Vertical type partition placing machine

A vertical, clapboard technology, applied in the direction of conveyor objects, transportation and packaging, can solve the problems of poor feeding and grasping mechanism accuracy, small number of clapboards, and failure to place clapboards, etc., to achieve accurate and stable feeding. The effect of realizing the whole process of automatic operation and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

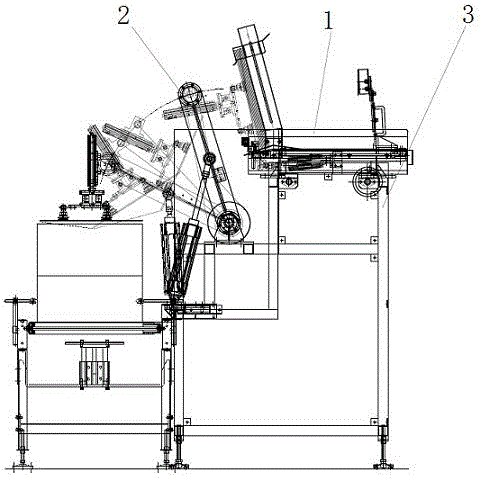

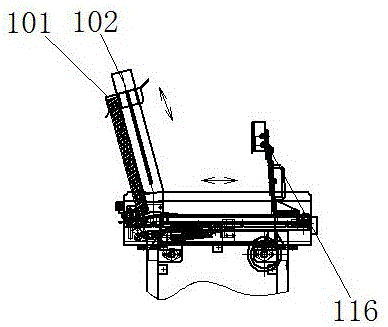

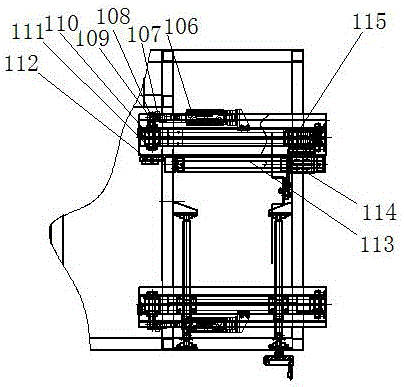

[0017] Such as Figure 1 to Figure 6 As shown, the vertical partition placing machine includes a vertical material storage tank 1, a grabbing mechanism 2 and a frame body 3, and the vertical material storage tank 1 and the grabbing mechanism 2 are respectively installed on the frame body 3, and the vertical material storage tank Groove 1 comprises pressure box plate 101, height adjustment slide rail 102, width adjustment hand wheel 103, screw nut 104, belt seat bearing 105, feed cylinder 106, Y-shaped joint 107, one-way bearing 108, first drive shaft 109, the second A synchronous toothed belt pulley 110, the first synchronous toothed belt 111, sensor 112, push box plate slide rail 113, slide seat 114, toothed plate 115, push box plate 116 and leading screw 117, and press box plate 101 passes through the first A slider slides on the height adjustment slide rail 102, the width adjustment hand wheel 103 is connected with the screw 117, the bearing with seat 105 is installed at th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com