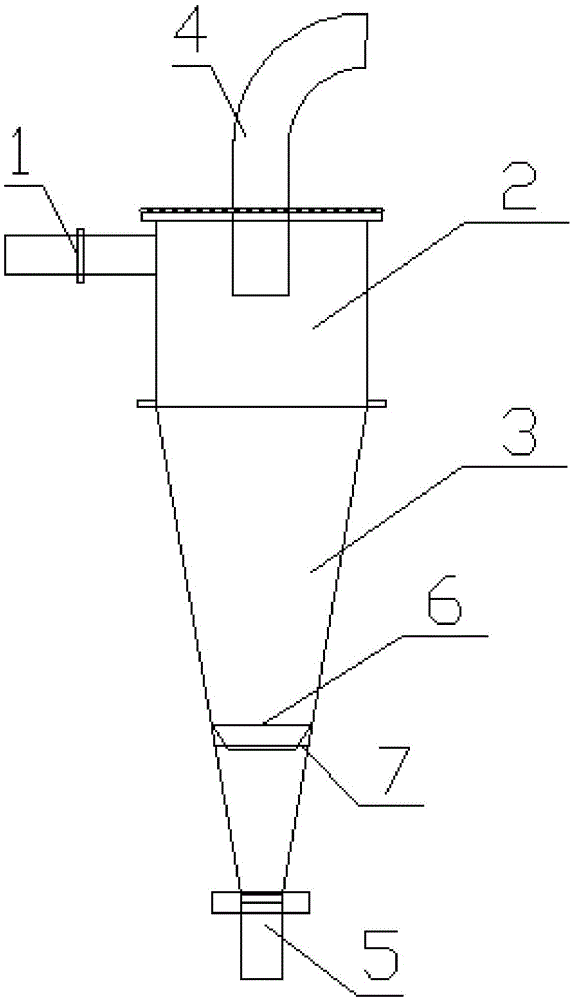

[0012] The present invention will be further described below in conjunction with accompanying drawing.

[0013] Such as figure 1 As shown, a cyclone includes a cylindrical cylinder 2 and a wear-resistant conical cylinder lining 6. The bottom end of the cylindrical cylinder 2 is fixedly connected to the upper end of the conical cylinder 3 through a flange, and the lower end of the conical cylinder 3 is connected with The bottom flow pipe 5, the upper part of the side wall of the cylinder body 2 is provided with a horizontal feed pipe 1, the feed pipe 1 is tangentially matched with the cylinder body 2, the upper end of the cylinder body 2 is provided with a cover plate, and the center of the cover plate An overflow pipe 4 is provided, and the wear-resistant conical lining 6 is fixedly arranged in the lower area of the inner side of the conical cylinder 3. The outer diameter of the large-diameter upper end of the wear-resistant conical cylinder 6 is the same as the inner diamet...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap