A horizontal compressor and temperature adjustment equipment

A compressor and horizontal technology, which is used in the field of horizontal compressors and temperature adjustment equipment, can solve the problems of inability to seal, the sliding vane and the cylinder are not tightly sealed, and the pressure is reduced.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] One of the cores of the present invention is to provide a horizontal compressor to ensure that the sliding vane can be extended smoothly when the compressor is started, and the sliding vane and the cylinder can maintain a proper adhesion force during normal operation, thereby improving compression The reliability of the machine.

[0036] Another core of the present invention is to provide a temperature regulating device with the above-mentioned horizontal compressor.

[0037] In order to enable those skilled in the art to better understand the solution of the present invention, the present invention will be further described in detail below with reference to the accompanying drawings and specific embodiments.

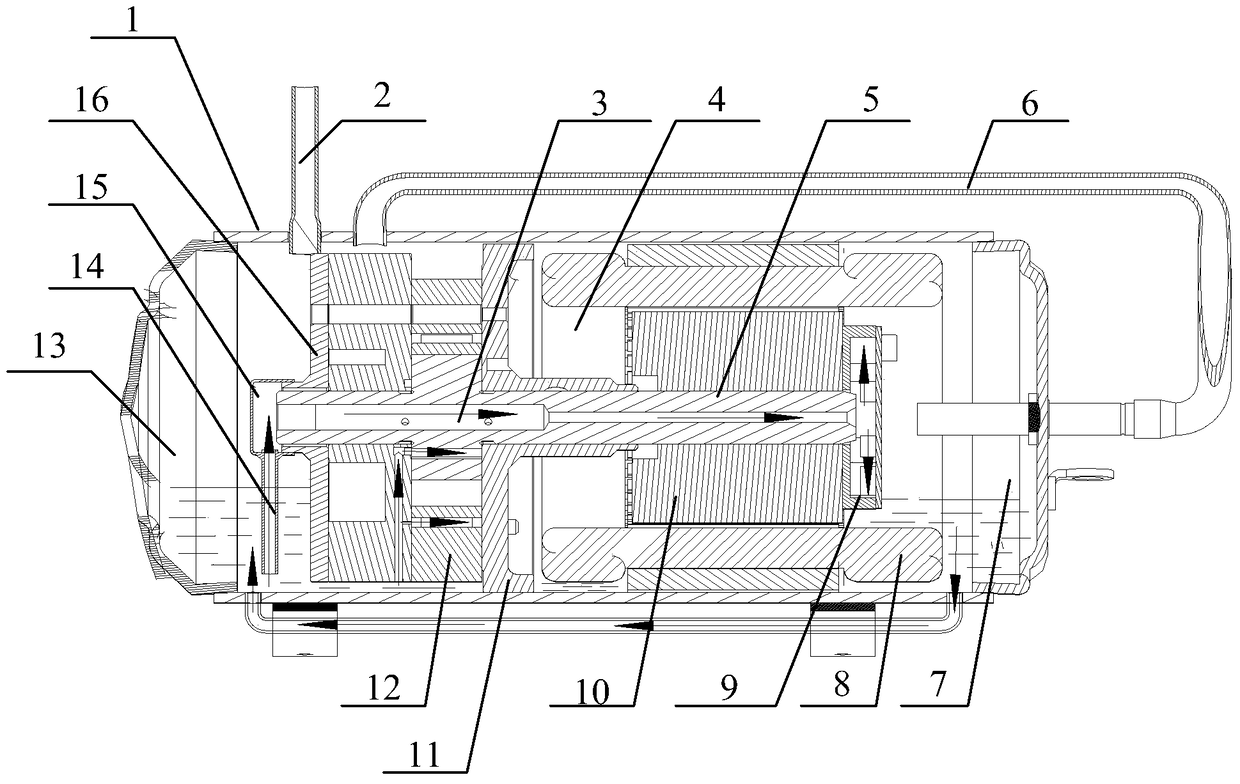

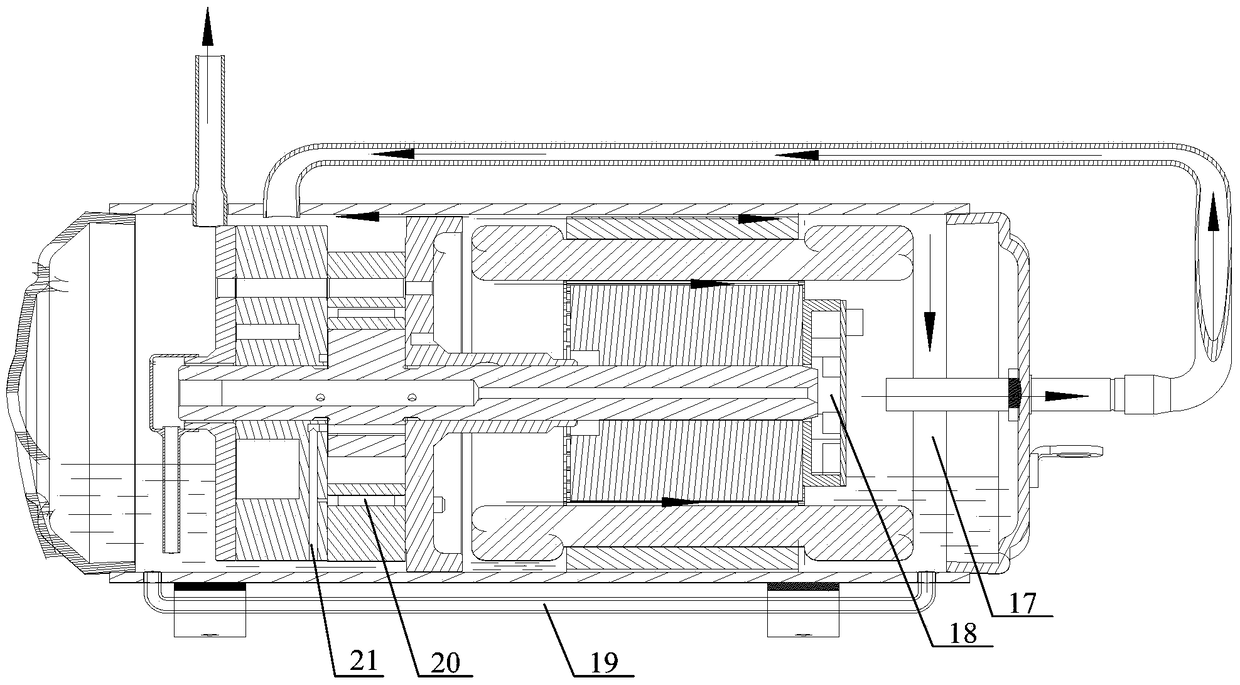

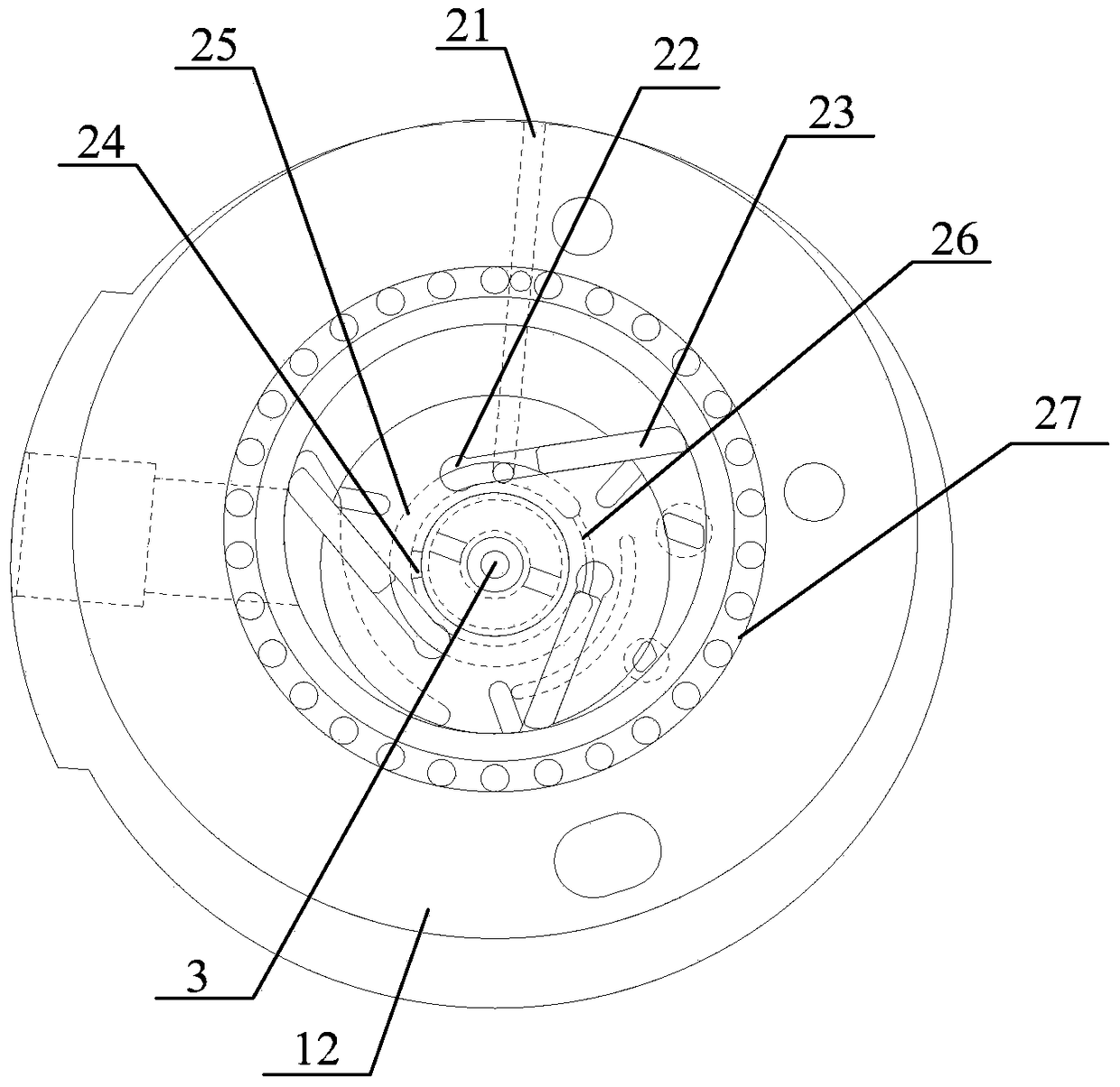

[0038] Please refer to Figure 1 to Figure 4 , figure 1 Is a schematic cross-sectional view of a horizontal compressor showing the flow direction of lubricating oil in an embodiment of the present invention, figure 2 Is a schematic cross-sectional view of a horizontal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com