A connection device for fiber composite tendons

A connecting device and a technology of composite bars, which are applied in the direction of buildings, building reinforcements, and building components, can solve the problems of failure of fixed joints of reinforcing bars, the inability to apply fiber composite bars to on-site construction of steel bars, and the decline in the bearing capacity of concrete structures To avoid surface structure damage, avoid fixed connection failure, improve performance and service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to make the technical solutions and advantages of the present invention clearer, the present invention will be described in further detail below with reference to the accompanying drawings and specific embodiments.

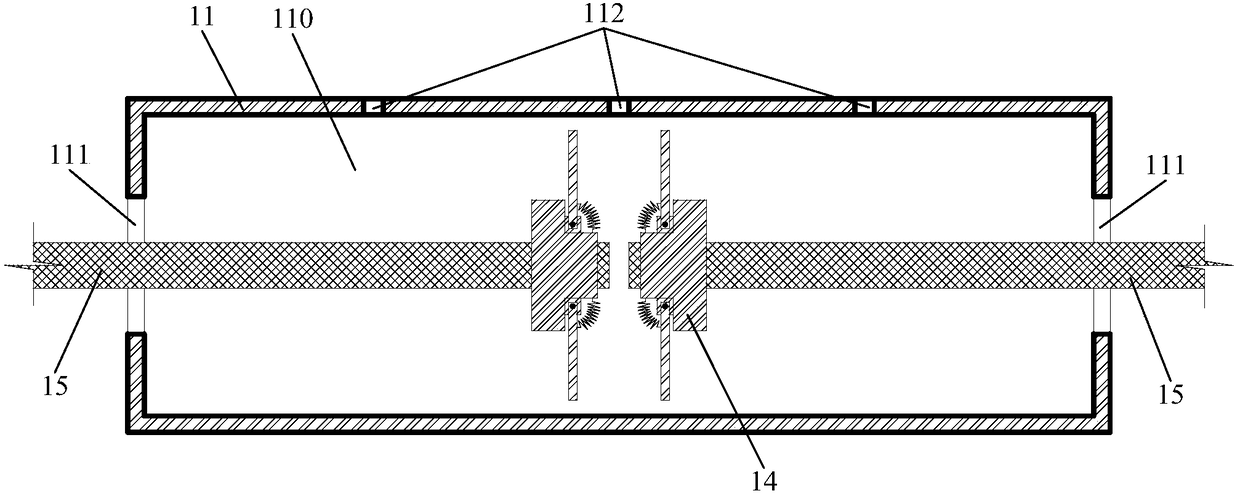

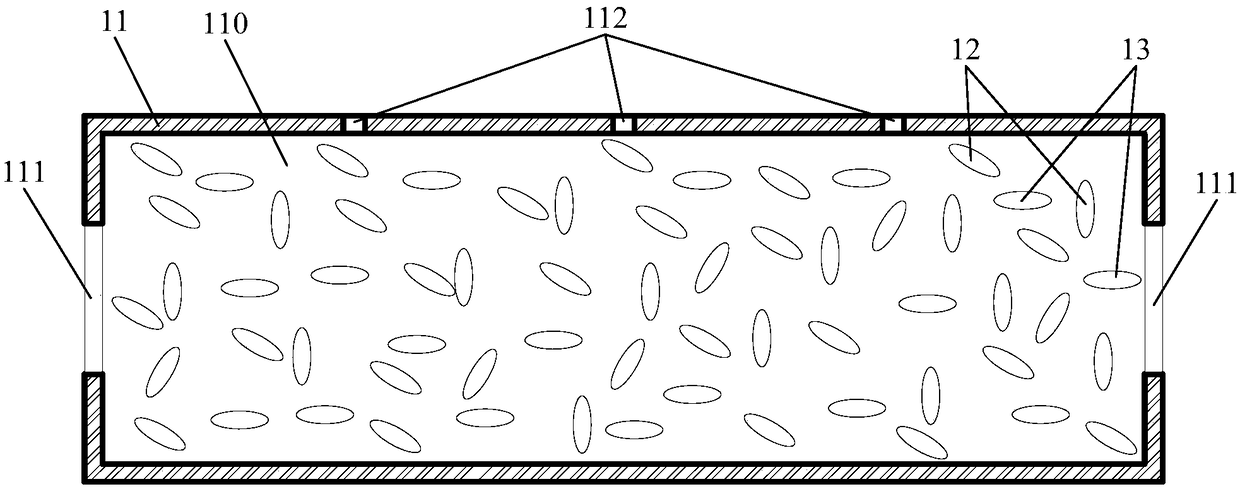

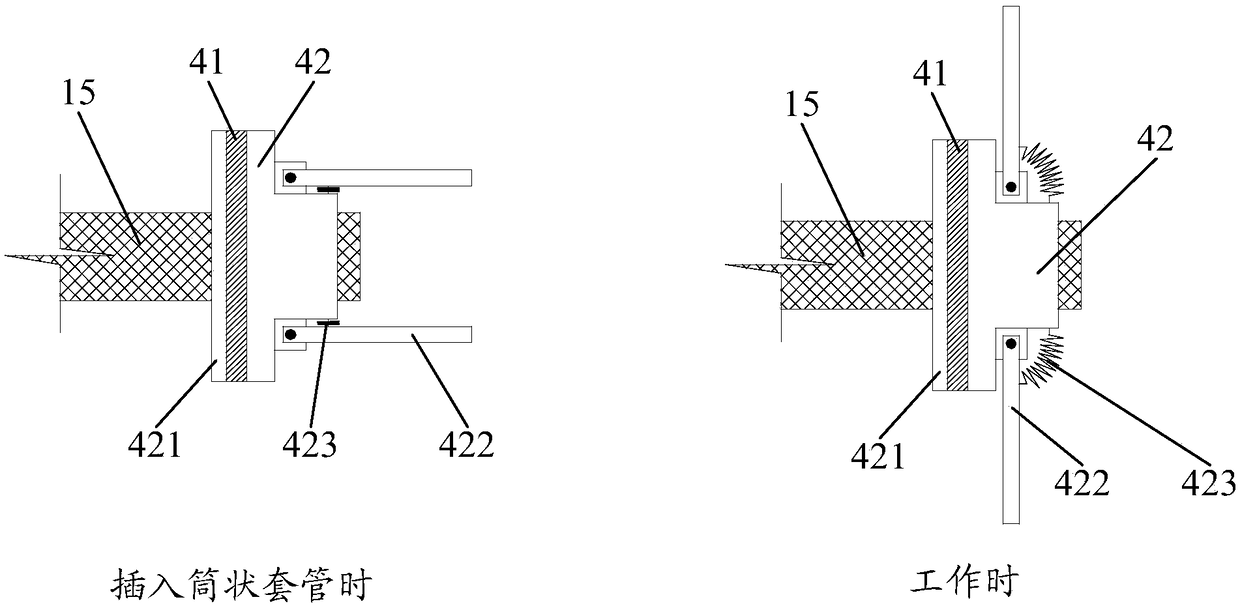

[0035] figure 1 It is a schematic structural diagram of the connecting device of the fiber composite bar in the embodiment of the present invention. figure 2 It is a schematic cross-sectional view of the cylindrical sleeve in the embodiment of the present invention. like figure 1 , figure 2 As shown, the connecting device of the fiber composite bar in the present invention includes: a cylindrical sleeve 11, at least one adhesive capsule 12, at least one curing agent capsule 13 and two anchoring devices 14;

[0036] The interior of the cylindrical sleeve 11 has a cavity 110; the two ends of the cylindrical sleeve 11 are respectively provided with through holes 111;

[0037] The adhesive capsule 12 and the curing agent capsule 13 are arranged i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com