Utility vehicle tyre

A technology for multi-purpose vehicles and tires, applied in the direction of vehicle components, tire parts, reinforcement layers of pneumatic tires, etc., can solve the problems of expensive, heavy tire production, etc., achieve high load capacity, ensure adhesive properties, and improve tearing The effect of the characteristic

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

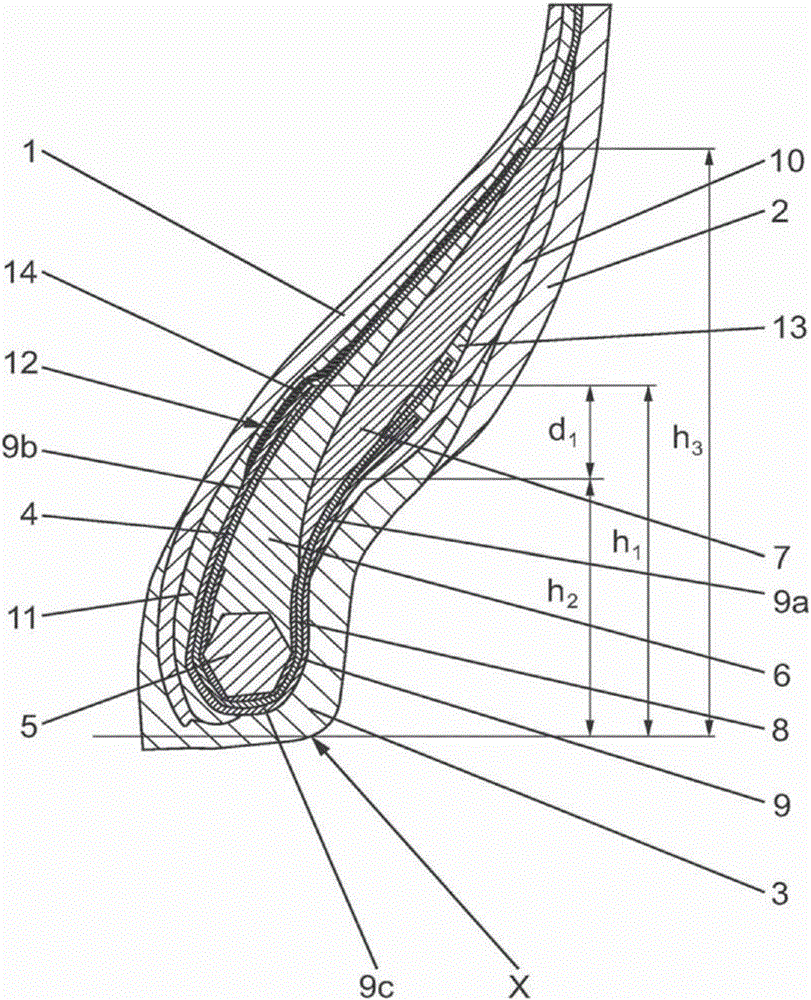

[0013] The height hi (i=1 to 3) specified below is measured in the radial direction from a line extending through the apex X of the rim in the axial direction.

[0014] Among the components of utility vehicle tires, figure 1 Single-ply or multi-ply carcass inserts 4 showing a gas-impermeable inner layer 1, sidewalls 2, corner profiles 3, steel cords or similar strength materials as reinforcing members, tires composed of tensile steel wires The bead core 5 , and the two core profiles 6 and 7 sitting on the bead core 5 . The sidewall 2 overlaps the corner profile 3 on the outside.

[0015] The core profiles 6 and 7 can be produced from the same or different rubber mixtures. A flipper 8 consisting of a textile reinforcement preferably embedded in rubber is laid around the bead core 5 so as to embed a carcass extending from a belt (not shown) and wrapped around the bead core 5 from the inside out. The part 4 is separated from the bead core 5 , whereby direct contact between the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com