A kind of inner wall connecting structure and construction method thereof

A technology for connecting structures and walls, which is applied in the direction of walls, building components, building structures, etc., can solve the problems of poor structural strength of walls, difficulty in discharging, and difficulty in guaranteeing the quality of walls, etc., so as to strengthen the connection stability and improve the support The effect of reducing the strength and difficulty of installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, so as to help understand the content of the present invention.

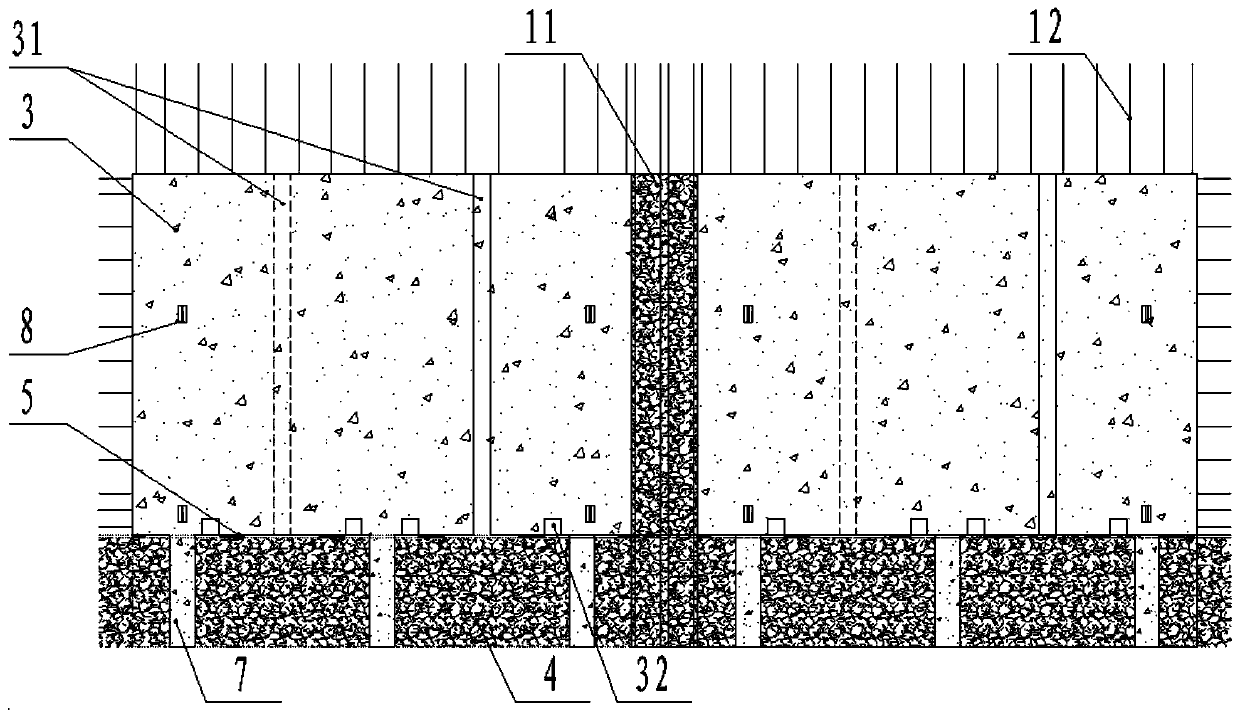

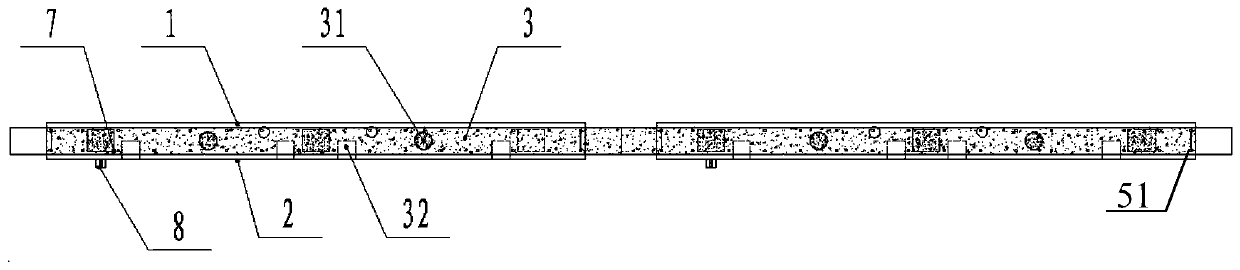

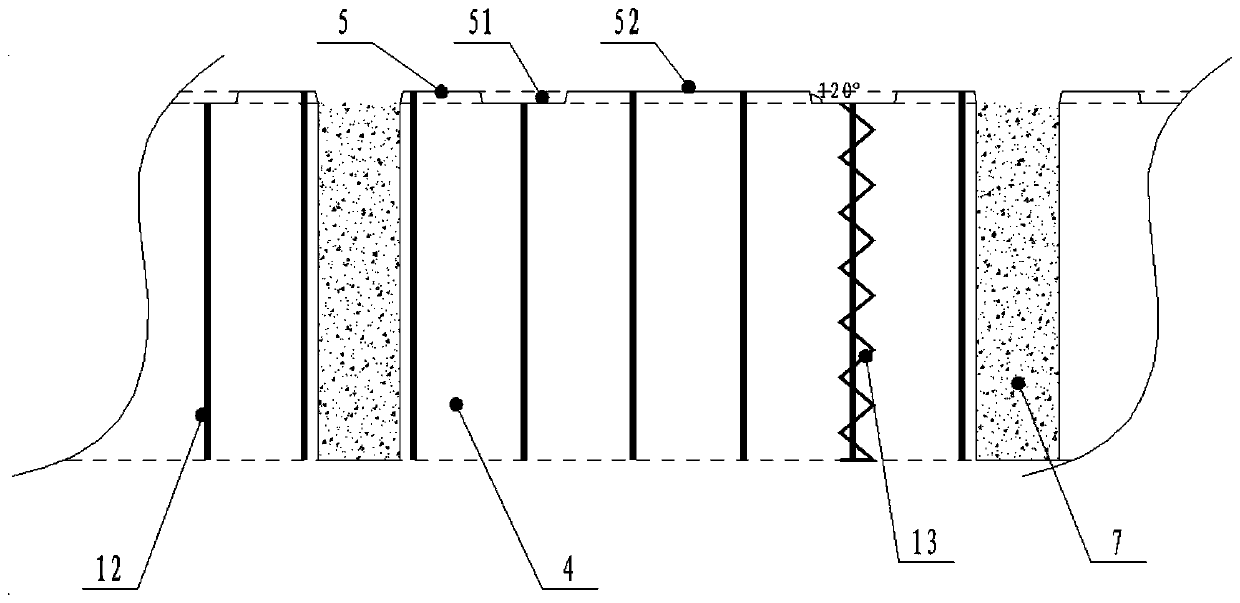

[0039] Such as Figure 1-2 As shown, an internal wall connection structure, wherein each prefabricated wall is mainly composed of the first wall 1, the second wall 2 and is sandwiched between the first wall 1 and the second wall 2 The support body is composed of a certain distance between the bottom of the support body and the bottom of the first wall body 1 and the second body of wall body 2, so as to construct a concrete that fills the entire bottom space between the first body of wall body 1 and the second body of wall body 2 The cast-in-place space 4 is at least provided with longitudinal steel bars in the cast-in-place space 4, so it can become a concrete cast-in-place anchorage space again. The top of the cast-in-place space 4 is preferably a plane, and the support body and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com