Vehicle Front Structure

A front structure, vehicle technology, applied in the direction of vehicle components, substructure, superstructure, etc., to achieve the effect of improving crash performance, increasing bending rigidity, and increasing yield strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

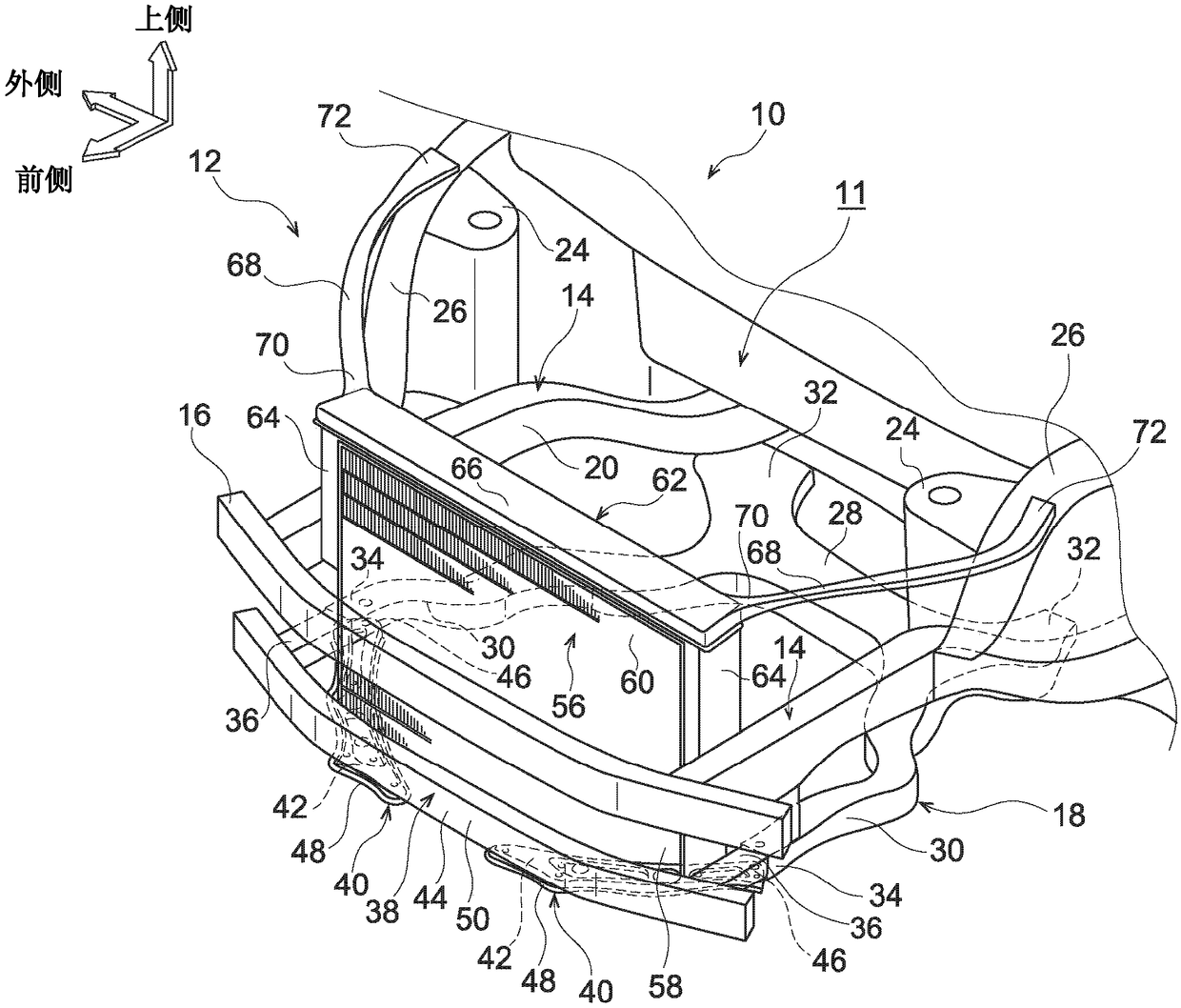

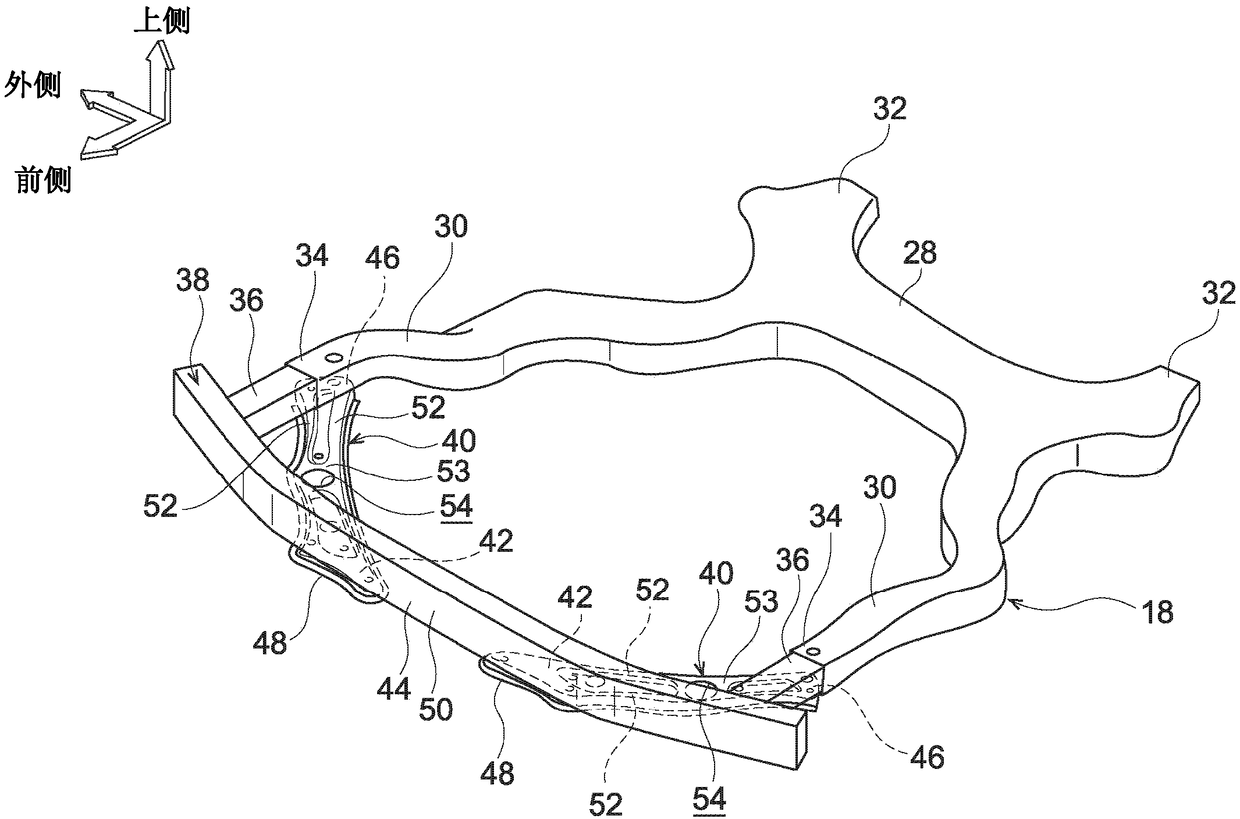

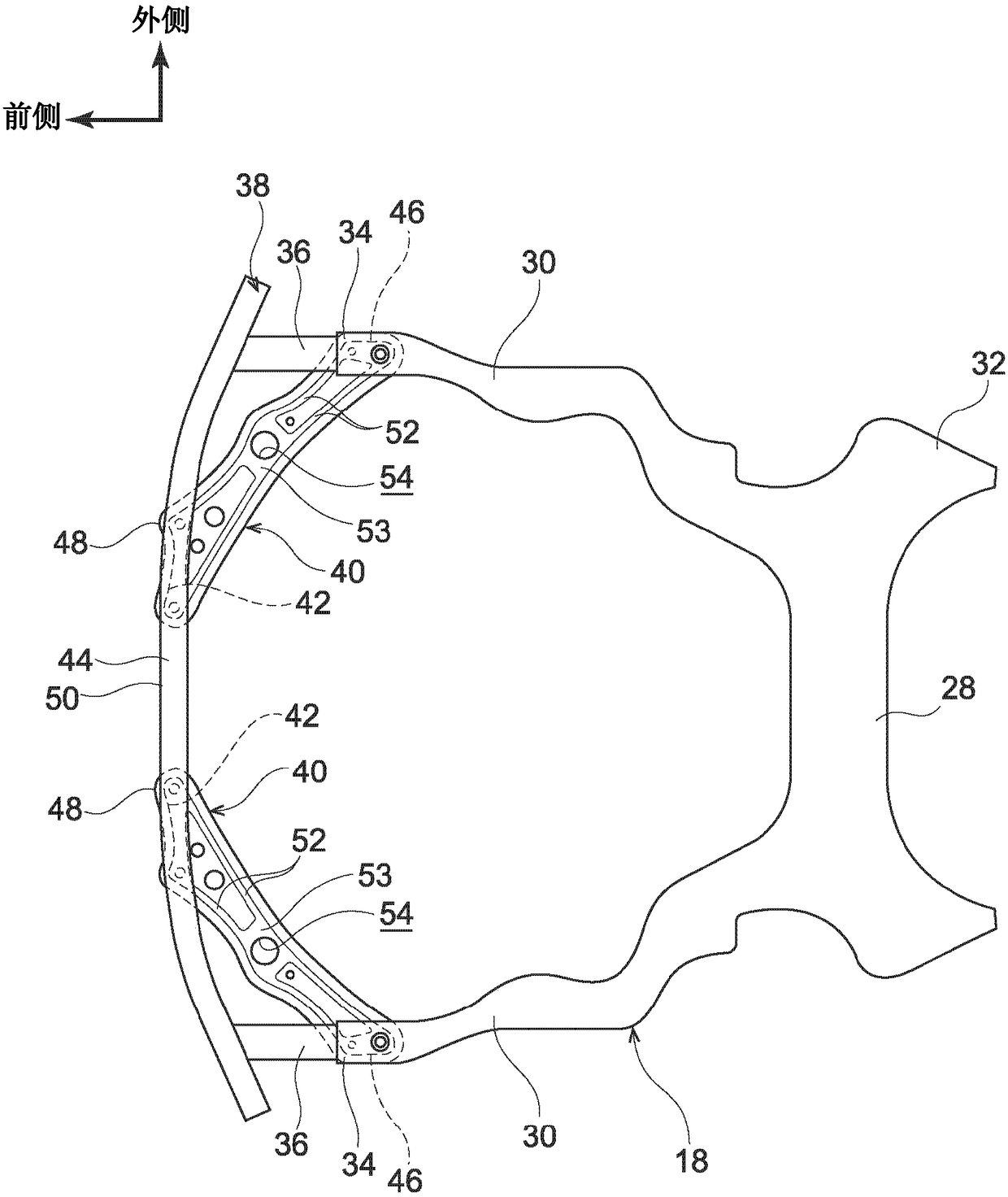

[0018] Below by using Figure 1 to Figure 3 Embodiments of the vehicle front structure related to the present invention are described. Note that arrow FR shown in these drawings indicates the vehicle longitudinal front side, arrow OUT indicates the vehicle transverse outer side, and arrow UP indicates the vehicle vertical direction upper side.

[0019] like figure 1 As shown, an engine room 11 in which an unshown engine unit is accommodated is provided at a front portion 12 of the vehicle 10 . A front side member 14 serving as a pair of left and right side members and having an interval therebetween and extending in the vehicle longitudinal direction, and a bumper reinforcement 16 mounted to front end portions of the pair of left and right front side members 14 are provided. Inside the engine compartment 11 . In addition, the front portion 12 of the vehicle 10 has a suspension beam 18 to which an unshown suspension arm, a steering gear box, and the like are mounted.

[002...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com