Blade set, hair cutting appliance, and related manufacturing method

一种毛发切割、刀片组的技术,应用在电操作毛发切割器具,制造用于毛发切割器具的固定刀片和刀片组,固定刀片领域,能够解决不舒服、引导准确度切割准确度降低、不是很人性化等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

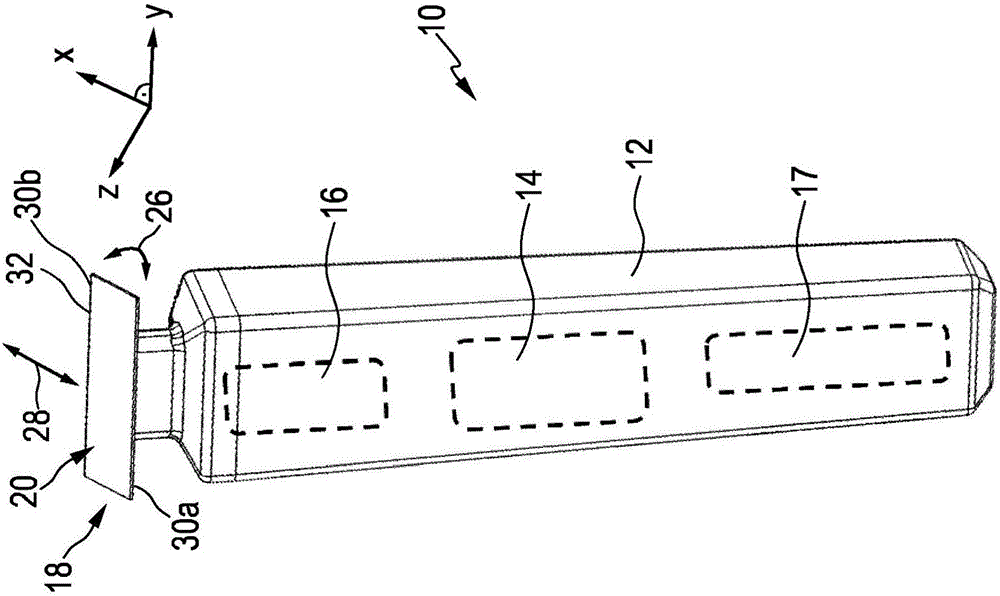

[0093] figure 1 An exemplary embodiment of a hair cutting appliance 10 , in particular an electric hair cutting appliance 10 , is schematically illustrated in a simplified perspective view. Cutting instrument 10 may include a housing or more specifically a housing portion 12, a motor indicated by a dashed box 14 in housing portion 12, and a drive mechanism or drive train indicated by a dashed box 16 in housing portion 12. . To provide power to the motor 14, at least in some embodiments of the cutting instrument 10, an electrical battery, indicated by a dashed box 17 in the housing portion 12, may be provided, such as, for example, a rechargeable battery, a replaceable battery, or the like. However, in some embodiments, the cutting implement 10 may be further provided with a power cable for connection to a power source. A power connector may be provided in addition to or as an alternative to the (internal) power supply battery 17 .

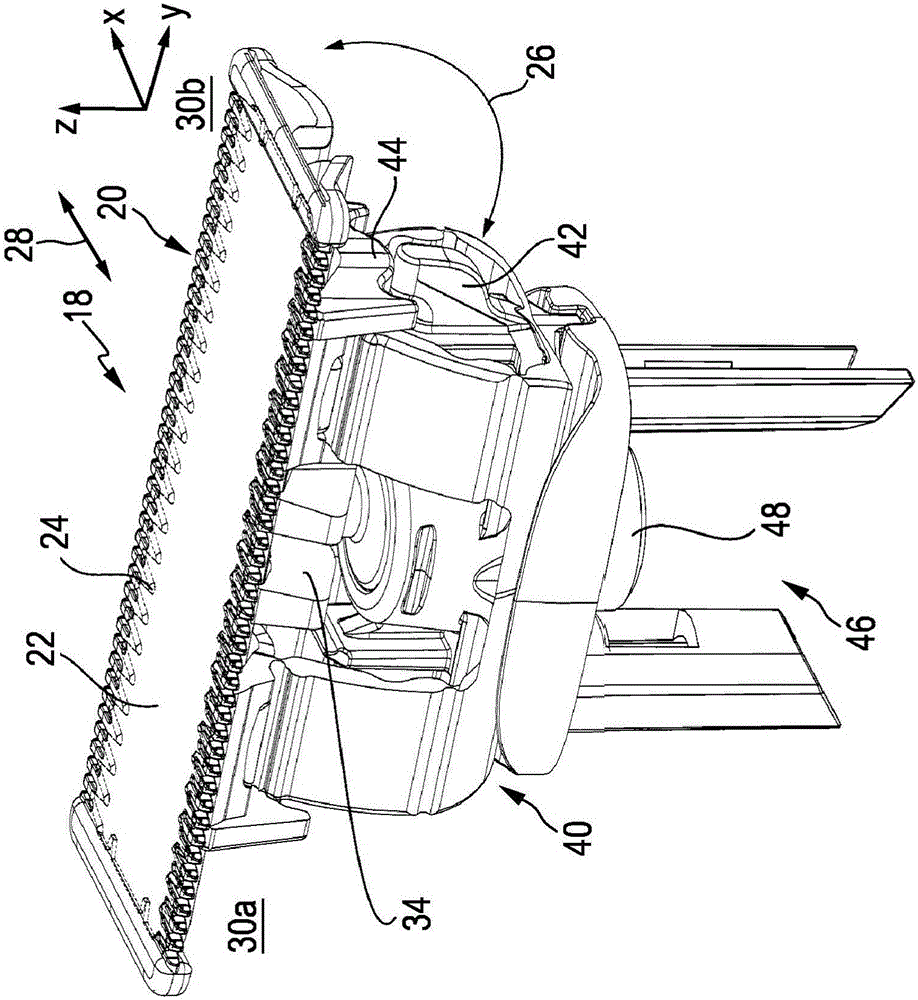

[0094] The cutting implement 10 may furth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com