Self-adaptive adjustment method for suction nozzle of chip mounter

A technology of self-adaptive adjustment and placement machine, which is applied to electrical components, electrical components, etc., can solve the problems of poor suction of nozzle components and unstable working conditions, and achieve the effect of saving labor monitoring costs and improving production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The principles and features of the present invention will be described below with reference to the accompanying drawings. The examples are only used to explain the present invention, but not to limit the scope of the present invention.

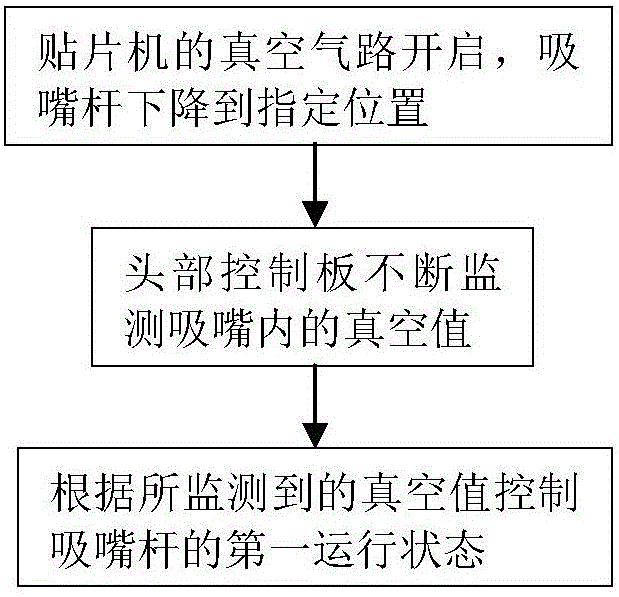

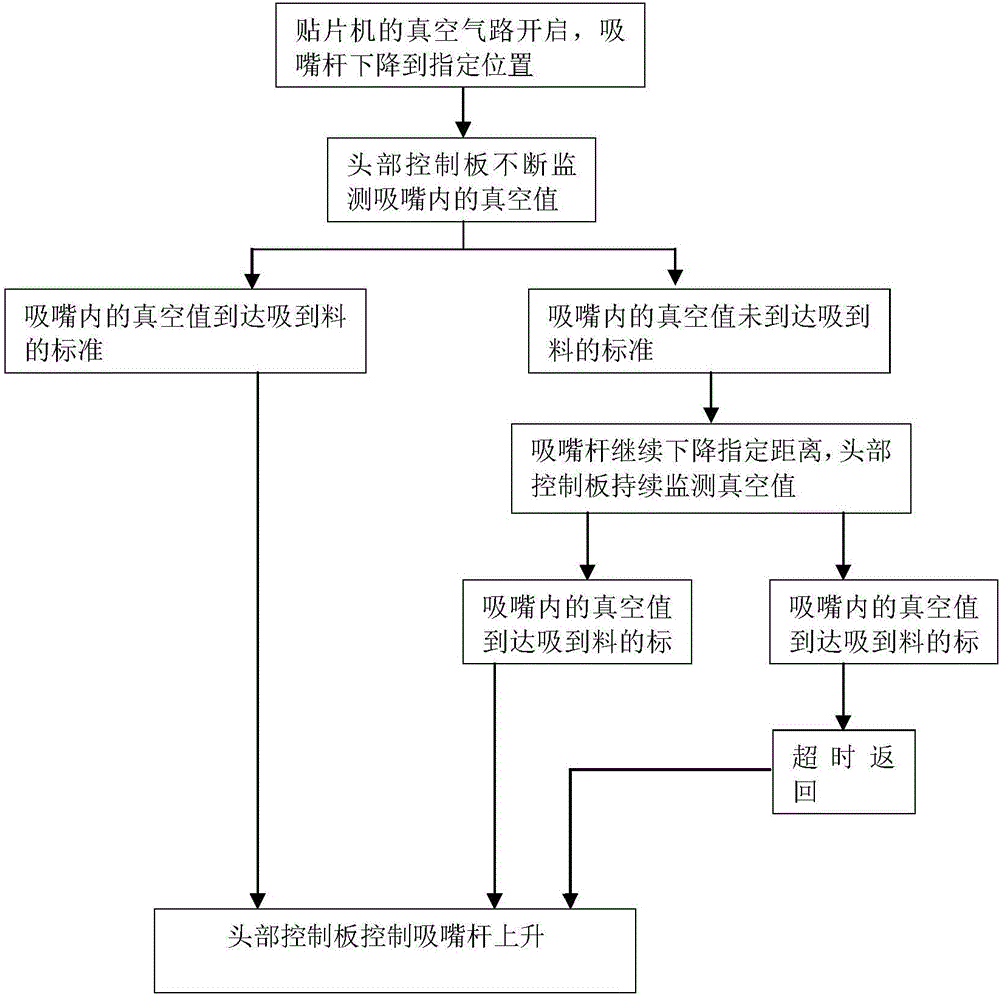

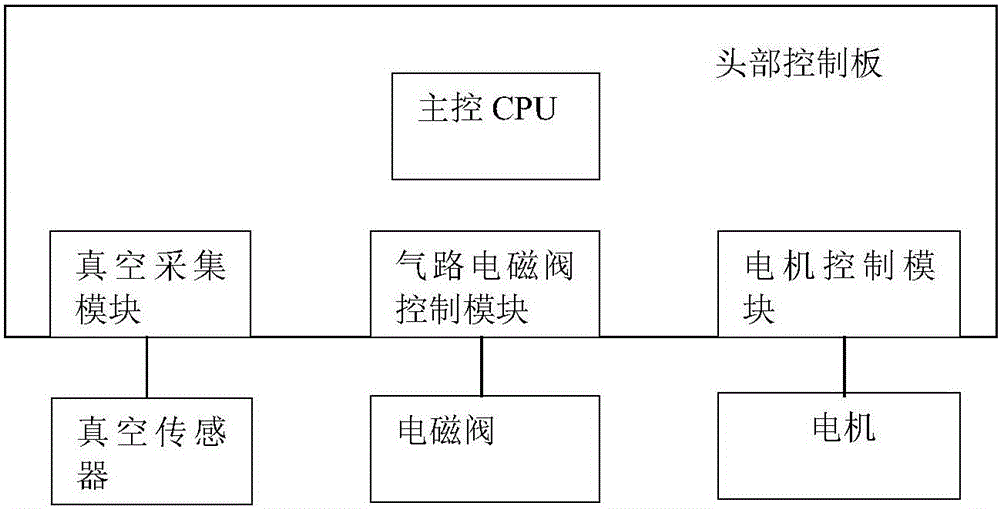

[0022] figure 1 It is a schematic structural diagram of a nozzle self-adaptive adjustment method of a placement machine of the present invention, such as figure 1 As shown in the figure, the present invention is an adaptive adjustment method for the suction nozzle of the placement machine. The vacuum air path of the placement machine is opened, and the suction nozzle rod is lowered to the designated position; the head control board continuously monitors the vacuum value in the suction nozzle, and according to the The monitored vacuum value controls the first operating state of the nozzle rod.

[0023] The nozzle rod is lowered to the specified position, which can be obtained according to the experience value. Under the normal condition...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com